Dust-dirt separation device and dust collector

A technology for separating devices and dust. It is applied in the installation of vacuum cleaners, suction filters, and electrical equipment. It can solve problems such as easy damage, and achieve the effect of improving user experience and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

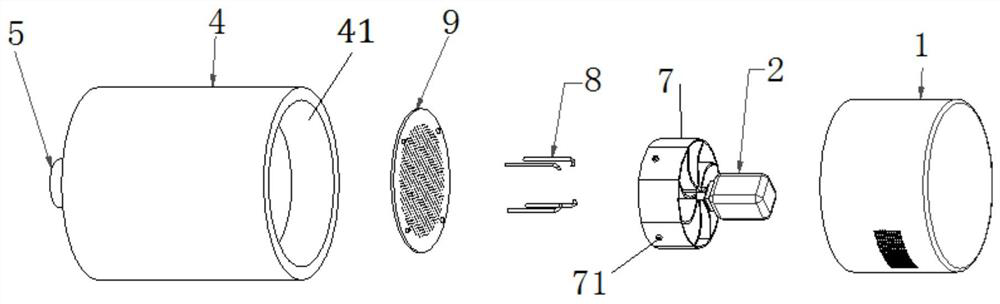

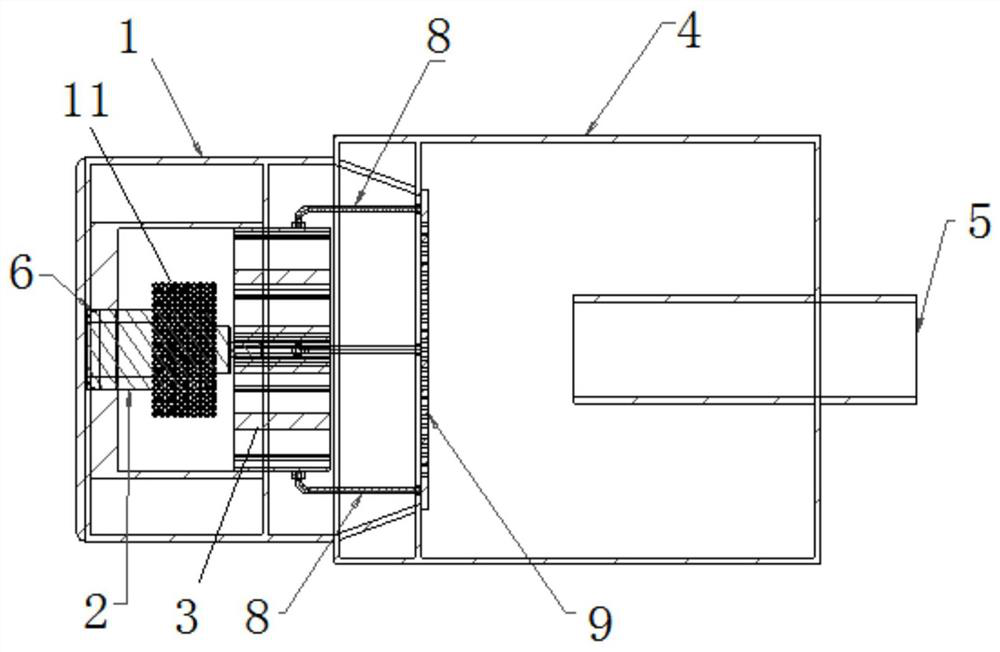

[0044] This embodiment provides a dust and dirt separation device, such as Figure 1-Figure 5 shown, including:

[0045] The main body 1 is provided with a vacuum motor inside; specifically, the main body 1 itself is provided with a cylindrical structure, and a cavity is provided inside the main body 1;

[0046] The wind wheel 3 is detachably arranged on the vacuum motor 2;

[0047] Specifically, by setting the wind wheel 3, the outside air can be sucked into the main body 1, and the air will carry dust, so as to facilitate the subsequent operation of separating the dust from the air.

[0048] The dust collecting chamber 4 is detachably arranged on the main body 1, and the dust collecting chamber 4 is provided with an opening 41, the main body 1 is connected with the dust collecting chamber 4 through the opening 41, the An air inlet 5 is arranged on the dust collecting chamber 4;

[0049] like figure 2 and image 3 As shown, an opening 41 is provided on the left side of ...

Embodiment 2

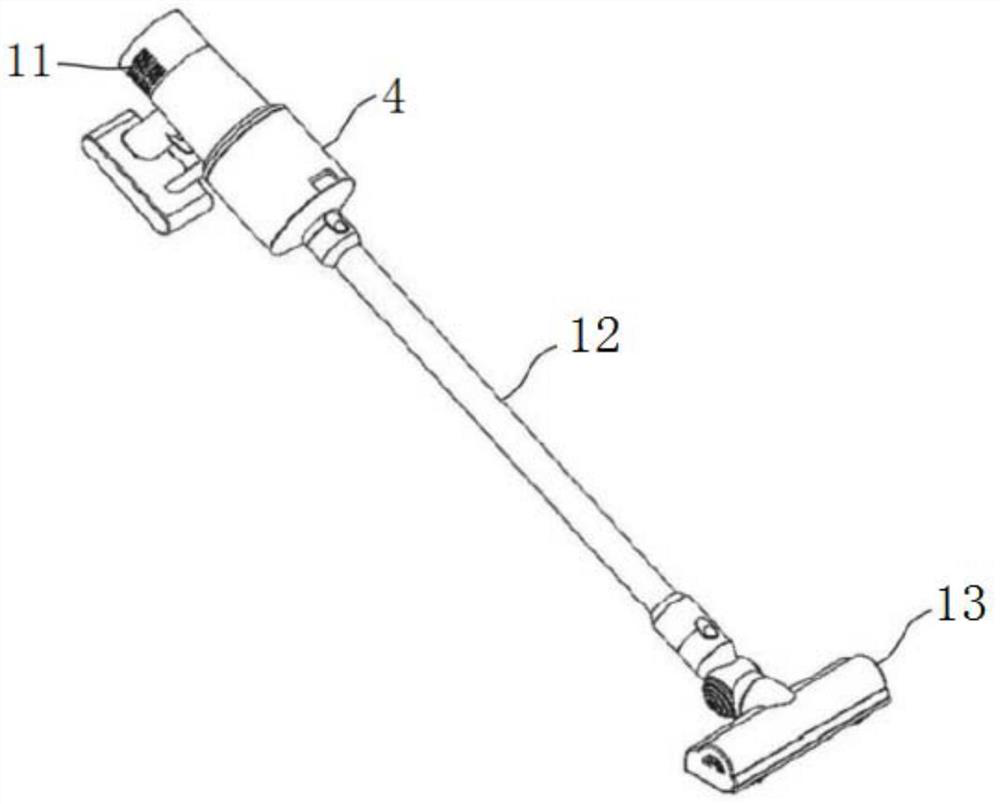

[0070] This embodiment provides a vacuum cleaner, such as figure 1 shown, including:

Embodiment 1

[0071] The dust separation device provided in embodiment 1;

[0072] Dust suction pipe 12, one end of which is connected to the air inlet 5 of the dust separation device;

[0073] The vacuum cleaner head 13 is connected to the other end of the dust suction pipe 12 . The vacuum cleaner head 13 itself will be in contact with the positions that need to be cleaned such as the ground, sofas, and corners. When the dust separation device starts to generate negative pressure, the negative pressure will suck the dust into the dust separation device through the dust suction pipe 12 through the vacuum cleaner head 13, thereby realizing the storage of the dust itself.

[0074] In this example, if figure 1 As shown, a handle can be directly provided on the dust separation device to form a hand-held vacuum cleaner. When the dust collection operation is required, the user can directly hold the handle to realize the dust collection operation.

[0075] As a modification, the dust and dirt s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com