A temperature-controlled self-adaptive dust removal and cooling grinding wheel device for a dry grinder

A grinding wheel device and self-adaptive technology, which can be used in grinding drive devices, grinding/polishing safety devices, and parts of grinding machine tools, etc., which can solve the problems of poor thermal cooling effect of grinding and unsatisfactory abrasive grain extraction effect. , to achieve reliable dust removal effect, improve grinding dust removal effect, and avoid the effect of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

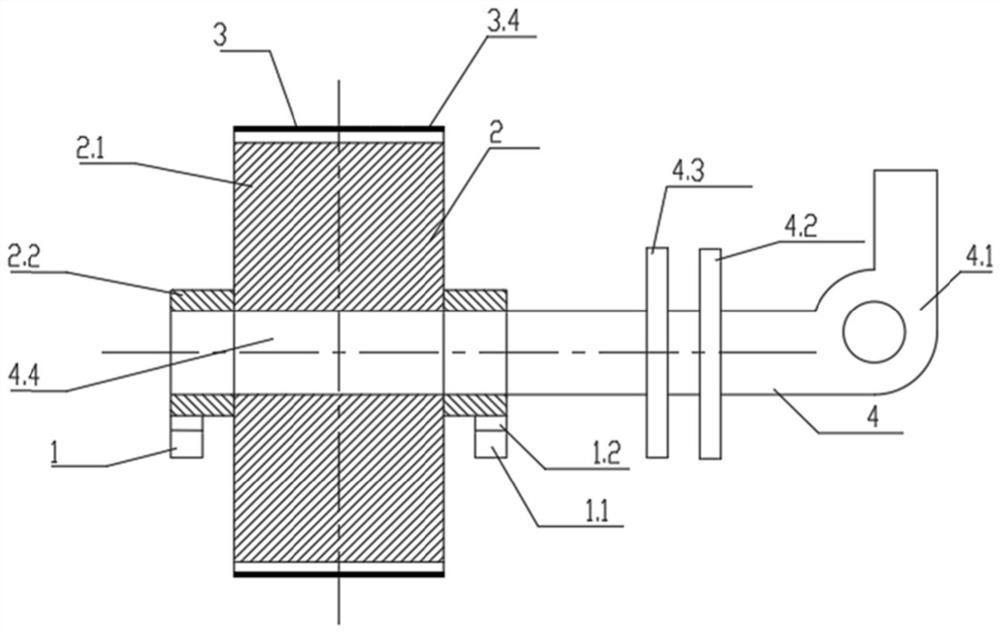

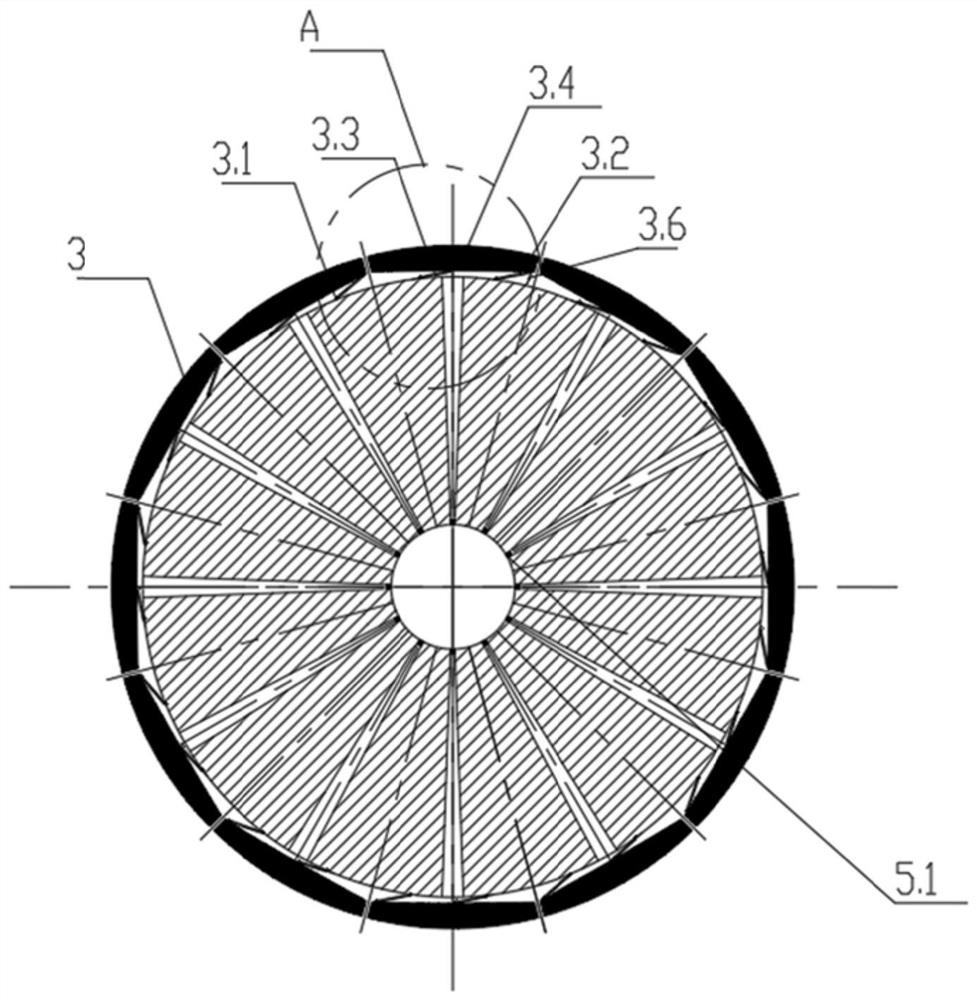

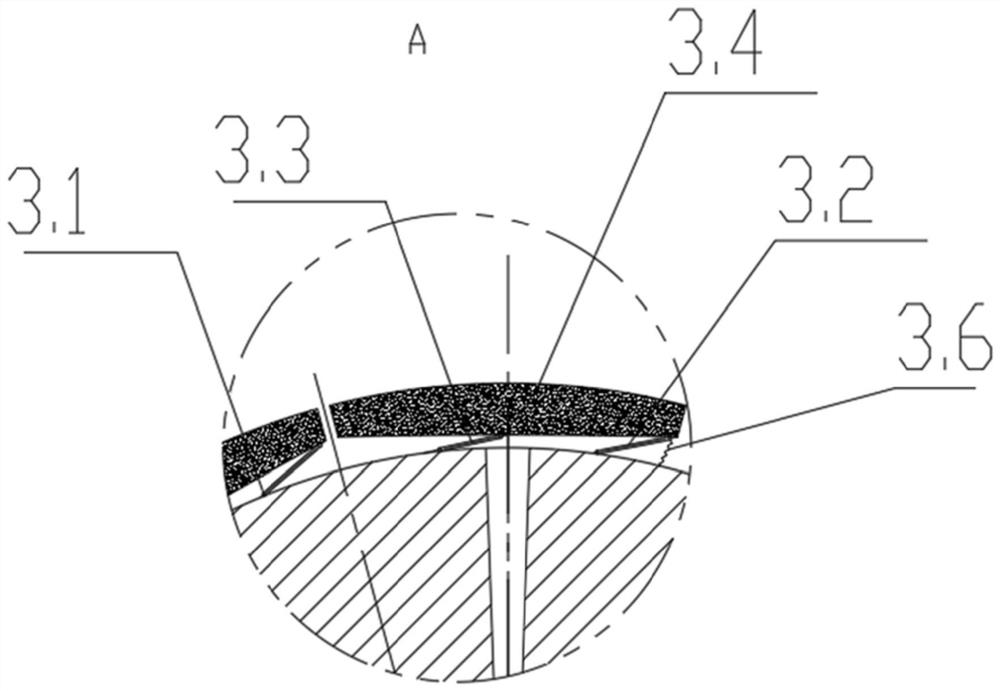

[0020] like figure 1 As shown, this embodiment provides a dry grinding machine temperature control adaptive dust removal and cooling grinding wheel device, including a support 1, a grinding wheel base device 2, a grinding wheel grinding disc system 3, a grinding wheel air duct system 4, and a grinding wheel air duct control system 5 .

[0021] The support 1 consists of a bearing seat 1.1 and a bearing 1.2. The bearing seat 1.2 is fixed on the moving frame of the grinding machine, and moves with the moving frame to realize the overall feed grinding of the grinding wheel device. The bearing 1.2 is placed in the bearing seat 1.1, so as to realize the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com