Mixer truck for building construction

A technology for building construction and mixer trucks, which is applied in construction, building structure, cement mixing devices, etc. It can solve the problems of poor mixing uniformity, low efficiency, and single operation mode, and achieve the effect of improving mixing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

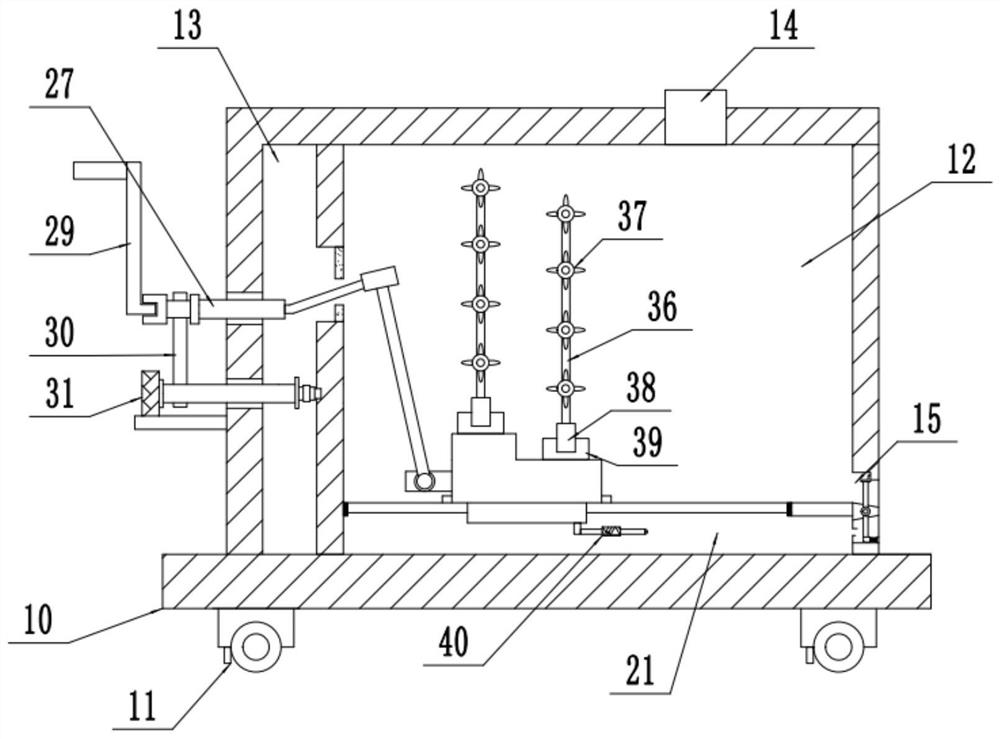

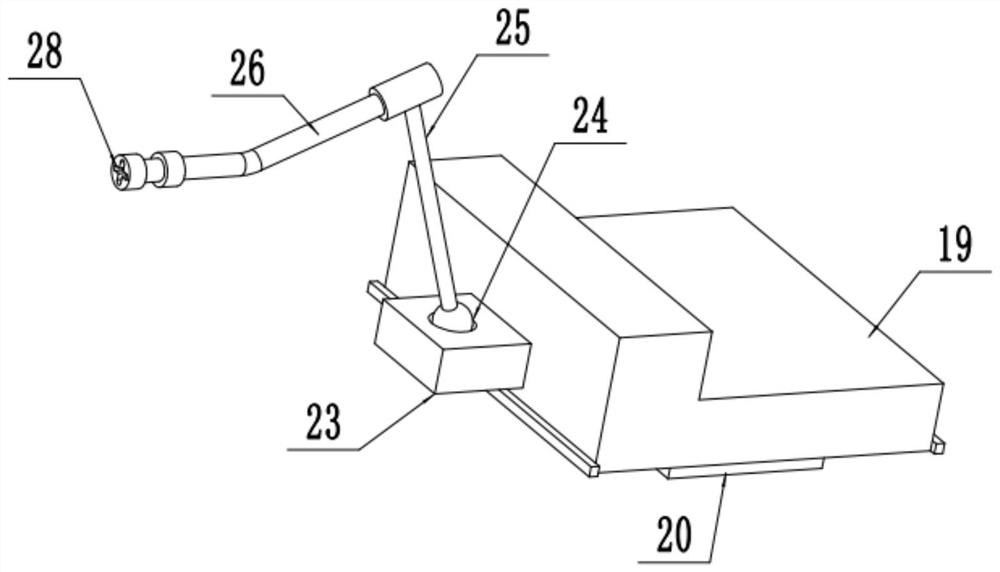

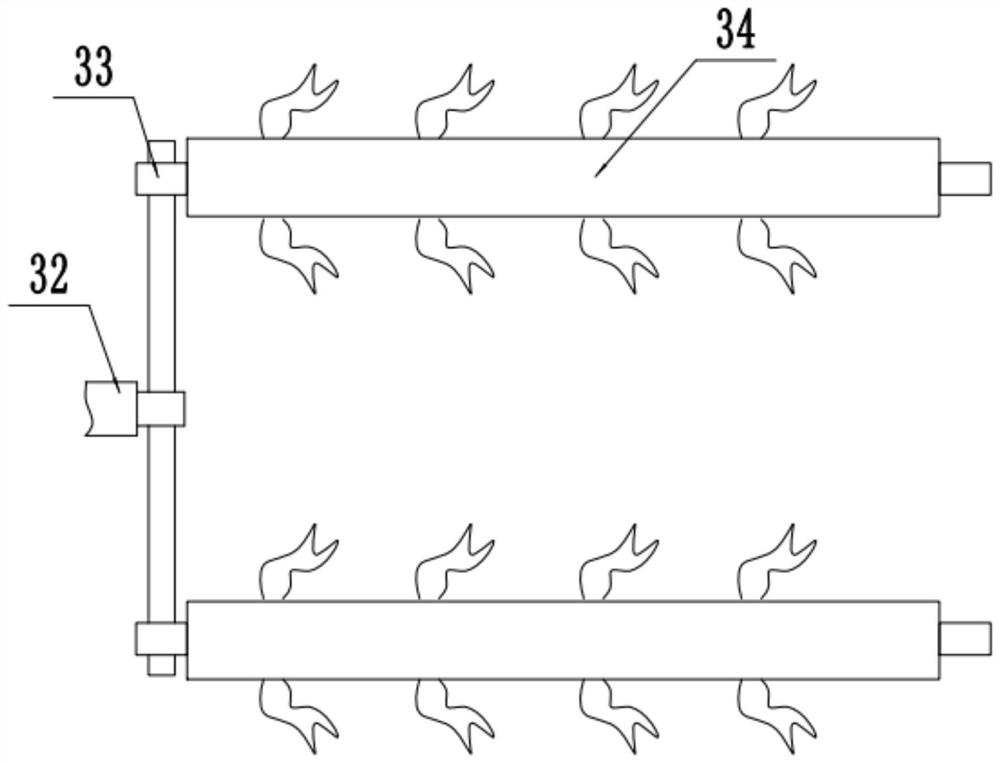

[0019] see Figure 1-3 , a building construction mixer truck, comprising a locomotive base 10, a moving wheel 11, a mixing chamber 12, a feed inlet 14, and a material outlet 15; the four corners of the bottom of the locomotive base 10 are rollingly connected with four groups of moving wheels 11, and the locomotive base The top of 10 is fixedly equipped with a group of stirring chambers 12, the top right side of the stirring chamber 12 is provided with a feed inlet 14, and the lower middle part of the right side wall is provided with a discharge port 15, and the inner left side of the stirring chamber 12 is passed through a vertical partition. The plate is provided with a set of power chambers 13 . The inner lower side of the locomotive base 10 is provided with a group of cavities 21 through a group of transverse partitions, and a transverse chute is provided in the middle of the transverse partition, and a group of sliders 20 are fixedly installed inside the chute. The top of...

Embodiment 2

[0022] refer to figure 1 , 4, on the basis of Embodiment 1, a set of vertical swing baffles 16 is rotatably connected to the inner middle of the discharge port 15, and a set of vertical swing baffles 16 is fixedly installed on the top of the swing baffle 16 to prevent the top of the swing baffle 16 from moving outwards. Limiting block 17, the right side of the bottom of the swing baffle 16 is elastically connected to the lower part of the inner right side wall of the discharge port 15 through a set of springs 18, and a set of left ends are arranged in the cavity 21 at the height of the middle part of the lower plate of the swing baffle 16. The electric telescopic rod 40 fixed on the bottom of the slider 20, the electric telescopic rod 40 moves left and right following the moving block 19, when it moves to the swing baffle 16, it can push the bottom of the swing baffle 16 to move to the right, and then swing the baffle The upper side of 16 moves outwards, and then opens the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com