A kind of halogen-free flame-retardant antistatic nylon 6 and its preparation method and preparation reaction kettle

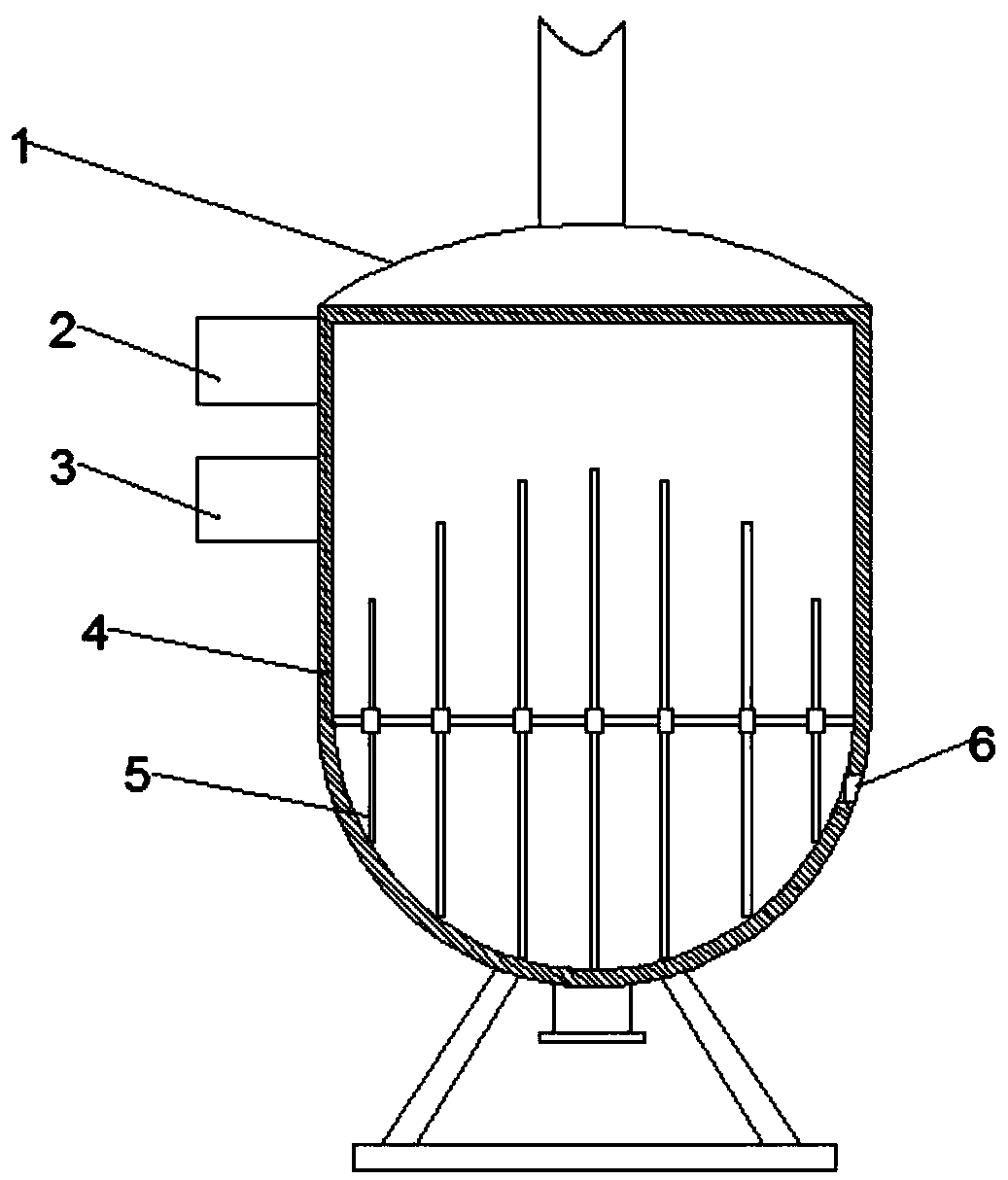

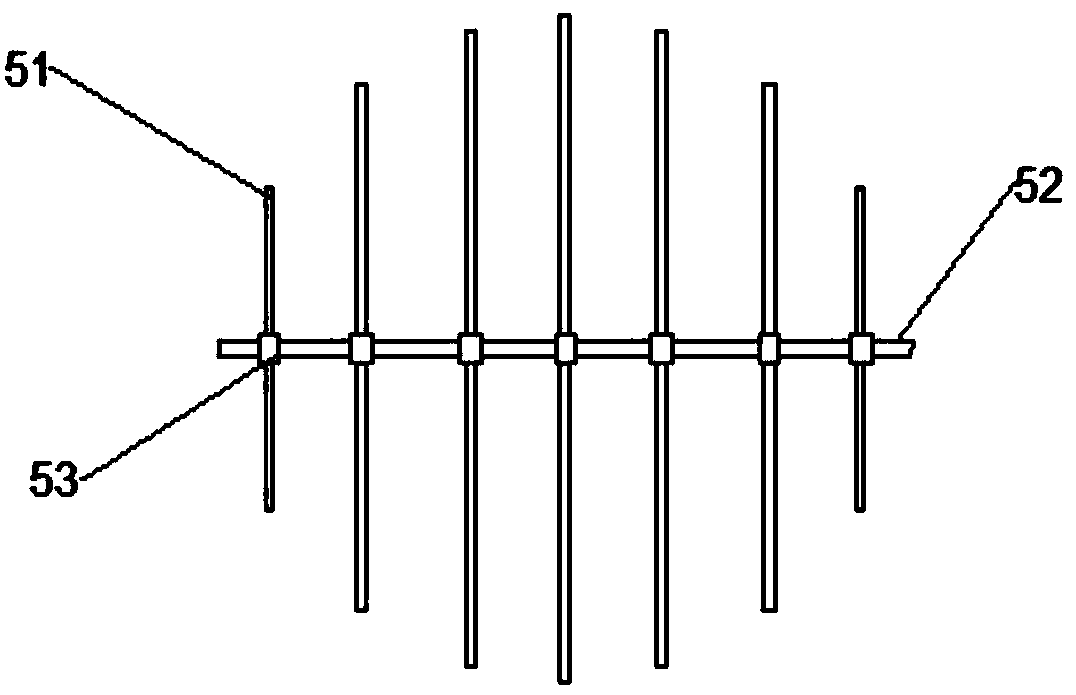

A technology of flame retardant and antistatic reaction kettle, which is applied in the field of preparation, halogen-free flame retardant and antistatic nylon 6, and the field of reaction kettle for preparation, which can solve the problems that the reactants cannot be fully mixed and the stirring area of the reaction kettle stirrer is small, etc. Achieve the effects of avoiding uneven heating, improving stirring precision and avoiding limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The weight components of a halogen-free flame-retardant antistatic nylon 6 chip are:

[0050]

[0051]

[0052] The organophosphorous flame retardant is phosphite;

[0053] The composite antistatic agent is polyether ester amide and polyethylene oxide; the polyether ester amide:polyethylene oxide=1:2.

[0054] The stabilizer is a hindered amine stabilizer.

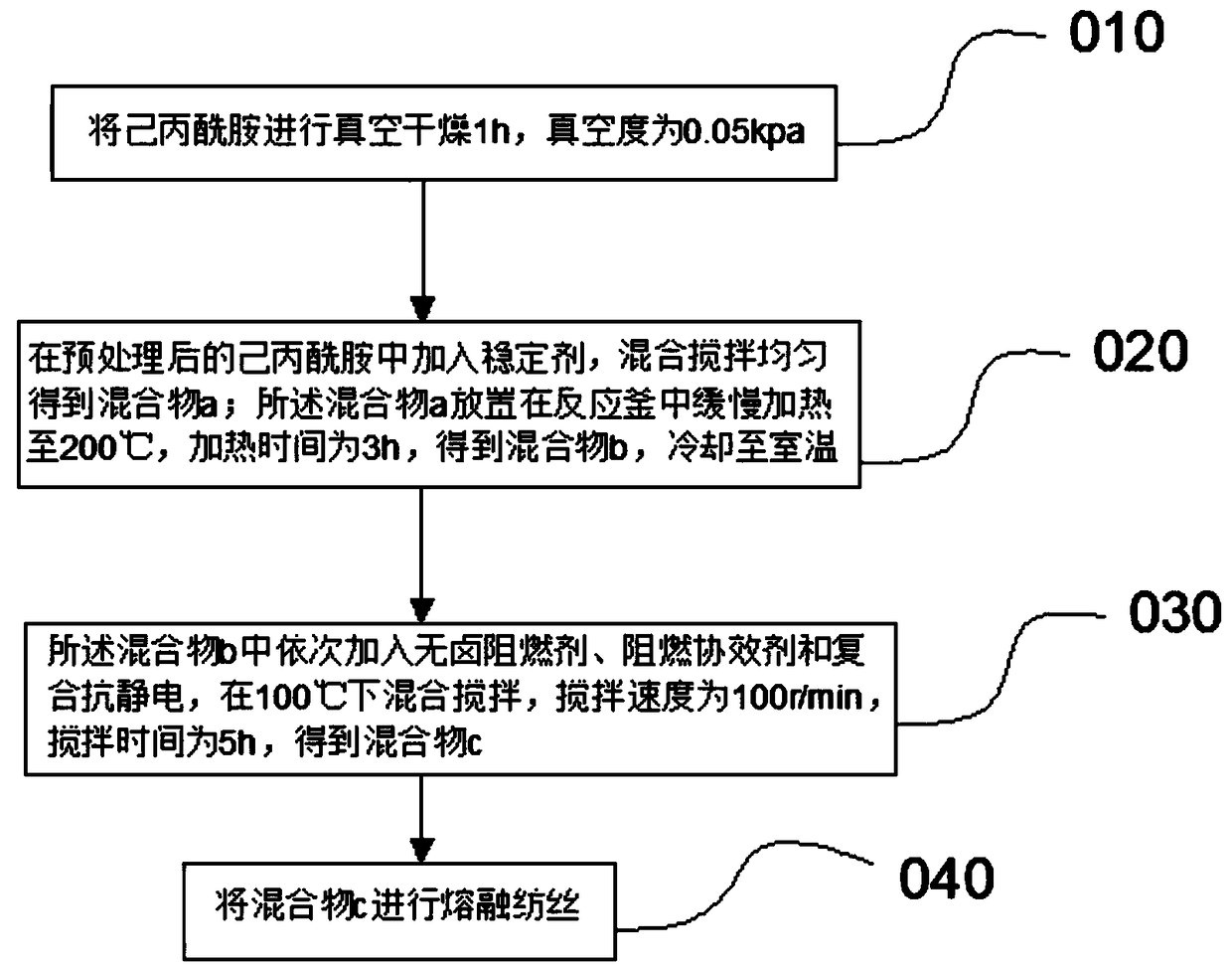

[0055] The preparation method of the halogen-free flame-retardant antistatic nylon 6 chip, such as figure 1 Said: The steps are as follows:

[0056] Step 010, pretreatment of hexapropionamide: vacuum-dry hexapropionamide for 1 hour, and the vacuum degree is 0.05kpa;

[0057] Step 020, adding a stabilizer to the pretreated hexapropionamide, mixing and stirring evenly to obtain a mixture a; the mixture a is placed in a reaction kettle for microwave heating, and the heating temperature is slowly heated to 200° C. for 3 hours to obtain Mixture b is cooled to room temperature; the mixture a can be heated evenly...

Embodiment 2

[0069] The difference between this embodiment and the first embodiment is that the organophosphorus flame retardant is phosphite and organophosphorus salt;

[0070] The composite antistatic agent is polyether ester amide and polyethylene oxide; the polyether ester amide:polyethylene oxide=1:3.

[0071] The stabilizer is a hypophosphite stabilizer.

Embodiment 3

[0073] The difference between this embodiment and the first and second embodiments is that the organophosphorus flame retardant is phosphite, organophosphorus salt and polymer phosphate;

[0074] The composite antistatic agent is an antistatic agent: polyether ester amide and polyethylene oxide; the polyether ester amide: polyethylene oxide = 1.5:2.

[0075] The stabilizers are hindered amine stabilizers and hypophosphite stabilizers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com