Method of rerolling rolled-up material web and rerolling device

A material web, rewinding technology, applied in the field of rewinding device, elastic material winding material web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

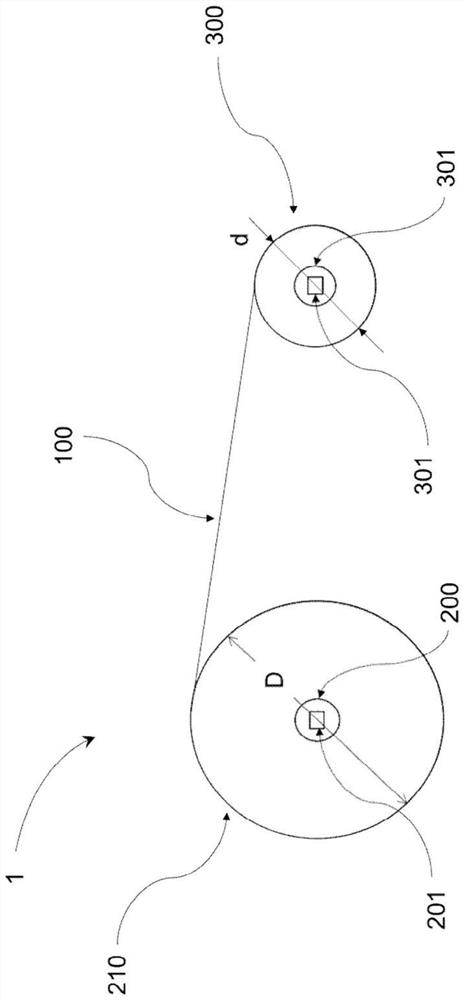

[0048] figure 1 is a schematic side view of the rewinding device 1 according to the invention. The material web 100 wound on the uncoiler 200 on a jumbo roll 210 with a diameter D is rewound by the jumbo roll 210 onto a sub-coil 301 which has a diameter d and is arranged on the coiler 300 .

[0049] The uncoiler 200 and the coiler 300 each have an actuator 201 , 301 by means of which the coil 200 , 300 can be driven and decelerated. During rewinding, the diameter D of the jumbo coil 210 on the uncoiler 200 and the diameter d of the partial coil 301 on the coiler 300 are continuously determined, and using these determined parameters, the actuators 201, 301 are continuously adjusted performance.

[0050] The embodiments shown here are given by way of example only and therefore should not be construed as limiting. Alternative embodiments considered by those skilled in the art are also covered by the scope of protection of the present invention.

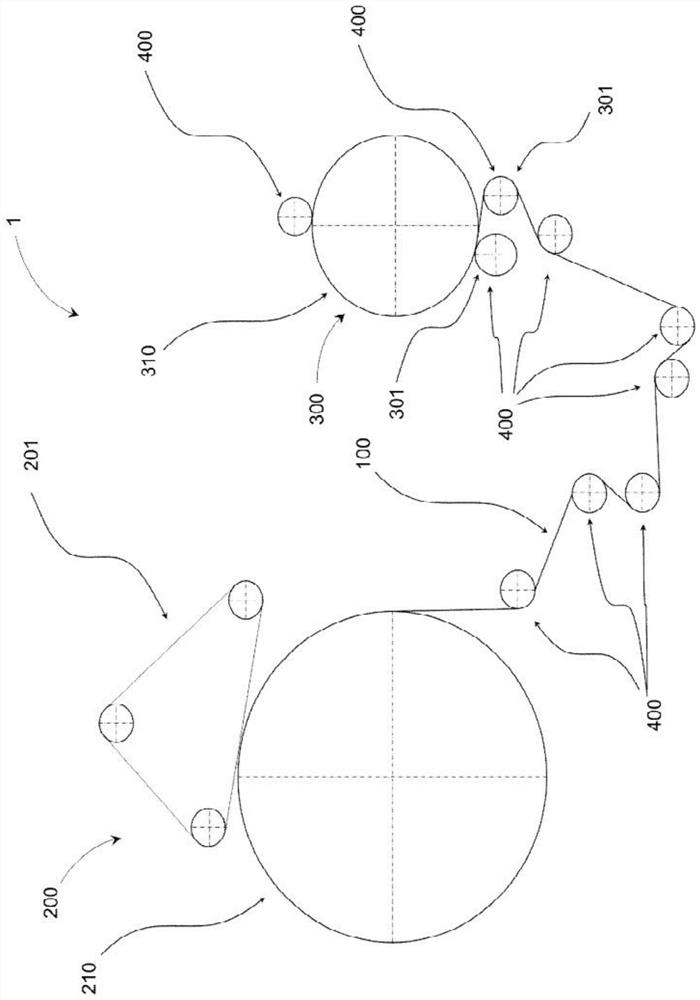

[0051] figure 2 is a schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com