Production process method of ultrahigh-strength TA4 titanium alloy thin strip

A titanium alloy thin, ultra-high-strength technology, applied in the field of metallurgy, can solve the problems that the strength elongation does not decrease, cannot improve the strength index of TA4/Grade4 titanium alloy thin strips, and cannot guarantee elongation, etc. The effect of improved properties, increased tensile and yield strength, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the first embodiment of the present invention in conjunction with the description of the technical solution clearly and completely. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

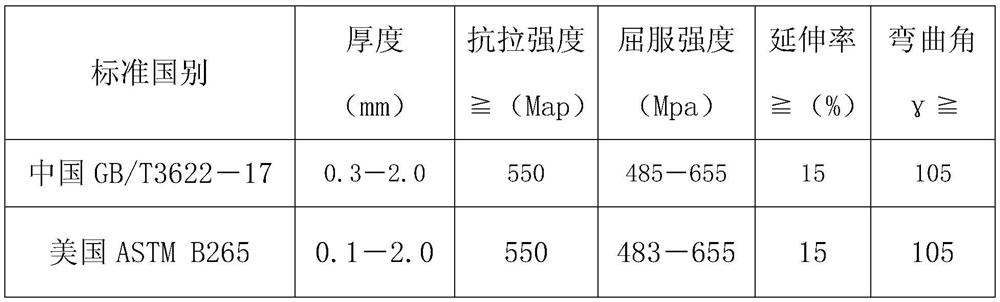

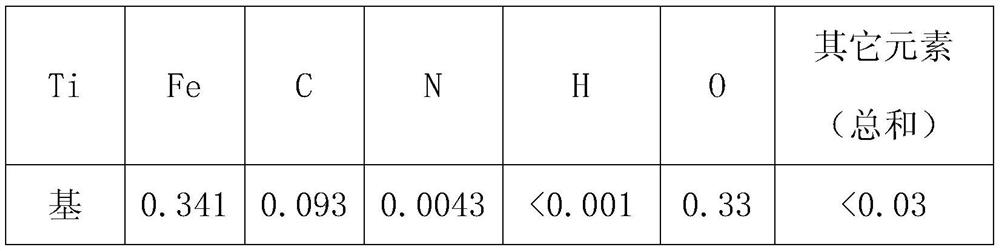

[0024] The production process method of ultra-high-strength TA4 titanium alloy thin strip is characterized in that: after the TA4 titanium alloy strip is treated with a multi-rolling method formed by repeated cold rolling with step deformation and multiple online continuous solution step annealing alternately, the obtained Tensile strength ≧ 700Mpa, yield strength ≧ 600Mpa, elongation ≧ 15% TA4 titanium alloy thin strip, the TA4 titanium alloy strip blank of 1.2 × 530 × L (TA4 titanium alloy strip length) mm is rolled to a thickness of 0.15mm TA4 titanium alloy strip, wherein the chemical composition of the 1.2×530×Lmm TA4 titanium alloy strip blank is as follows:

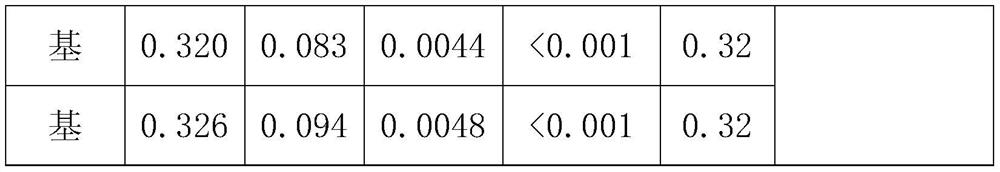

[0025]

[0026]

[0027] The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com