An auxiliary equipment for bolt connection in the construction of a steel structure building

A technology of auxiliary equipment and house building, applied in the direction of building structure, construction, and building materials processing, etc., can solve the problems of low work efficiency, labor-intensive, cumbersome operation process, etc., and achieve improved work efficiency, simple manual operation, saving human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

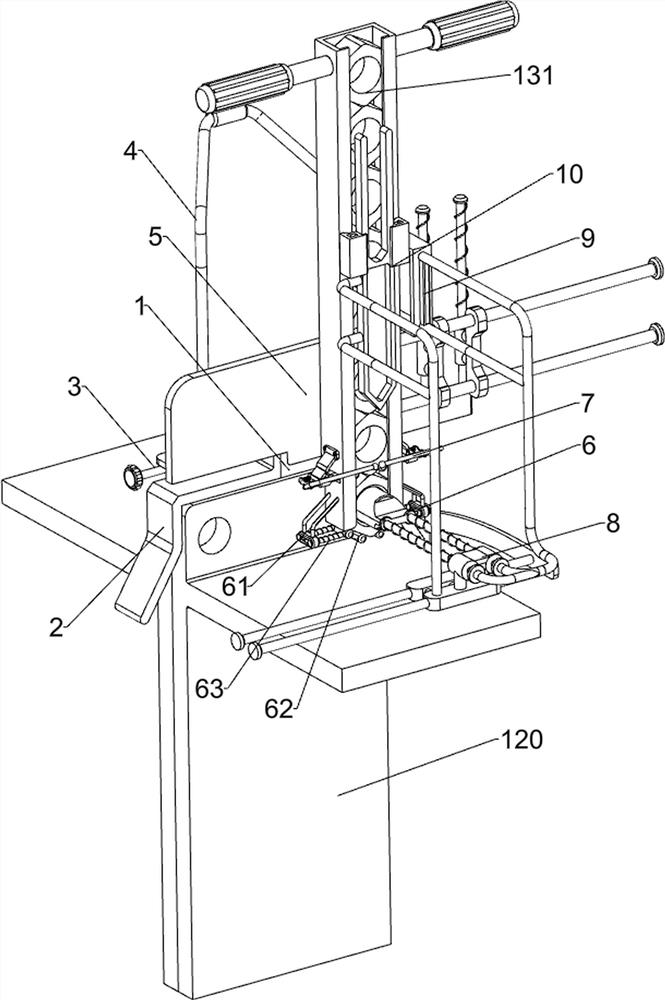

[0027] A kind of bolt connection auxiliary equipment for steel structure building construction, such as Figure 1-4 As shown, it includes a first extruding frame 1, a second extruding frame 2, a screw rod 3 and a first handle 4, and the first extruding frame 1 is slidably connected with a second extruding frame 2, and the first extruding frame 1 The screw rod 3 is connected to the upper rotation, and the screw rod 3 is threadedly matched with the second extrusion frame 2. The first handle 4 is connected to the top of the first extrusion frame 1. It also includes a moving assembly 5, a limit assembly 6 and a material blocking assembly 7. The first extrusion frame 1 is provided with a moving assembly 5 , and the moving assembly 5 is provided with a limiting assembly 6 and a material blocking assembly 7 .

[0028] The moving assembly 5 includes a fixed plate 51, a first sliding sleeve 52, a slide bar 53, a connecting frame 54 and a second handle 55, the first extruding frame 1 is...

Embodiment 2

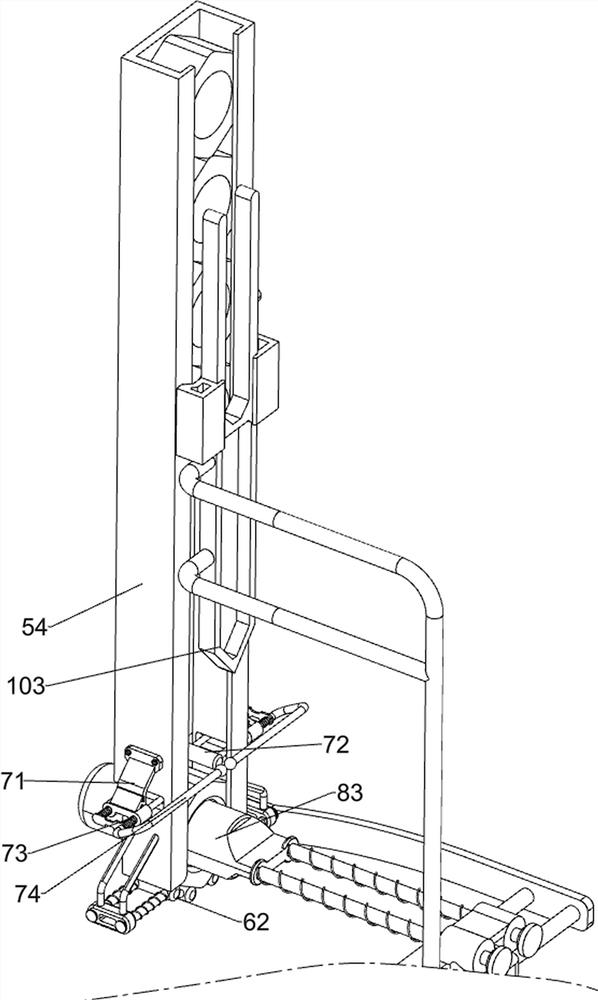

[0033] On the basis of Example 1, such as image 3 As shown, a positioning assembly 8 is also included. The positioning assembly 8 includes a guide rail 81, a second sliding sleeve 82, a positioning rod 83 and a return spring 84. The right side of the first extrusion frame 1 is connected with a guide rail 81, and the left side of the guide rail 81 is A second sliding sleeve 82 is slidably connected to the side, and a positioning rod 83 is slidably connected to the second sliding sleeve 82 , and a return spring 84 is connected between the positioning rod 83 and the second sliding sleeve 82 .

[0034]When operating the first extrusion frame 1 and the second extrusion frame 2 to clamp the steel frame 120, it is necessary to pull the positioning rod 83 to move forward, and the return spring 84 is compressed. After clamping, pull the positioning rod 83 to align The holes corresponding to each other of the two steel frames 120, if the two holes are completely corresponding, the posi...

Embodiment 3

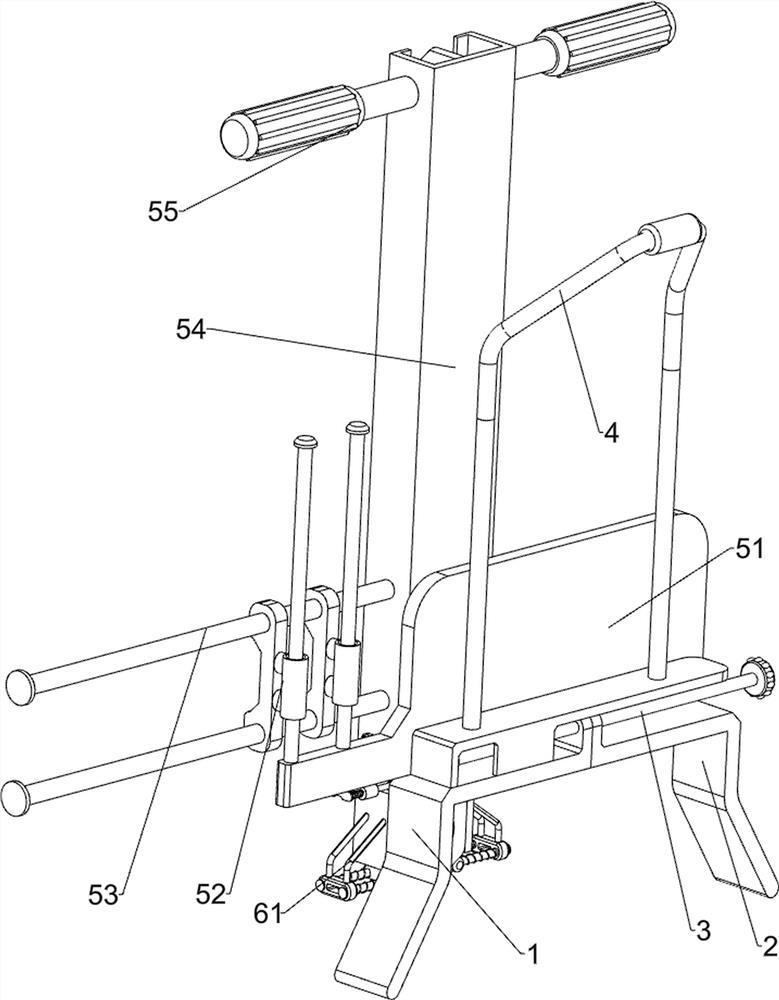

[0036] On the basis of Example 2, such as image 3 As shown, it also includes a clamping assembly 9, the clamping assembly 9 includes a first connecting rod 91, a limit frame 92 and a second tension spring 93, the front side of the positioning rod 83 is connected with the first connecting rod 91, the first A limiting frame 92 is connected to the connecting rod 91 , and the limiting frame 92 cooperates with the sliding rod 53 , and a second tension spring 93 is connected between the first sliding sleeve 52 and the fixing plate 51 .

[0037] Initially, the second tension spring 93 is in a stretched state, and the limit frame 92 pushes against the slide bar 53. When the positioning rod 83 is pulled to move forward, the positioning rod 83 moves forward to drive the limit through the first connecting rod 91. The frame 92 moves forward, and when the limit frame 92 moves forward until it no longer touches the slide bar 53, the first sliding sleeve 52 moves upward under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com