Advance ratio for single unducted rotor engine

A rotary engine, unducted technology, applied in engine manufacturing, engine components, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

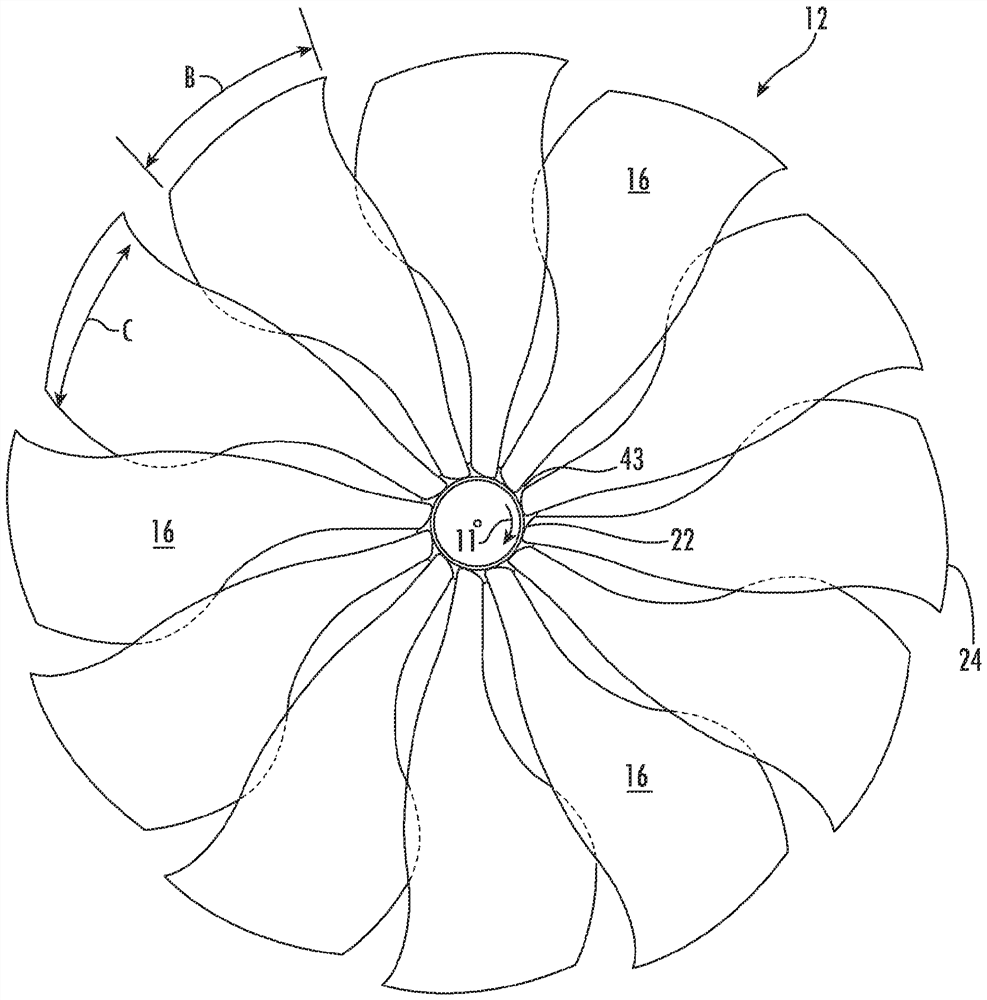

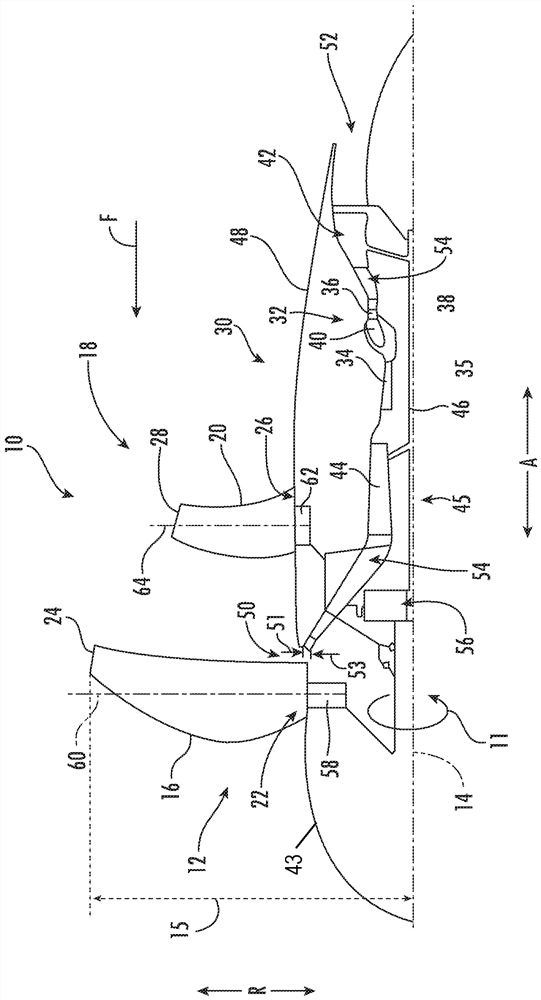

[0085] Example 1: An engine with a stage of unducted rotor blades can define a forward ratio of approximately 3.8 during maximum cruise operating conditions, the engine defines a diameter D equal to 13 feet, approximately 520 miles per hour during maximum cruise operating conditions ("mph"), and an angular velocity of the unducted rotor blades of 930 revolutions per minute ("rpm") during maximum cruise operating conditions.

example 2

[0086] Example 2: An engine with a stage of unducted rotor blades can define a forward ratio of approximately 3.8 during maximum cruise operating conditions, the engine defines a diameter D equal to 13 feet, a flight speed of approximately 520mph during maximum cruise operating conditions , and an angular velocity of the unducted rotor blades of 840 rpm during maximum cruise operating conditions.

example 3

[0087] Example 3: An engine with a stage of unducted rotor blades can define a forward ratio of approximately 5.5 during maximum cruise operating conditions, the engine defines a diameter D equal to 13 feet, a flight speed of approximately 520mph during maximum cruise operating conditions , and an angular velocity of the unducted rotor blades of 642 rpm during the maximum cruise operating condition.

[0088] In each of Example 1, Example 2, and Example 3, the exemplary engine included a stage of unducted rotor blades having a number of rotor blades in the above range, and also included a number of outlet guides in the above range. The stationary outlet of the vane guides the stage of guide vanes. Additionally, in each of Example 1, Example 2, and Example 3, the exemplary engine may be limited to 45 shaft horsepower per square foot ("SHP / ft 2 ”) with 70 SHP / ft 2 between, such as at least 48 SHP / ft 2 , such as at least 50SHP / ft 2 , such as at least 53 SHP / ft 2 , such as at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com