Pilot-operated type breather valve structure and working method

A breathing valve and pilot-operated technology, applied in the direction of control valves, safety valves, balance valves, etc., can solve problems such as gas leakage and response speed block, and achieve the effects of fast response speed, simple structure and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]Embodiments of the present invention will be further described below with reference to the accompanying drawings:

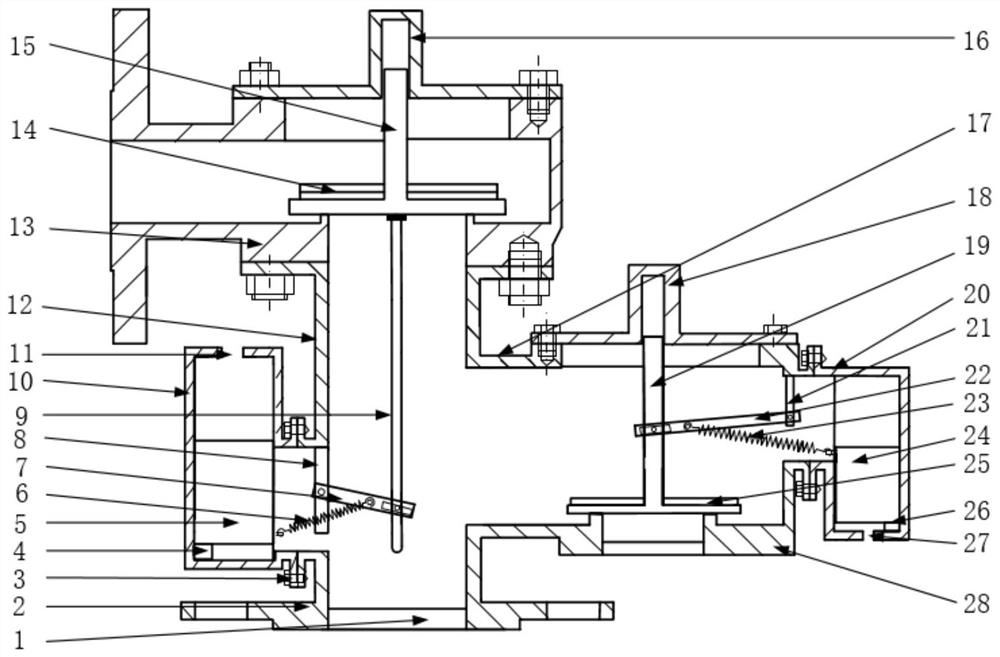

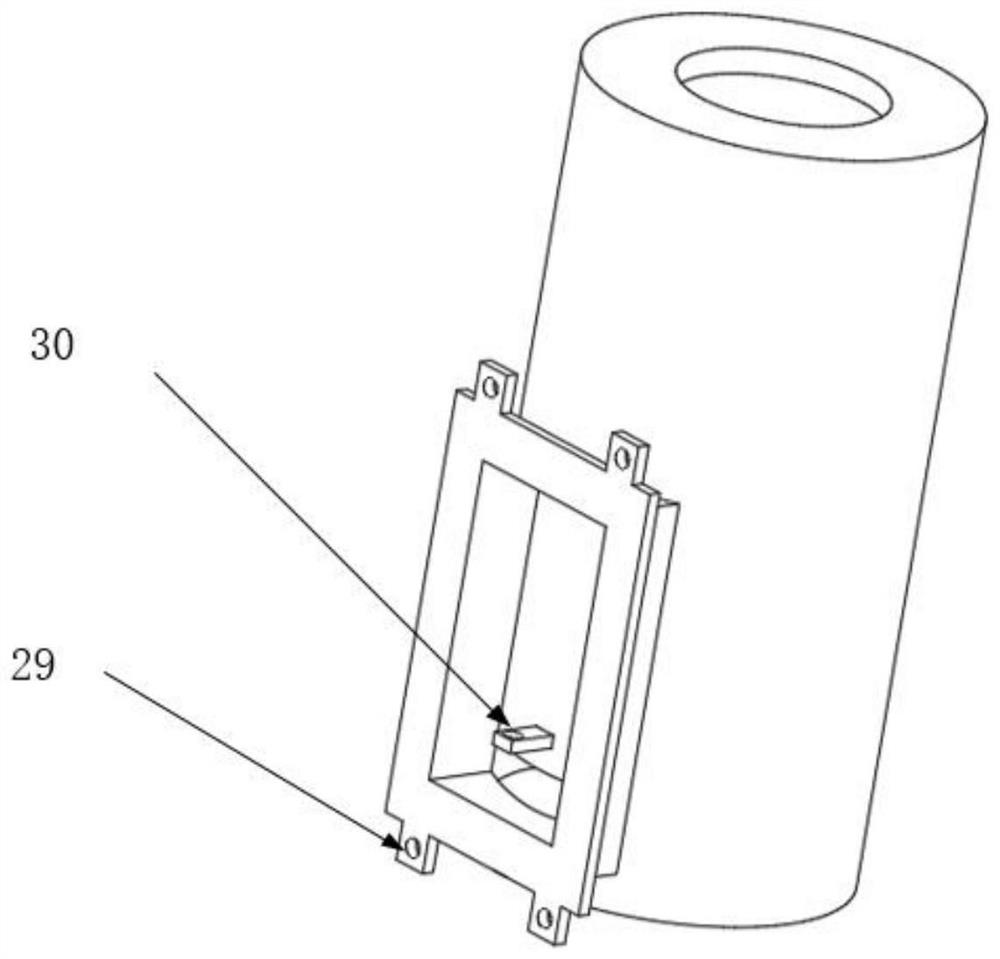

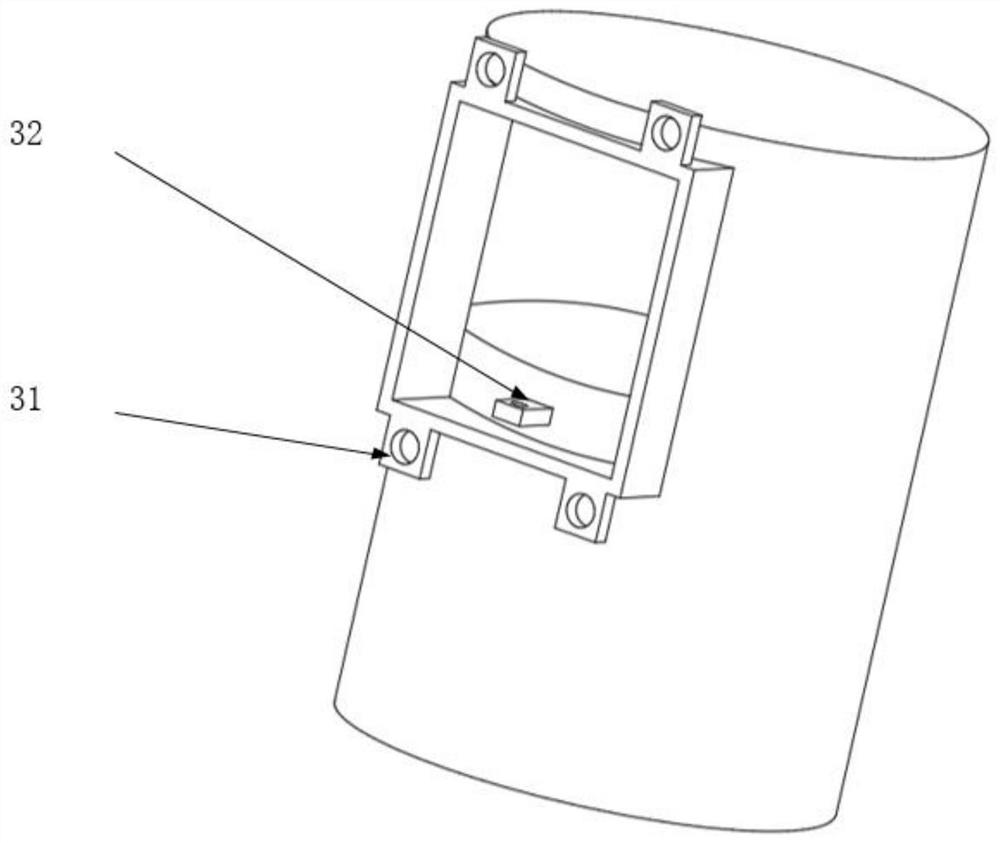

[0046]Such asfigure 1 ,Figure 11 ,Figure 14 withFigure 15As shown, the pilot respiratory valve structure of the present invention includes a valve body 2, and the left opening of the valve body 2 is provided with a ply valve pilot valve body 10, and the right opening taking the valve pilot valve body 20, further comprising a fountain spring. Advanced linkage mechanism and suction valve spring accumulation link mechanism;

[0047]Such asFigure 4 As shown, the valve body 2 includes a fountain valve body 12 and a valve valve body 28, the fountain valve body 12 and the suction valve body 28 are connected by the connecting pipe 17 and the tube valve body 12 and the suction valve body 28 respectively passed The welding is connected to the connecting conduit 17; the tubular valve body 12 and the suction valve body 28 are two upper and lower open tubular structures, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com