High-strength shock absorption and compression resistance type cement pipe column

A cement pipe, high-strength technology, applied in the field of pipelines, can solve the problems of short service life, rupture of cement pipes, damage to the surface of the pipe body, etc., and achieves the effect of good supporting effect, good compressive and seismic resistance, and good supporting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

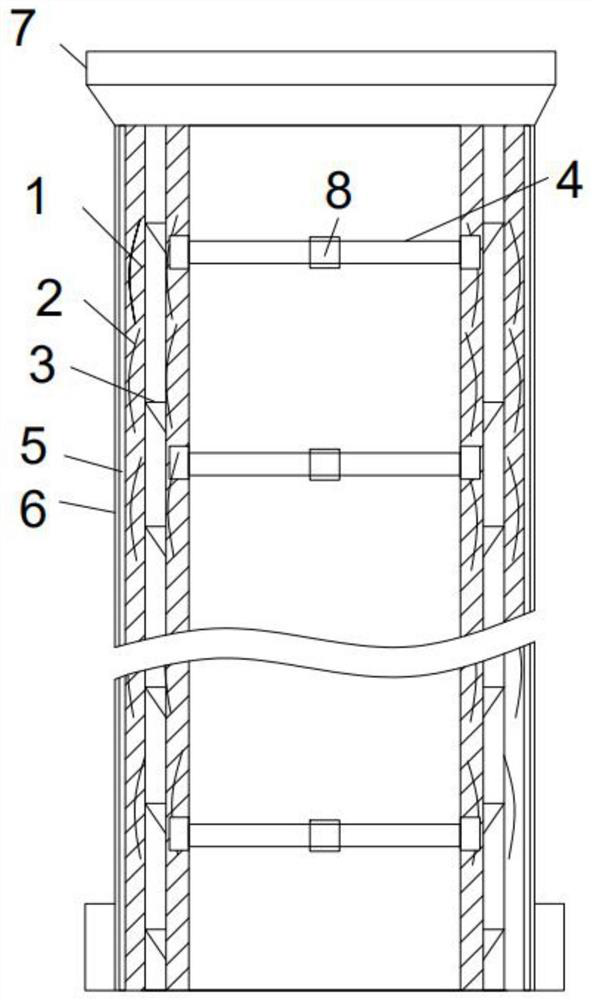

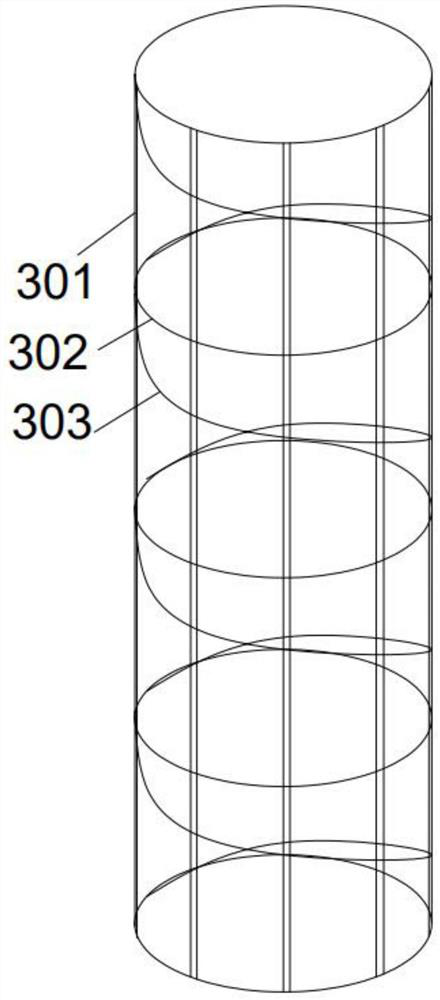

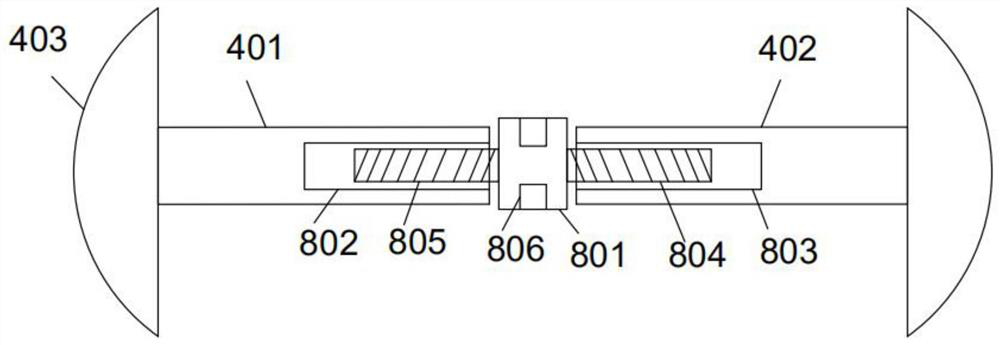

[0029] see Figure 1-Figure 3, a high-strength shock-absorbing and compression-resistant cement pipe column, comprising a concrete base 1, the interior of the concrete base 1 is provided with plant fiber filaments 2, and the inside of the concrete base 1 is pre-planted with a support skeleton 3, and the support The skeleton 3 includes a main planting bar 301, the outer side of the main planting bar 301 is provided with a ring planting bar 302, the outer side of the main planting bar 301 is provided with a spiral planting bar 303, and the inside of the concrete base 1 is provided with a compression mechanism 4. A reinforcement grid layer 5 is provided on the outside of the concrete base layer 1, a coating layer 6 is provided on the outside of the reinforcement grid layer 5, and a connecting mechanism 7 is fixedly connected to both ends of the concrete base layer 1; The pressing mechanism 4 includes a first pole 401, the end of the first pole 401 is fixedly equipped with a teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com