A lobster inactivation, sterilization and cleaning integrated equipment

A technology for inactivating and lobster, applied in shrimp/lobster processing, climate change adaptation, food processing, etc., can solve problems such as waste of energy, low sterilization efficiency, and low steam utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

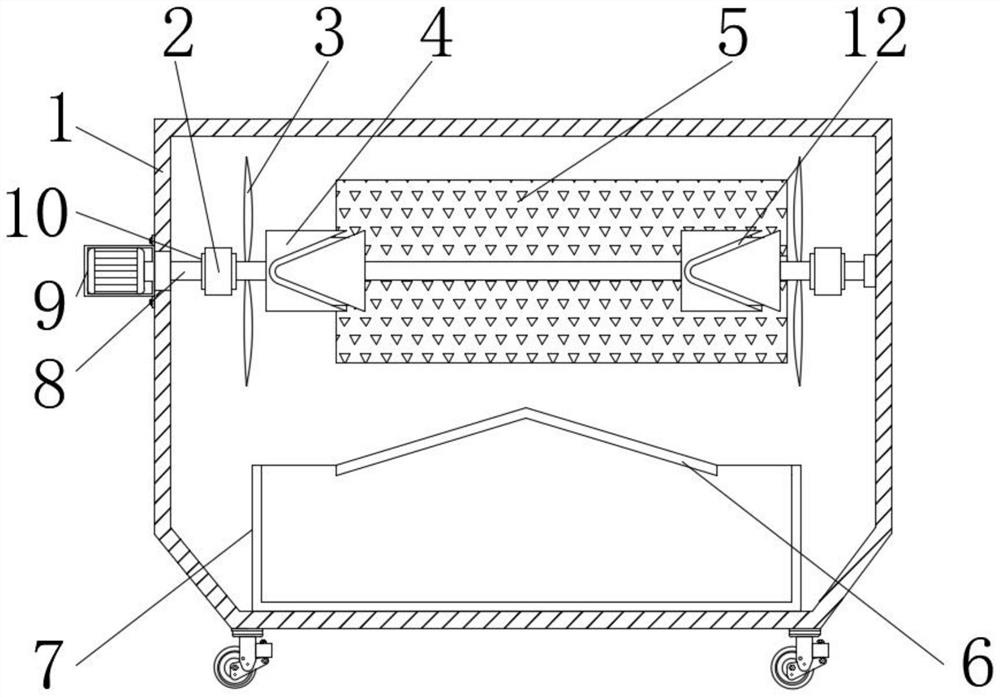

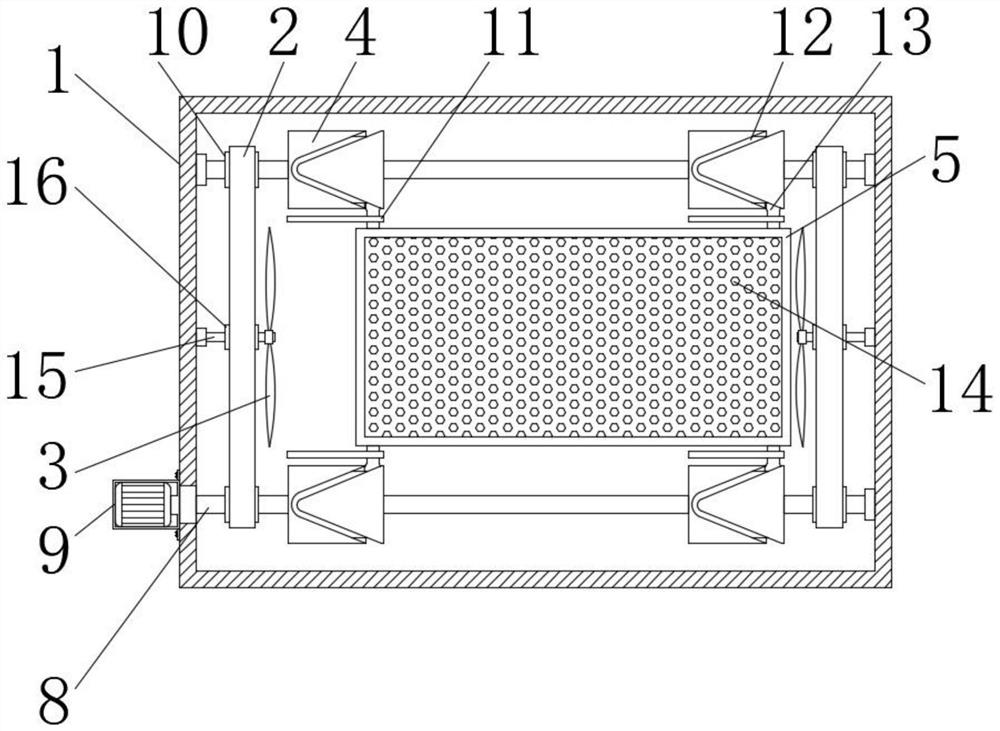

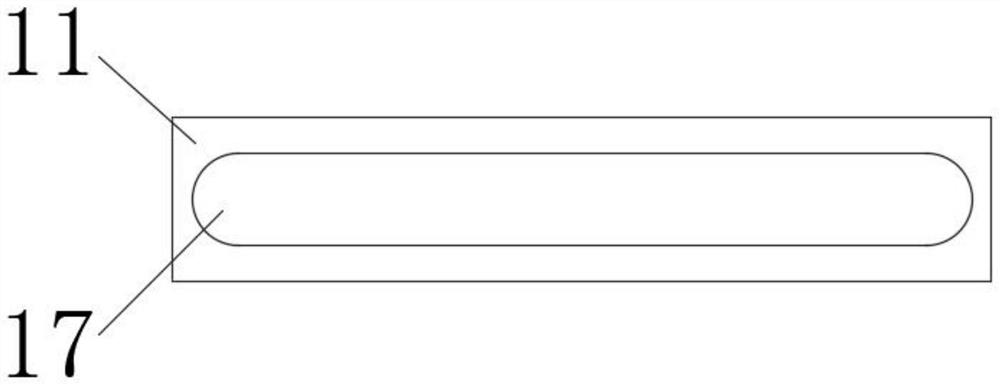

[0026] like Figure 1-3 As shown, the embodiment of the present invention provides an integrated equipment for lobster inactivation, sterilization and cleaning, including a work box 1, a sterilization and cleaning box 5, a steam box 7 and a servo motor 9, and two transmission rods 8 are arranged inside the work box 1 , the two transmission rods 8 are respectively located on the front and rear sides of the sterilization and cleaning box 5, and the outer surfaces of the two transmission rods 8 and the positions close to both ends are fixedly sleeved with a driving adjustment cylinder 4, and the outer surfaces of the plurality of driving adjustment cylinders 4 are fixedly sleeved. The driving grooves 12 are all provided with the driving grooves 12, and the driving grooves 12 are distributed around the outer surface of the driving adjusting cylinder 4. The interiors of the plurality of driving grooves 12 are all slidably clamped with adjusting rods 13, and one end of the plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com