High-strength steel roll forming arc position online punching device

A roll forming and punching device technology, which is applied in the field of punching dies, can solve problems such as square hole deformation, and achieve the effects of overcoming deformation, simple structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

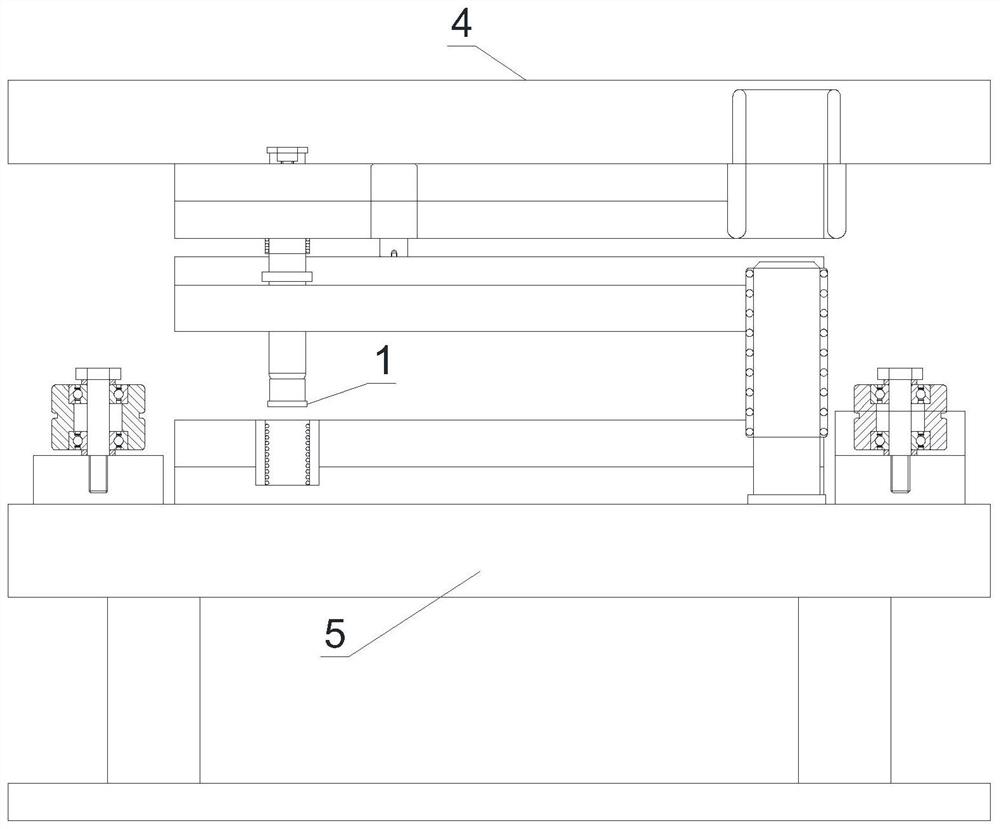

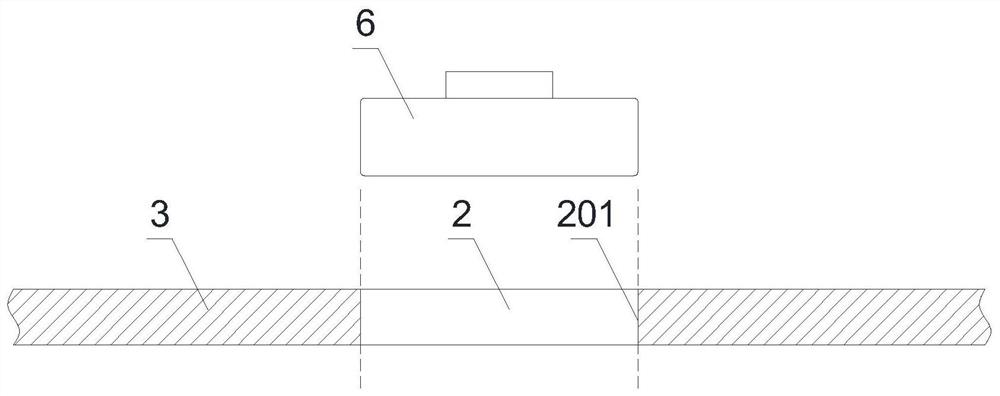

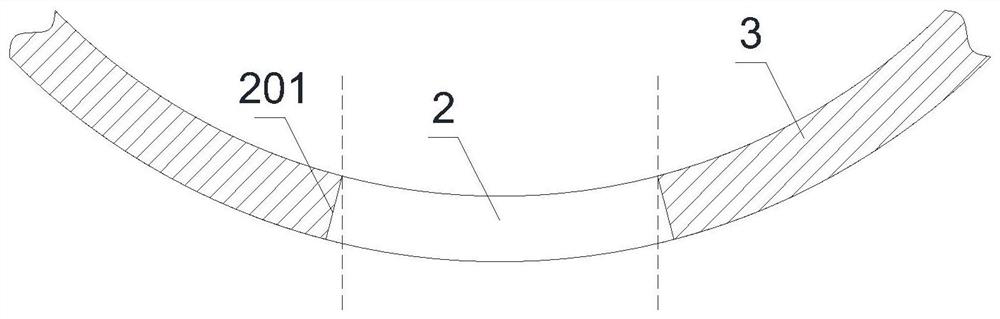

[0023] Such as Figure 1-Figure 7 As shown, on the existing online punching device for high-strength steel roll forming, the original square punch 6 is replaced by the punch 1 with a slope on the long side 201 .

[0024] A high-strength steel roll forming arc position online punching device, including an upper die assembly 4 for downward punching, and a lower die assembly 5 cooperating with the upper die assembly 4, the upper die assembly 4 includes Compared with the punch 1 for punching the square hole 2, the new punch 1 includes a top surface 101 for installation, a bottom surface 102 for punching, and symmetrically arranged on both sides of the punch 1 corresponding to the long side 201 of the square hole 2 The long-side punching surface 103 of the punch 1 is symmetrically arranged on the short-side punching surface 104 corresponding to the short side 202 of the square hole 2 at both ends of the punch 1;

[0025] The long-side punching surfaces 103 on both sides of the pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com