Discharging mechanism of horizontal metal filing briquetting machine

A technology of discharging mechanism and metal shavings, applied in the direction of presses, manufacturing tools, etc., can solve problems such as easy to smash and hurt people, no way to discharge packages, uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

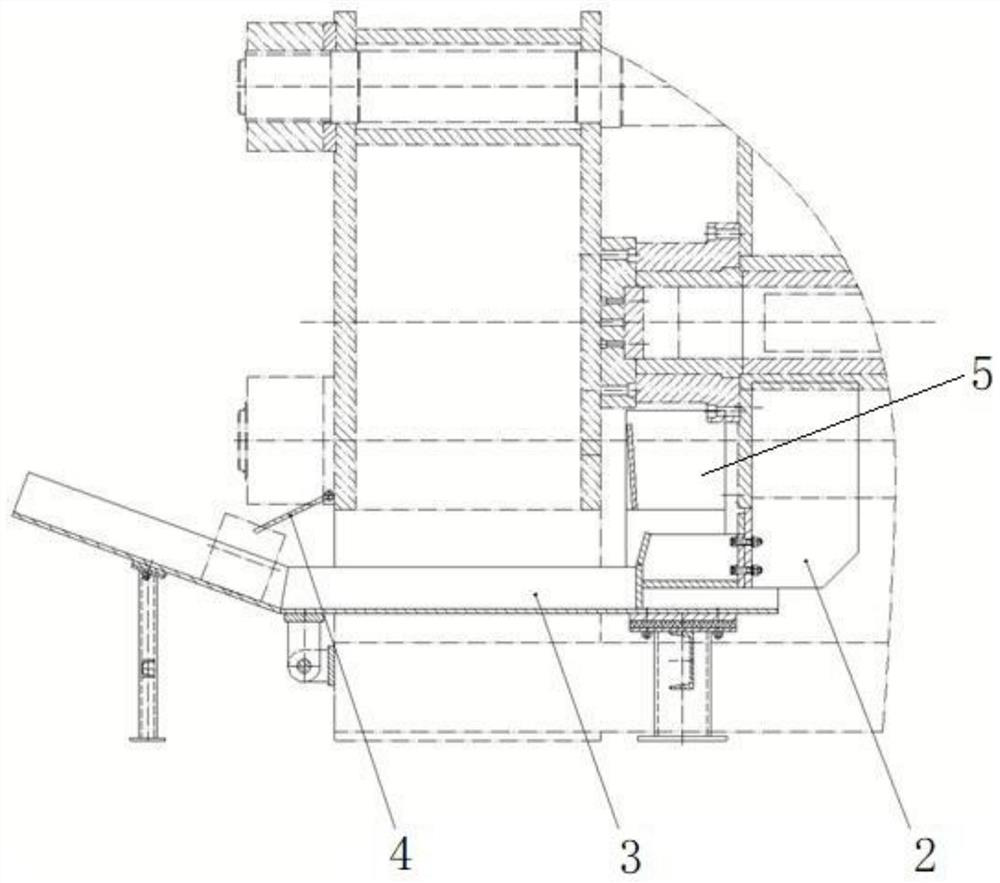

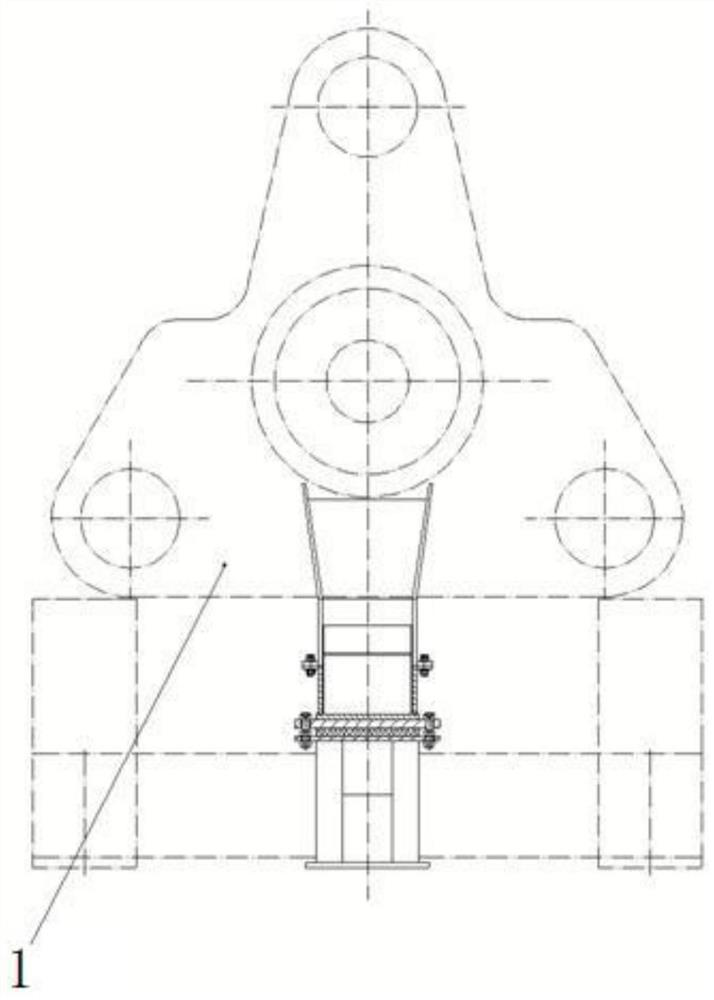

[0034] Such as figure 1 , 2 As shown, a discharge mechanism of a horizontal metal shavings briquetting machine includes a pusher 2 , a discharge chute 3 and a receiving hopper 5 .

[0035] The discharge chute 3 is located in the middle and lower part of the horizontal metal shavings briquetting machine, and side baffles are arranged on both sides of the discharge trough 3 . One end of the discharge trough 3 is the material receiving end, the other end of the discharge chute 3 is the discharge end, the material receiving end is located directly below the discharge port of the horizontal metal chip briquetting machine, and the discharge end extends to the horizontal metal chip briquetting machine machine outside.

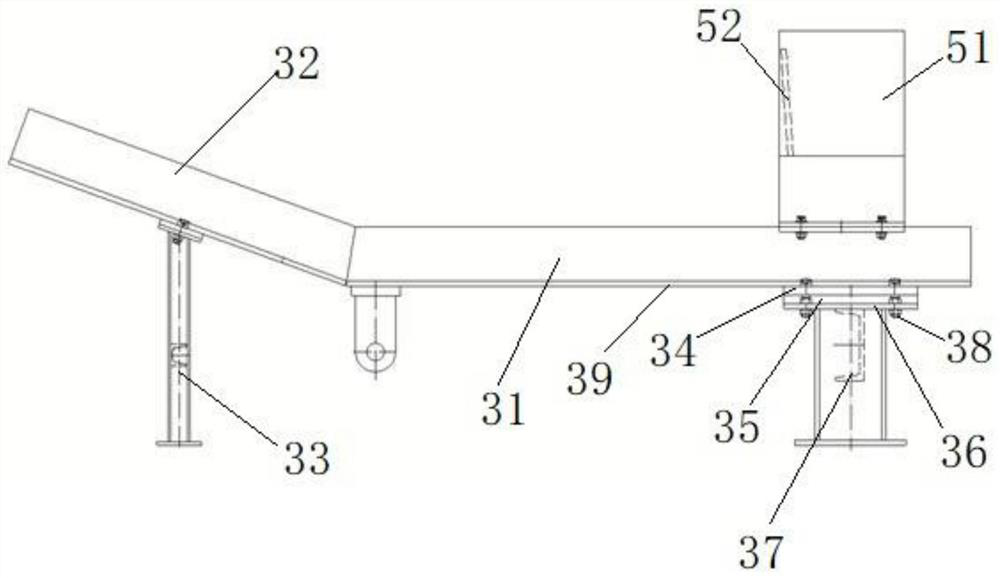

[0036] Specifically, such as image 3 , 4 As shown, the discharge chute 3 includes a horizontal discharge chute 31 , an inclined discharge chute 32 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com