Transportation goods shelf for vehicle assembly parts

A technology of assembly parts and shelves, which is applied in the field of transportation of auto parts, can solve problems such as low strength, damage, and damaged products, and achieve the effect of easy recycling and storage, and reduced space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

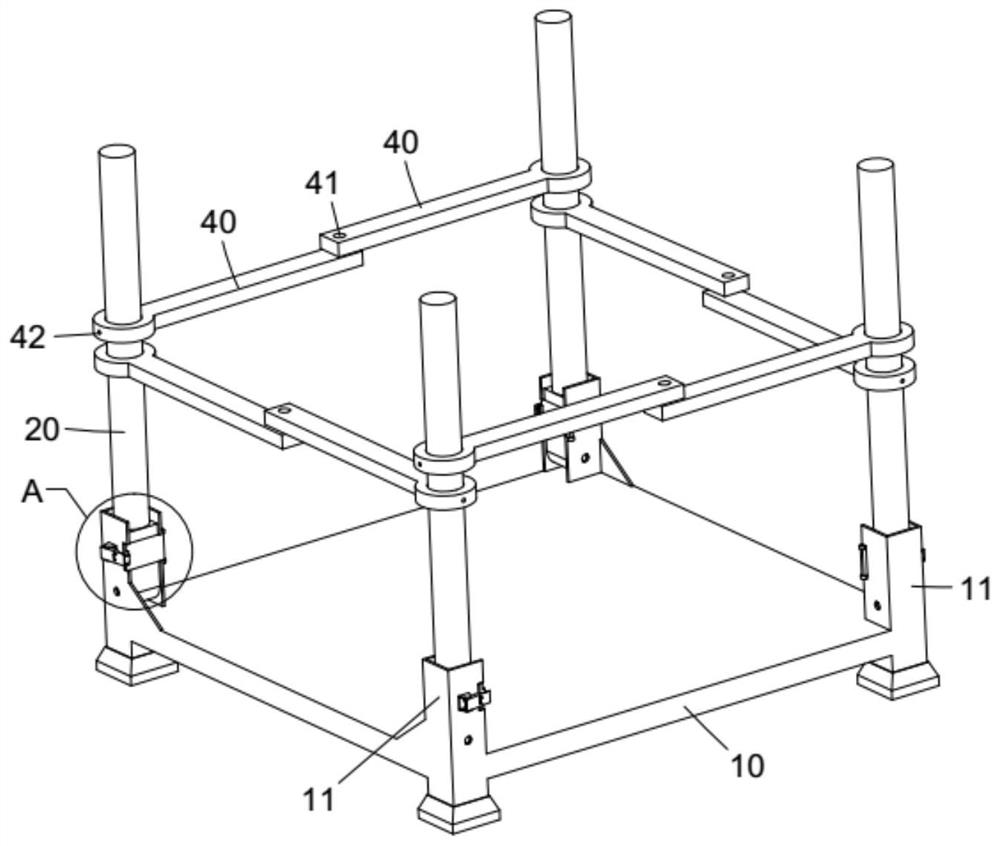

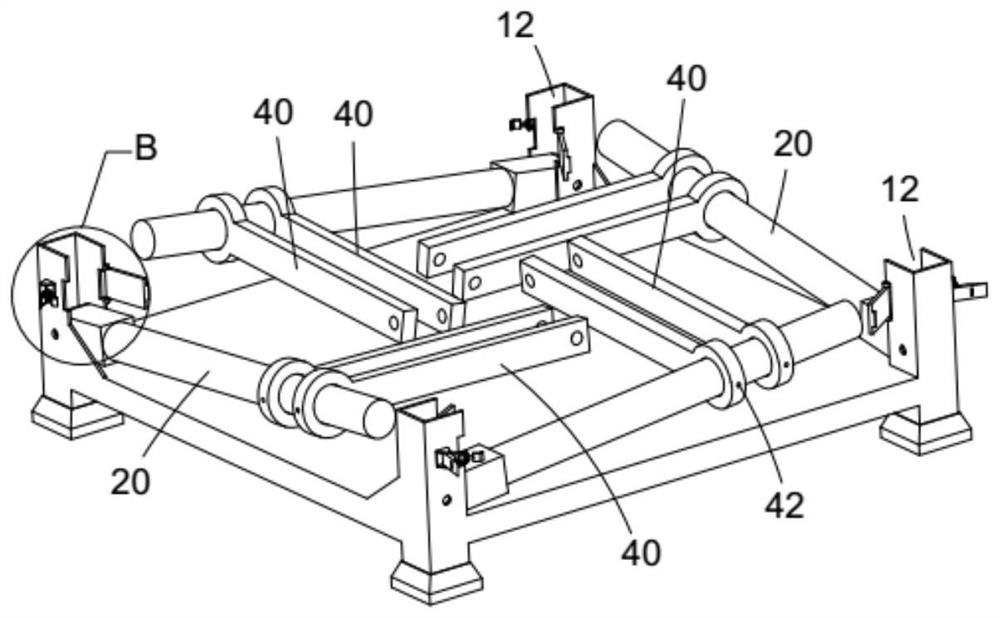

[0025] combine figure 1 , figure 2 , a transport shelf for vehicle assemblies, comprising a square base 10, four uprights 20 and a plurality of struts 40, the four uprights are located at the four corners of the base, and the struts are supported between two adjacent uprights.

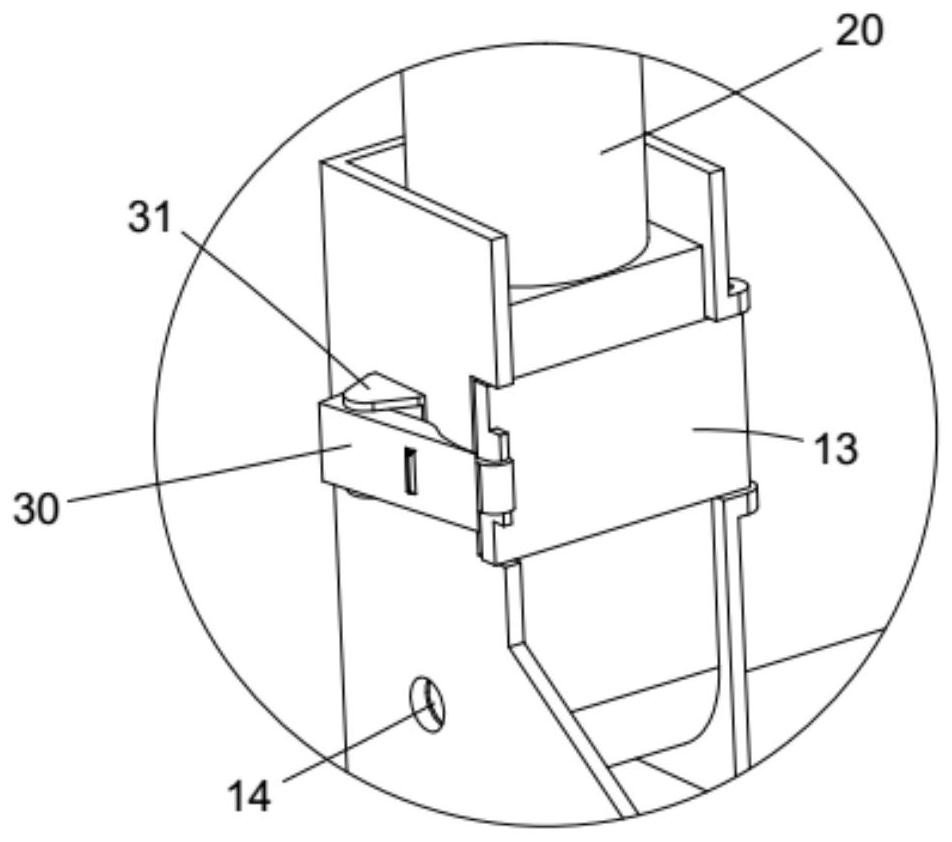

[0026] The four corners of base 10 are provided with support 11, and support is provided with square mounting hole 12, and one side opening of mounting hole is the opening of support, and the bottom of column is hinged in mounting hole by hinge shaft 14; A lock 13 is hinged on one side of the support, and a lock 30 is provided on the outer wall of the support. The lock can lock the lock on the opening side of the installation hole to surround the upright column erected in the installation hole.

[0027] The four supports 11 are respectively the first support, the second support, the third support, and the fourth support, and the first support, the second support, the third support, and the fourth sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com