Yarn drying and winding machine

A winding machine and yarn technology, applied in the directions of drying, drying solid materials, heating to dry solid materials, etc., can solve problems such as quality damage and yarn moldy, and achieve the effect of reducing operation troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

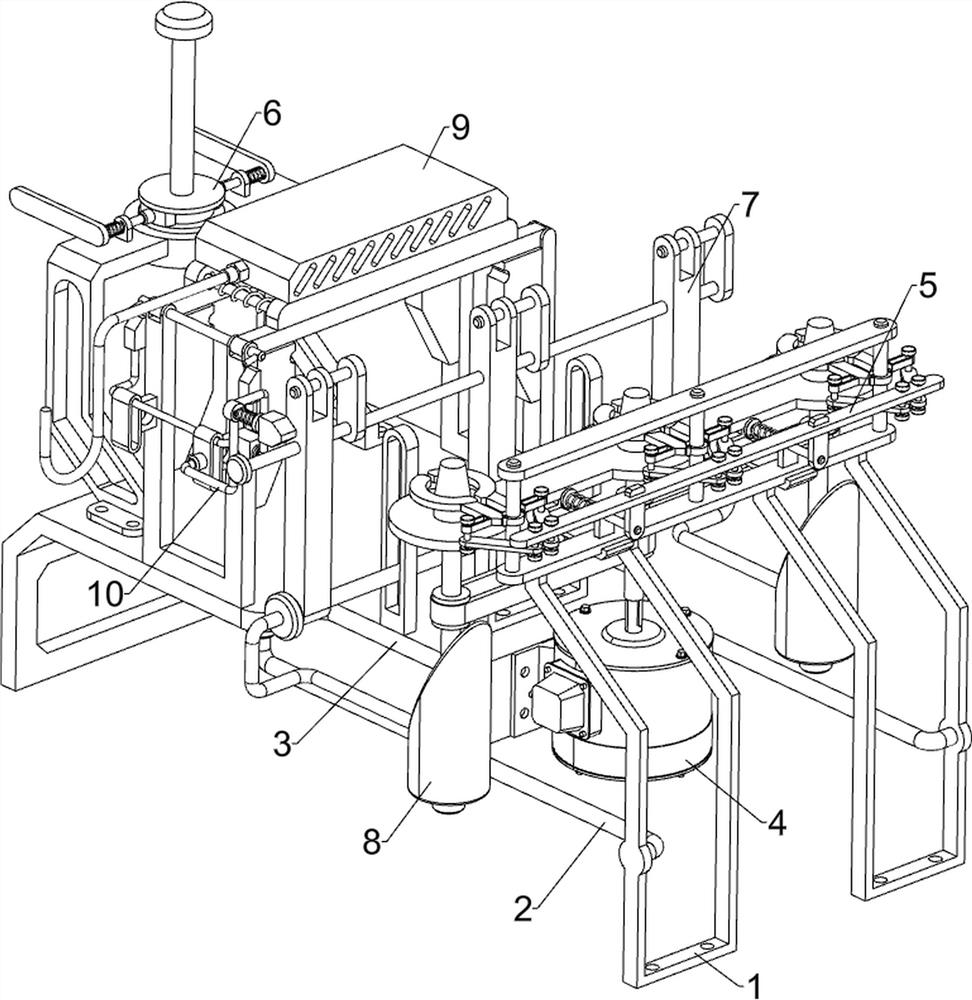

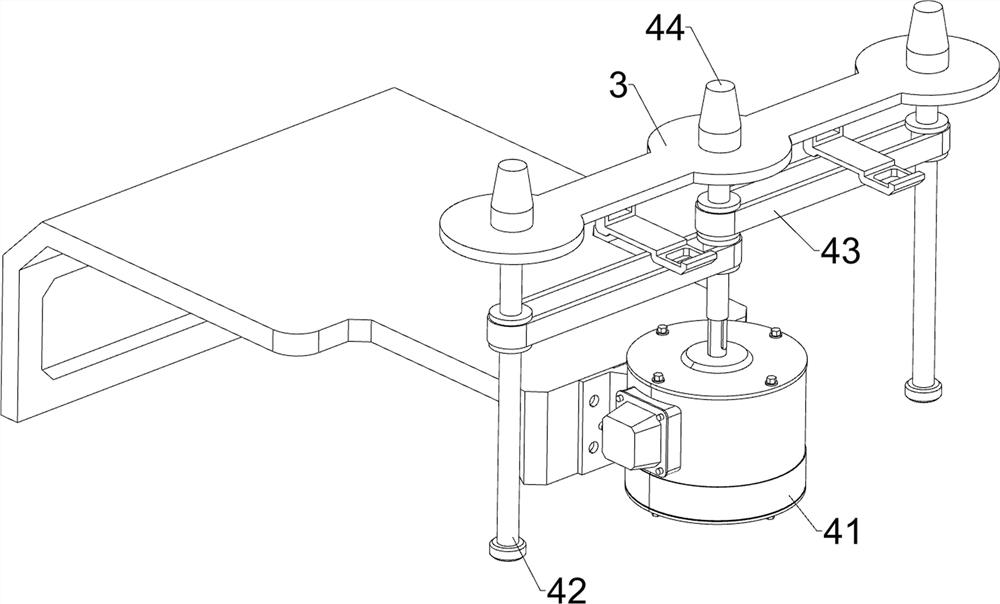

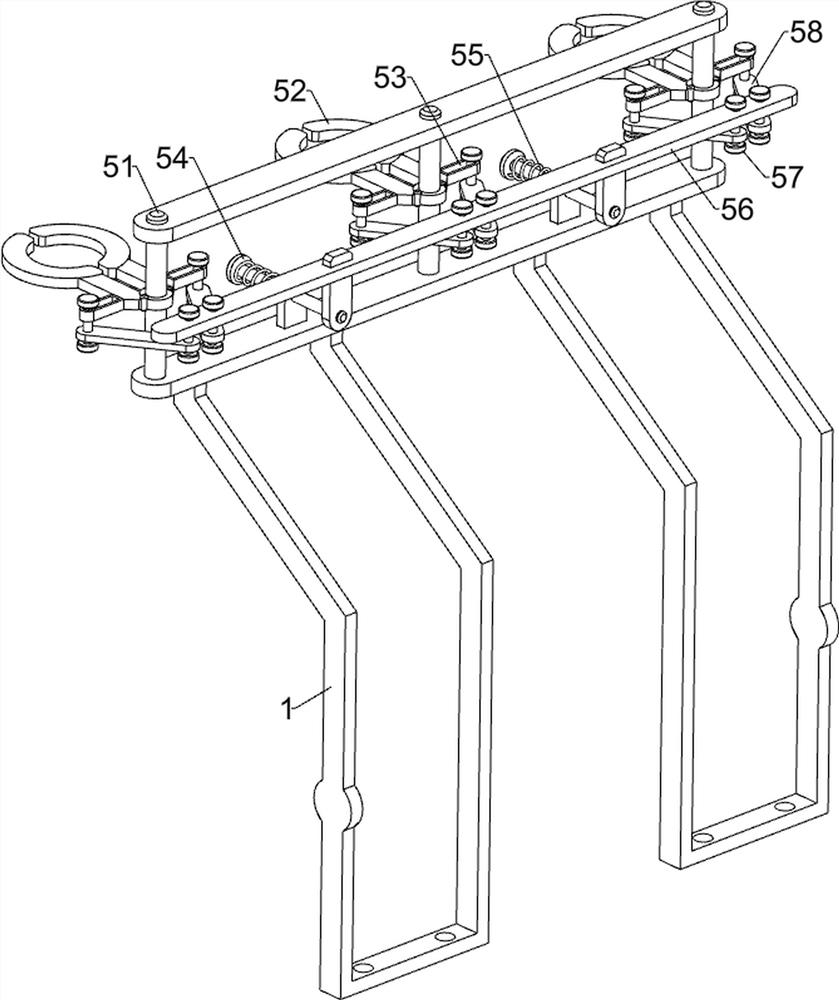

[0029] A yarn drying and winding machine, such as Figure 1 to Figure 4 As shown, it includes a bracket 1, a fixing rod 2, a mounting plate 3, a driving component 4, a clamping component 5 and a clamping component 6. The front and rear sides of the bracket 1 are welded with a fixing rod 2, and the left side of the fixing rod 2 is welded. A mounting plate 3 is connected between the two. The right side of the mounting plate 3 is provided with a driving component 4 , the upper side of the bracket 1 is provided with a clamping component 5 , and the upper side of the mounting plate 3 is provided with a clamping component 6 .

[0030] When the yarn needs to be wound up, the clamping component 6 is controlled to fix the yarn, and then the control yarn is divided into three strands and fixed on the clamping component 5 respectively, and then the driving component 4 is activated, and the driving component 4 will drive the yarn winding When the yarn is wound, close the drive assembly 4,...

Embodiment 2

[0038]On the basis of Example 1, as figure 1 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, it also includes a guide assembly 7. The guide assembly 7 includes a second guide rail 71, a cross bar 72, a bar block 73, a first special-shaped bar 74, a fixed plate 75 and a limit bar 76. The front and rear of the mounting plate 3 The sides are welded with second guide rails 71 , a cross bar 72 is slidably connected between the second guide rails 71 , and three bar-shaped blocks 73 are connected evenly spaced on the cross-bar 72 , and a first special-shaped rod is connected between the bar-shaped blocks 73 . 74. Three fixed plates 75 are connected to the first special-shaped rod 74 at even intervals, and limit rods 76 are connected between the fixed plates 75 and the bar-shaped block 73.

[0039] When the yarn needs to be wound up, the control yarn is divided into three strands and passes between the limiting rod 76 and the first special-shaped rod 74 respectively, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com