Low-cost heavy-load material AGV intelligent transfer device

A transfer device, low-cost technology, applied in the direction of lifting device, transportation and packaging, lifting frame, etc., can solve the problems of high energy consumption, high driving power, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

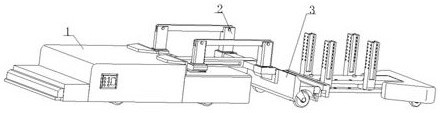

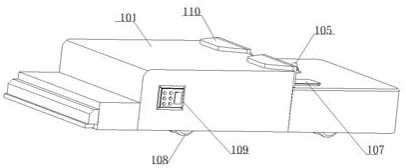

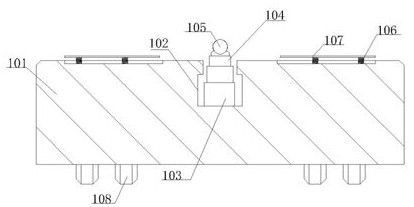

[0038] see Figure 1-5, the present invention provides a technical solution: a low-cost heavy-duty material AGV intelligent transfer device, including AGV equipment 1, the top of the AGV equipment 1 is movably installed with a jacking frame 2, the interior of the AGV equipment 1 includes a machine platform 101, the machine The top of the table 101 is provided with a groove 102, and the inside of the groove 102 is provided with a telescopic column 103, one end of the telescopic column 103 is fixedly connected with the inner wall of the groove 102, and the other end of the telescopic column 103 is provided with a connecting rocker arm 104, which is connected to the rocker. One end of the arm 104 is movably connected with the top of the telescopic column 103, and the other end connected with the rocker arm 104 is movably installed with a ball stud 105. The outer wall of the machine table 101 is provided with a buffer groove, and the inner wall of the buffer groove is fixedly insta...

Embodiment 2

[0041] see Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: one end of the jacking frame 2 is fixedly installed with a material carrying vehicle 3, the interior of the material carrying vehicle 3 includes a mounting frame 301, and the outer wall of the mounting frame 301 is fixed A fixed block 302 is installed, and the bottom of the fixed block 302 is fixedly equipped with a traction front wheel 303, and one end of the fixed block 302 away from the mounting frame 301 is provided with an adapter frame 304, and the outer wall of the adapter frame 304 is fixedly connected with the outer wall of the fixed block 302, and the adapter frame The inside of 304 is provided with hinge column 305, and the two ends of hinge column 305 are fixedly connected with the inner wall of connecting frame 304, and the outside of hinge column 305 is provided with traction plate 306, and the inner wall of traction plate 306 is flexibly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com