System and method for improving efficiency of paper machine

A high-efficiency, paper-machine technology, applied in paper-making, paper-making, textiles and paper-making, etc., can solve the problems of inability to recycle low-temperature steam, low-quality high-end use, and unsatisfactory energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

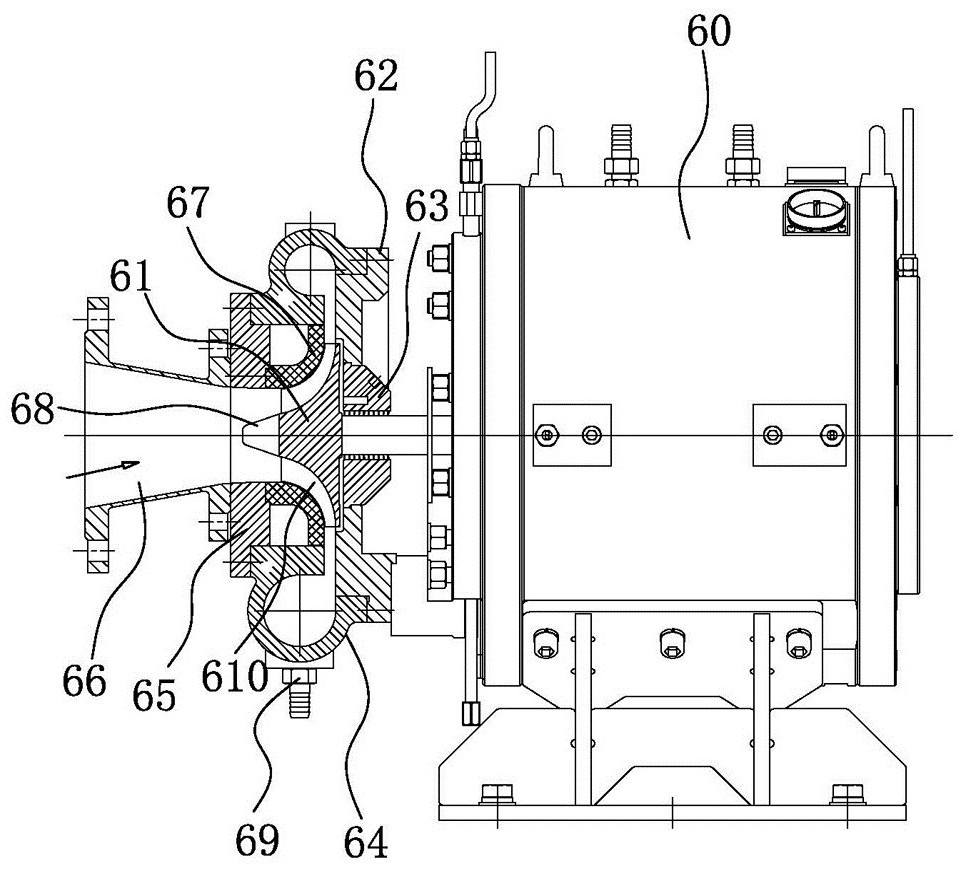

[0026] like figure 1 and figure 2 As shown, a method of improving paper machine efficiency includes the following steps:

[0027] S1. New steam supply pipe 1 supplies new steam from the inlet of dryer 2 to dryer 2. The pressure of new steam is less than 0.6 MPa, for example: 0.5 MPa. Dryer 2 is used to dry special paper. Drying, from the outlet of drying cylinder 2, the new steam is discharged into the steam-water separator 3 after being heat-exchanged by the drying cylinder 2.

[0028] The new steam supply pipe 1 is connected with the inlet of the drying cylinder 2 through a straight pipe.

[0029] The condensed water after the steam-water separator 3 separates and processes the steam-water mixture is discharged from the condensed water discharge system. Preferably, the condensed water discharge system includes a condensed water discharge pipeline 4, and a condensate pump 40 is connected to the condensed water discharge pipeline 4. The condensate pump 40 After the condens...

Embodiment 2

[0054] The working principle and structure of this embodiment are basically the same as those of Embodiment 1, except that the inclined pipe is an arched pipe, and the arch of the arched pipe is arched downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com