Roadbed backfilling auxiliary equipment

A technology of auxiliary equipment and roadbed, applied in construction, earthmoving machine/shovel, etc., can solve the problems of low operation efficiency and slow construction efficiency, and achieve the effect of uniform spreading, improving spreading efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

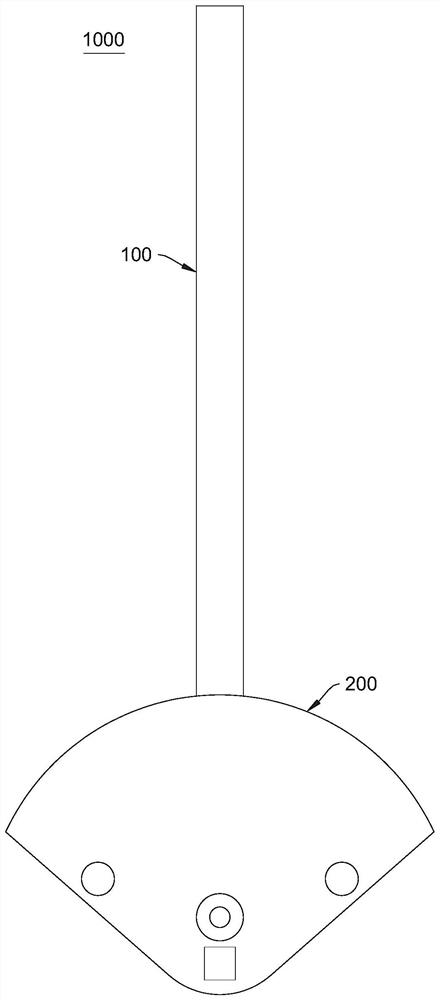

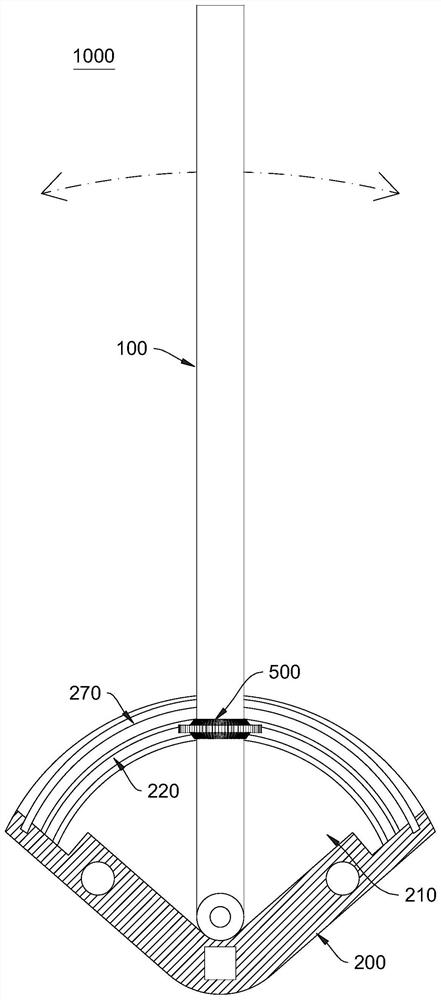

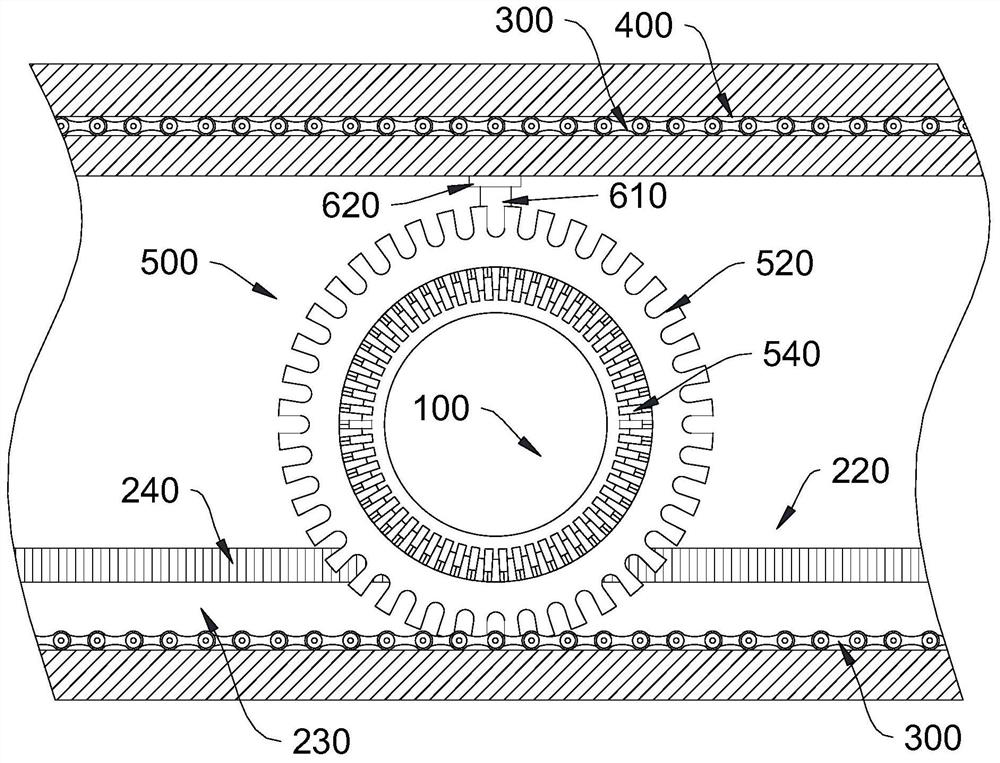

[0040] Please refer to Figure 1~2 , this embodiment provides an auxiliary equipment 1000 for roadbed backfilling.

[0041] The roadbed backfill auxiliary equipment 1000 includes: a swing rod 100 and a base 200 .

[0042] The base 200 has a mounting portion for connecting with an elevating mechanism of an external construction vehicle, so that the base 200 can be assembled in a horizontal direction. One end of the swing rod 100 is hinged to the base 200 , and the other end extends horizontally toward the outside of the base 200 . The base 200 is also installed with a driving assembly (not shown in the figure) for driving the swing rod 100 to perform a reciprocating swinging action.

[0043] During use, the base 200 can be installed on the lifting mechanism of an external construction vehicle, and the construction vehicle can be used to operate the roadbed backfilling auxiliary equipment 1000 . When backfilling the subgrade, after the backfill soil is dumped, under the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com