Construction method of special-shaped slide way

A construction method and slideway technology, which are applied in the directions of buildings, building components, building structures, etc., can solve the problems of different shapes of slideway components and large changes in slideway elevation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] refer to Figure 1 to Figure 3 , a construction method for a special-shaped slideway, comprising the steps of:

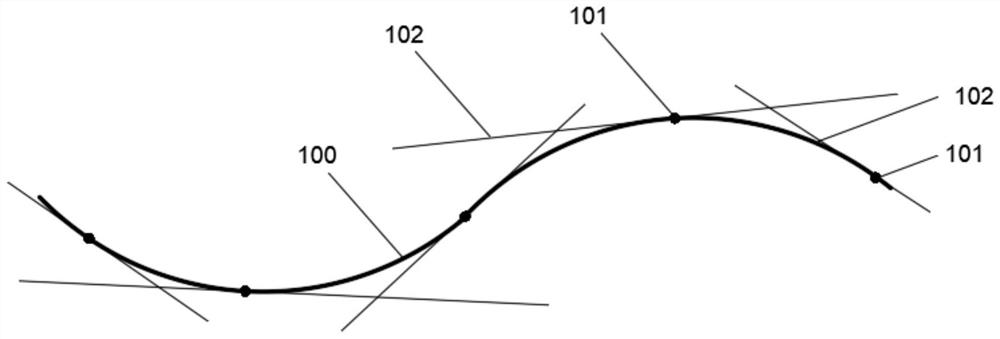

[0028] S1, importing the structure of the special-shaped slideway into BIM modeling software, and establishing a special-shaped slideway model, the special-shaped slideway model includes a special-shaped slideway bottom plate model 100;

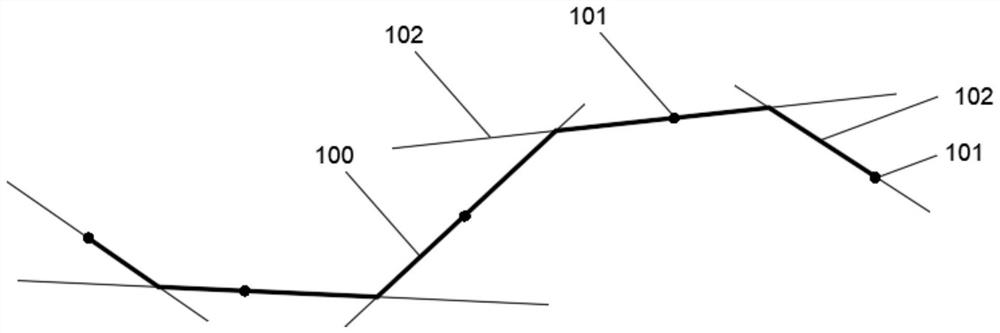

[0029] S2, splitting the special-shaped slideway bottom plate model 100 into several profiled steel plate unit models 103;

[0030] S3, generating the processing dimensions of each profiled steel plate unit model 103;

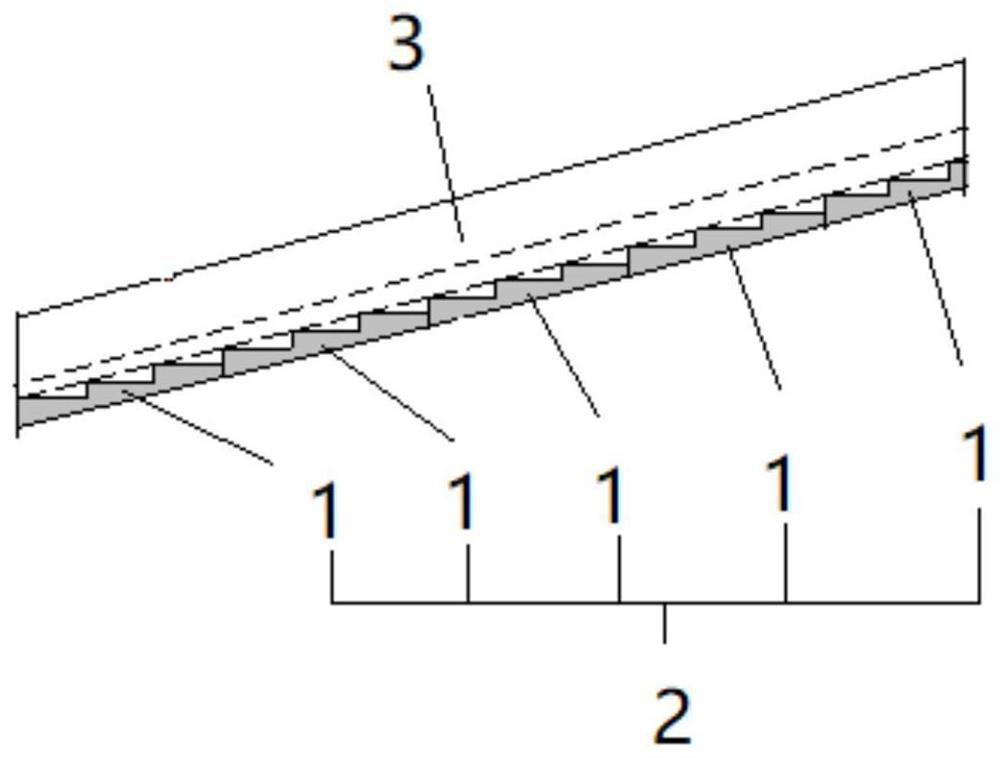

[0031] S4, process the profiled steel plate unit 1 according to the profiled steel plate unit model 103;

[0032] S5, according to the special-shaped slideway bottom plate model 100, each profiled steel plate unit 1 is hoisted in place, and spliced together to form the special-shaped slideway bottom plate 2;

[0033] S6, placing steel bar trusses on the bottom plate of the special-shaped slideway for bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com