An anti-deformation and dust-proof deep groove ball bearing

A deep groove ball bearing, anti-deformation technology, applied in the direction of ball bearings, shafts and bearings, bearing components, etc., can solve the problem of aggravating the degree of wear between the rolling element and the outer ring and the inner ring, the rolling element is stuck, the bearing is scrapped, etc. problem, to achieve the effect of increasing the radial load of the bearing, the state of firm fit, and the radial load of the dust-proof bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

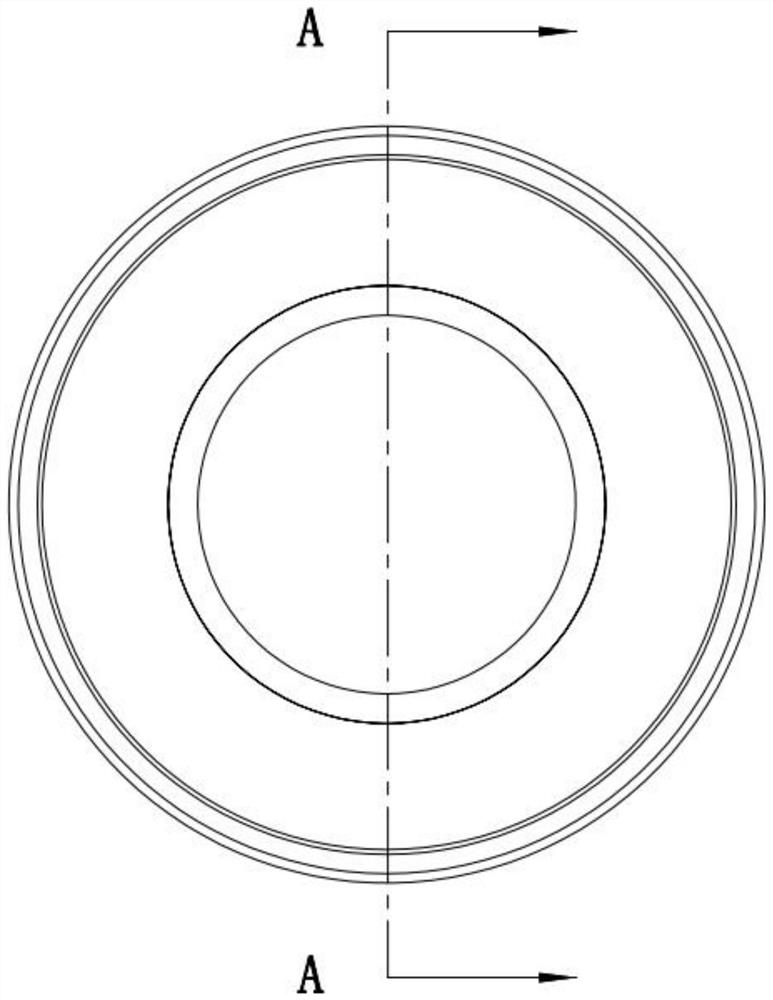

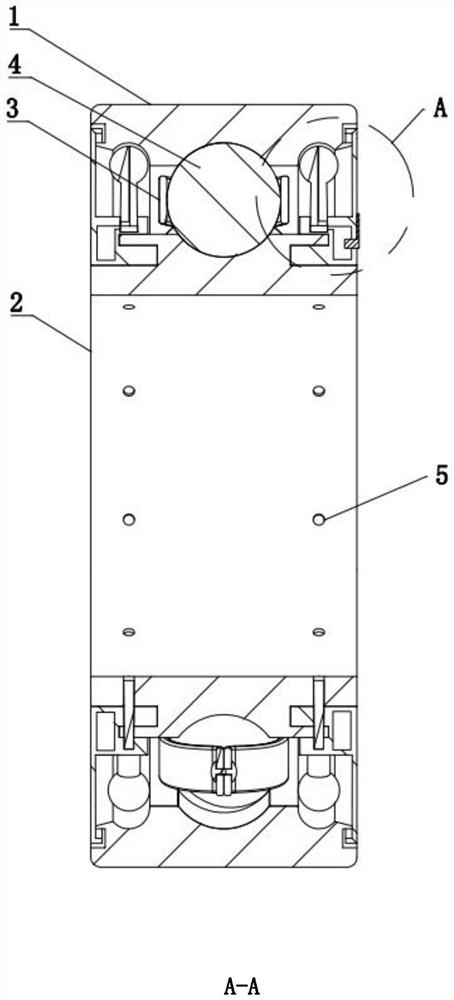

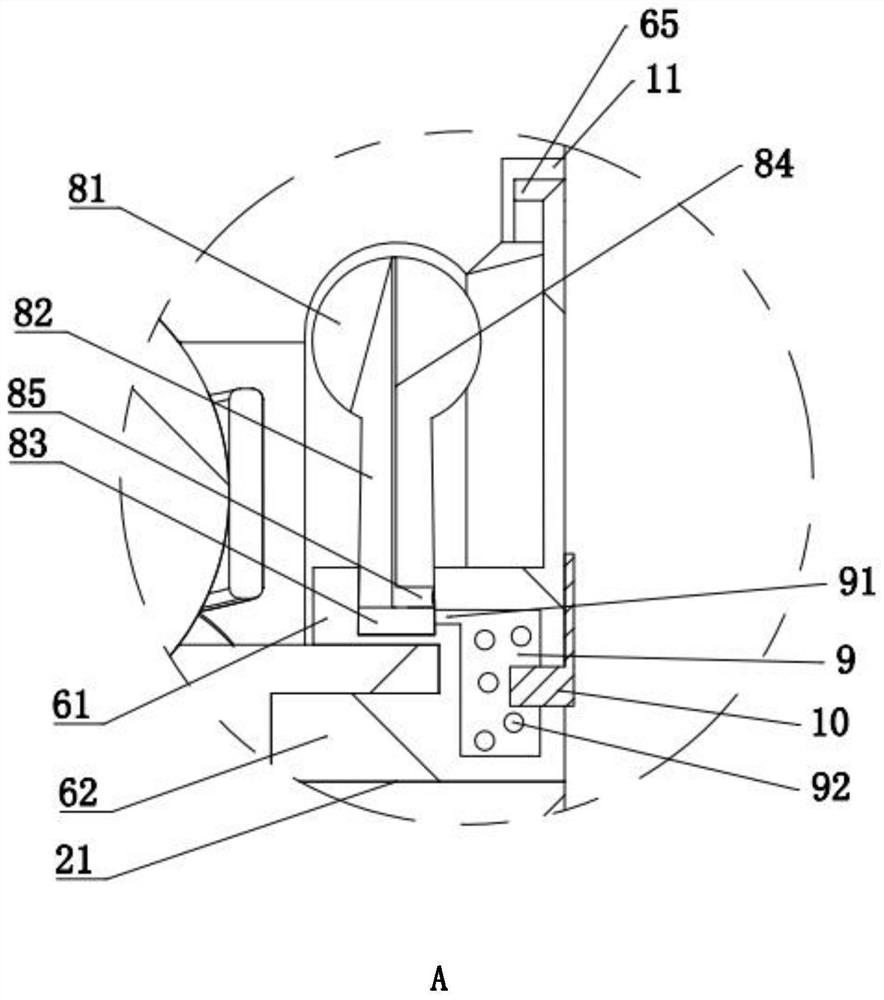

[0025] A type of anti-deformation deep groove ball bearing, reference Figure 1-Figure 4As shown, including the outer ring 1, the inner ring 2, located between the outer ring 1 and the inner ring 2 cage 3 and the circumferential interval distributed on the cage 3 rolling element 4, the inner ring wall of the outer ring 1 and the outer ring wall of the inner ring 2 are respectively provided with a main raceway with the rolling element 4, on both sides of the inner ring 2 is fixed a dust cover 6 that blocks the gap between the inner ring 2 and the outer ring 1, the dust cover 6 is mated with the inner ring 2 plug, and the limit is carried out by the limit mechanism, and the dust cover 6 is matched with the gap after the outer ring 1 is inserted to prevent dust.

[0026] The mating structure of the dust cover 6 and the inner ring 2 is specifically referred to Figure 2 As shown: the two sides of the inner ring 2 are recessed with a concession ring groove 21, the inner wall of the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com