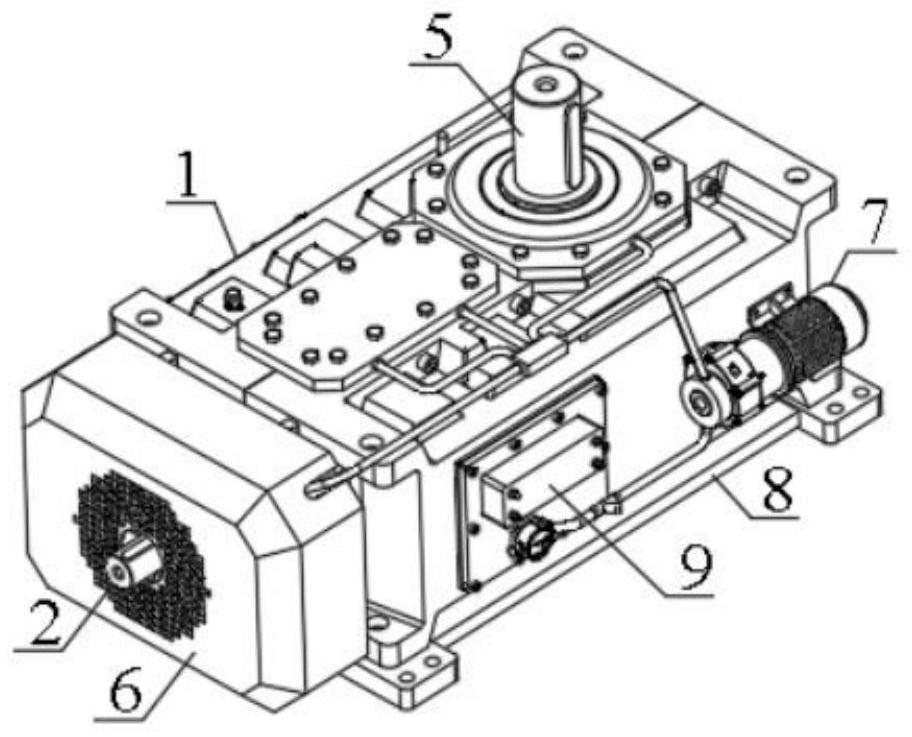

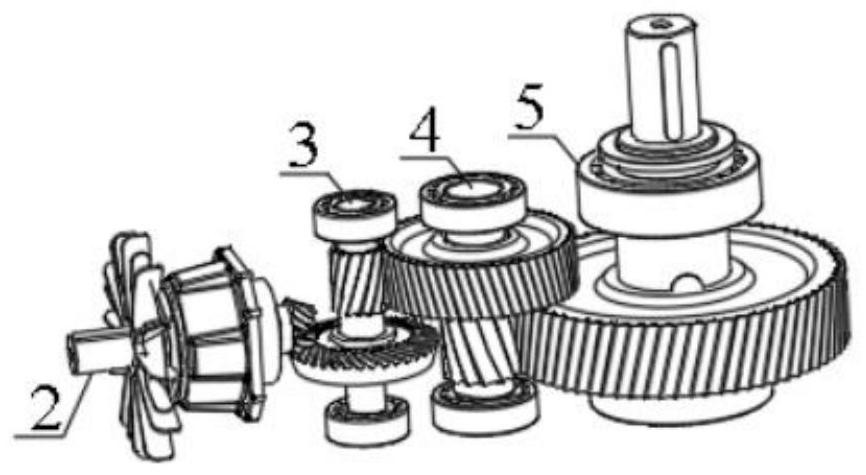

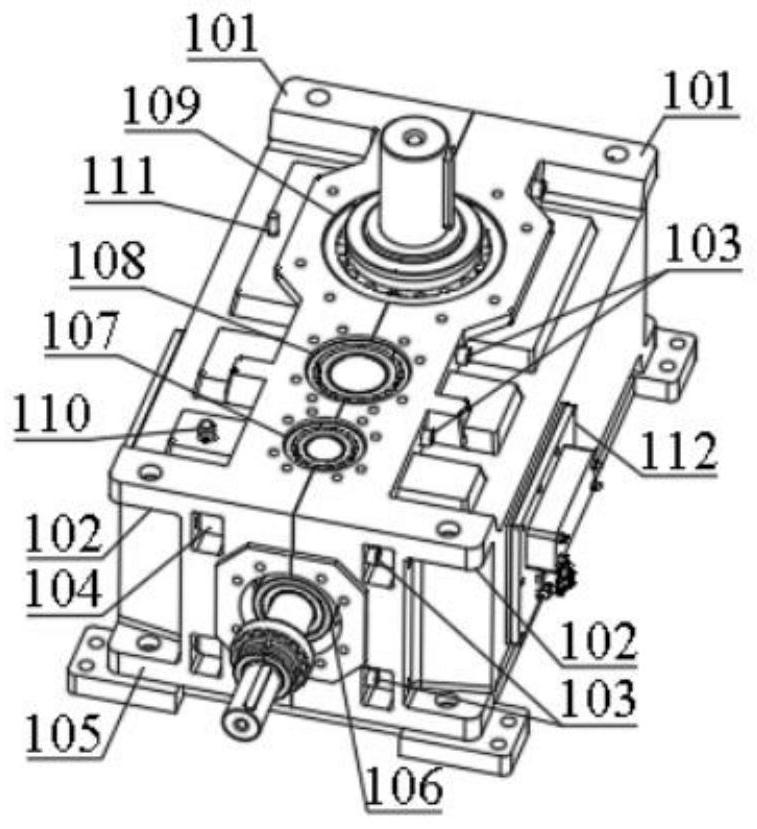

Novel speed reducer

A reducer, a new type of technology, applied in the direction of transmission, toothed components, gear lubrication/cooling, etc., can solve the problems of box cracking, affecting service life and working reliability, bearing damage, etc., to reduce weight and Occupies space, improves work adaptability, and is easy to produce and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In describing the present invention, it should be understood that relational terms such as first and second etc. are only used to distinguish one entity or operation from another entity or operation and do not necessarily require or imply that these entities or operations, any such actual relationship or order exists. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article or apparatus comprising a set of elements includes not only those elements, but also includes elements not expressly listed. other elements of or also include elements inherent in such a process, method, article, or device. Also, the terms "center", "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", "bottom", "inner ", "outside" and other indicated orientations or positional relationships are based on the orientations or positional relationships shown in the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com