Heliostat

A technology for heliostats and mirrors, applied in the field of heliostats, can solve the problems of increased equipment cost, reduced rigidity of support devices, and very high rigidity requirements of transmission systems, and achieves the effects of easy control, easy processing, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The heliostat of the present invention will be described in detail below in conjunction with the accompanying drawings.

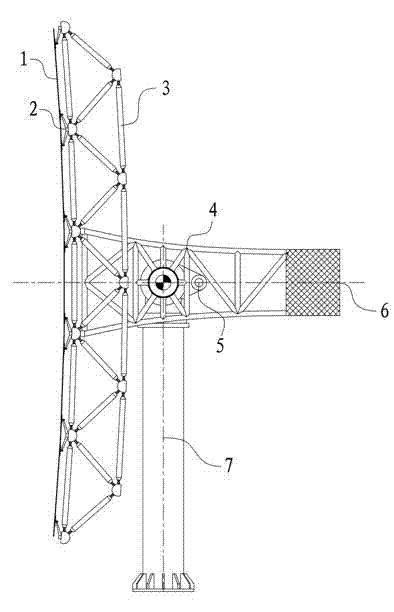

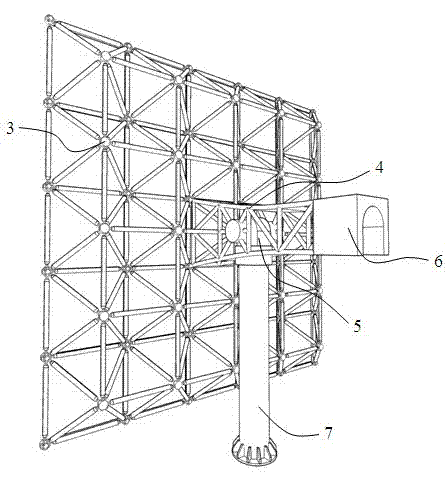

[0025] Such as figure 1 As shown, the heliostat of the present invention includes a converging curved surface (ie, a reflector) spliced by several reflector units 1 , a support device for fixing the reflector, and a transmission mechanism 5 . Wherein the supporting device includes a column 7, a supporting grid 3, a counterweight clamping device 6 and a truss beam 4. The truss beam 4 is connected with the column 7 through the transmission mechanism 5 . The support grid 3 and the counterweight clamping device 6 are respectively installed at both ends of the truss beam 4 .

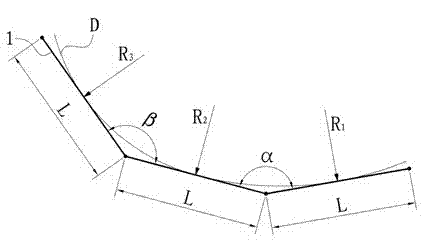

[0026] refer to image 3 As shown, any curve D can be tangent to the curve by changing the included angles α and β between adjacent reflector units 1, and the curvature of the curve D is very small in actual use requirements, so it can be considered that the tangent point and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com