Oil pipe protection device

A protection device and oil pipeline technology, which is applied in pipeline protection, pipeline anti-corrosion/rust protection, and pipeline protection through thermal insulation, etc., can solve the problem that the flame-retardant protection function of oil pipeline cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

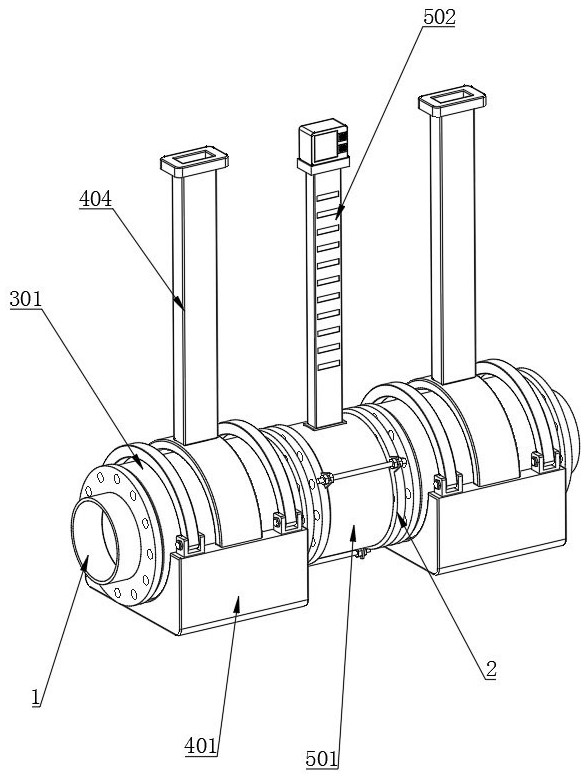

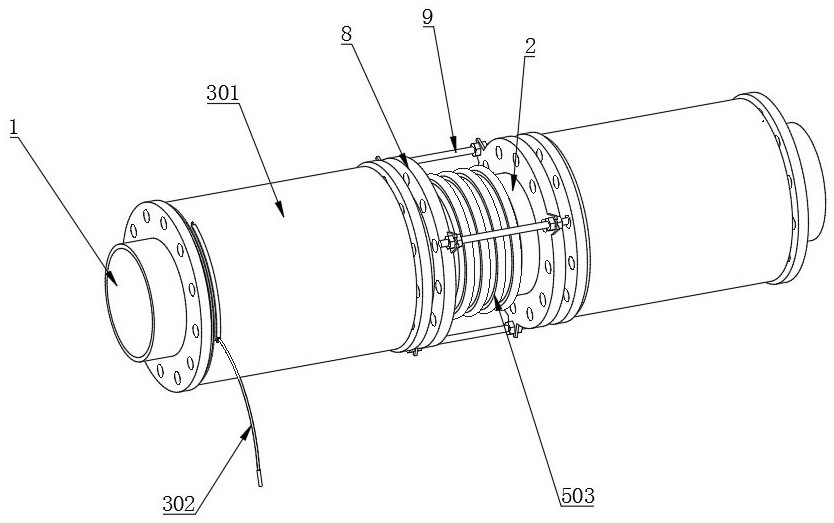

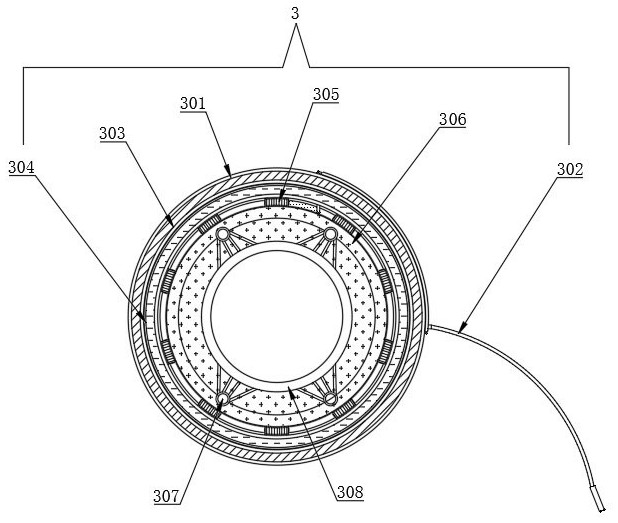

[0024] Example: see Figure 1-Figure 6 , wherein, an oil pipeline protection device includes an oil pipeline 1 and a connecting sleeve 2, the connecting sleeve 2 is fixedly clamped and installed on the outer side of the oil pipeline 1, and the outer sleeve of the oil pipeline 1 is installed with a protection mechanism 3, the protection mechanism 3 A fixing mechanism 4 is fixedly installed on the outside, an early warning mechanism 5 is installed on the outer socket of the connecting sleeve 2, and the protection mechanism 3 includes a protective outer sleeve 301, an electronic wire 302, a puncture-resistant layer 303, an insulation layer 304, a pressure sensor 305, a flame-retardant The rubber ring 306, the shrinking claw arm 307 and the fixed inner ring 308, the protective outer sleeve 301 is socketed and installed outside the oil pipeline 1, the electronic wire 302 is embedded and installed on the inner side of the protective outer sleeve 301, and the puncture-resistant layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com