Fluid compensation type air conditioning system, control method, computer equipment and terminal

An air-conditioning system and control method technology, which is applied in the field of computer equipment and terminals, and liquid-replenishing air-conditioning systems, and can solve problems such as low heat exchange capacity and energy efficiency, small aperture, and high dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

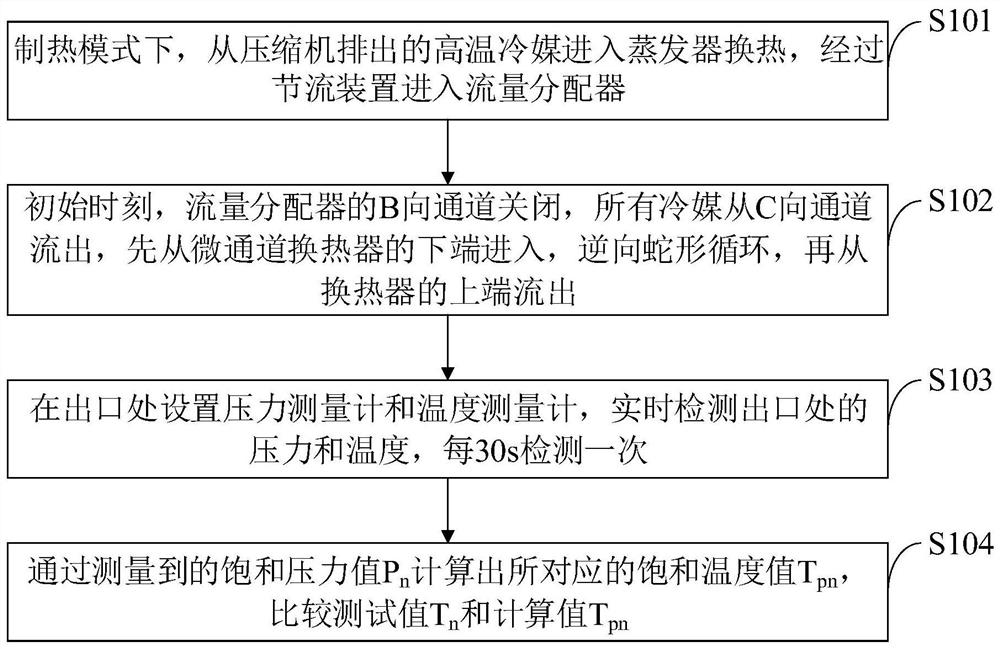

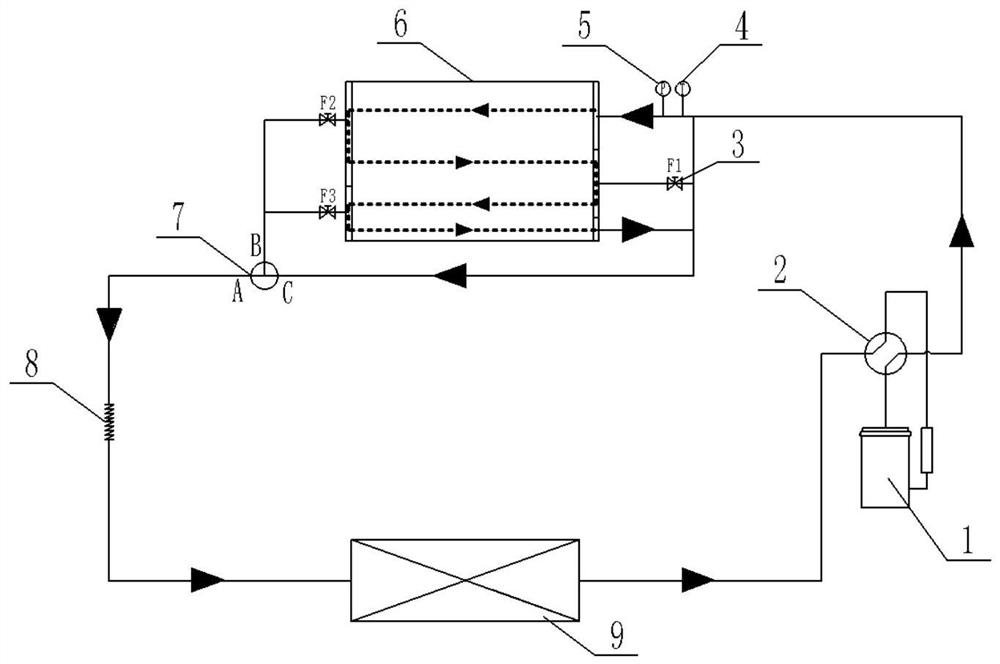

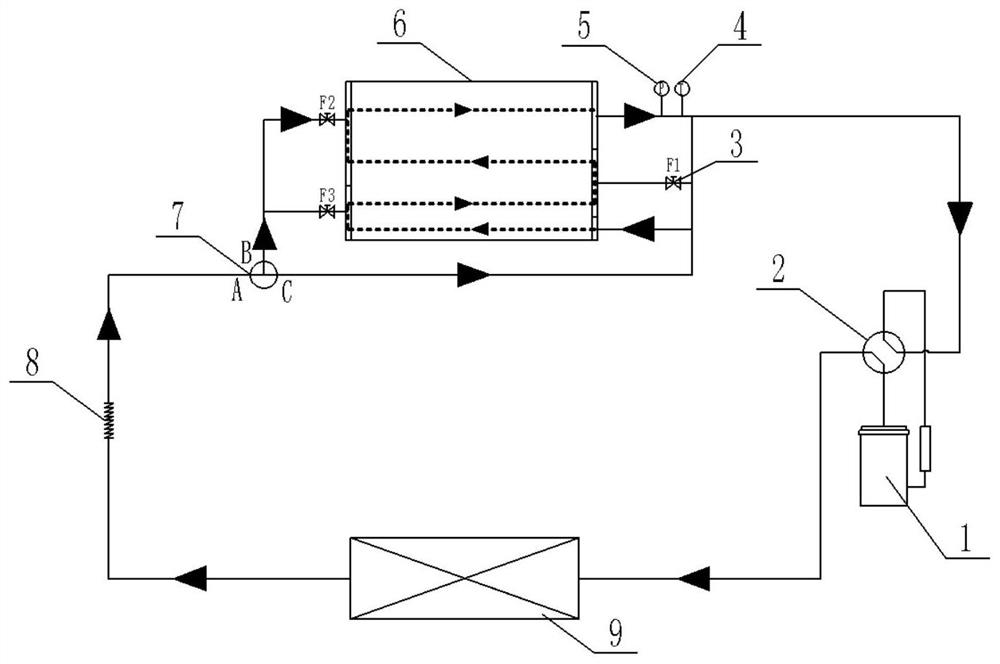

[0041] This implementation mode provides a control method for realizing the uniform flow distribution of the outdoor microchannel heat exchanger by replenishing liquid in the heating mode, such as figure 2 In the circulatory system shown, the names of the system components are as follows:

[0042]Among them, 1 is a compressor, 2 is a four-way valve, 3 is a stop valve (including the first stop valve F1, the second stop valve F2 and the third stop valve F3), 4 is a temperature gauge, 5 is a pressure gauge, 6 is an outdoor micro-channel heat exchanger, 7 is a flow distributor, 8 is a throttling device (no throttling effect, only plays the role of flow distribution), and 9 is an indoor heat exchanger.

[0043] Such as figure 2 As shown, in the cooling mode, after the refrigerant flows out from the compressor exhaust port, it enters the heat exchanger from the upper end of the outdoor micro-channel heat exchanger. The lower end of the heater flows out (as shown by the dotted li...

Embodiment 2

[0052] Taking a 9K split model as an example, the condenser uses a parallel micro-channel heat exchanger, and the capacity and energy efficiency are tested under three working conditions: rated cooling, rated heating (high temperature) and rated heating (low temperature) respectively (see Table 1) Compared with the performance of the non-replenishment air-conditioning system, under the rated heating (high temperature) and rated heating (low temperature) conditions, the capacity of the refilling air-conditioning system is increased by 10.8% and 19.1%, respectively, and the energy efficiency is increased by 3.9%. and 11.4%. The lower the outer working condition, the more obvious the contrast enhancement effect.

[0053] The fluid replenishment air conditioning system in the present invention is in the same flow process as the original non-fluid replenishment air conditioning system under the rated cooling condition, so the performance test conditions are comparable.

[0054] Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com