Patents

Literature

57results about How to "Realize continuous heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

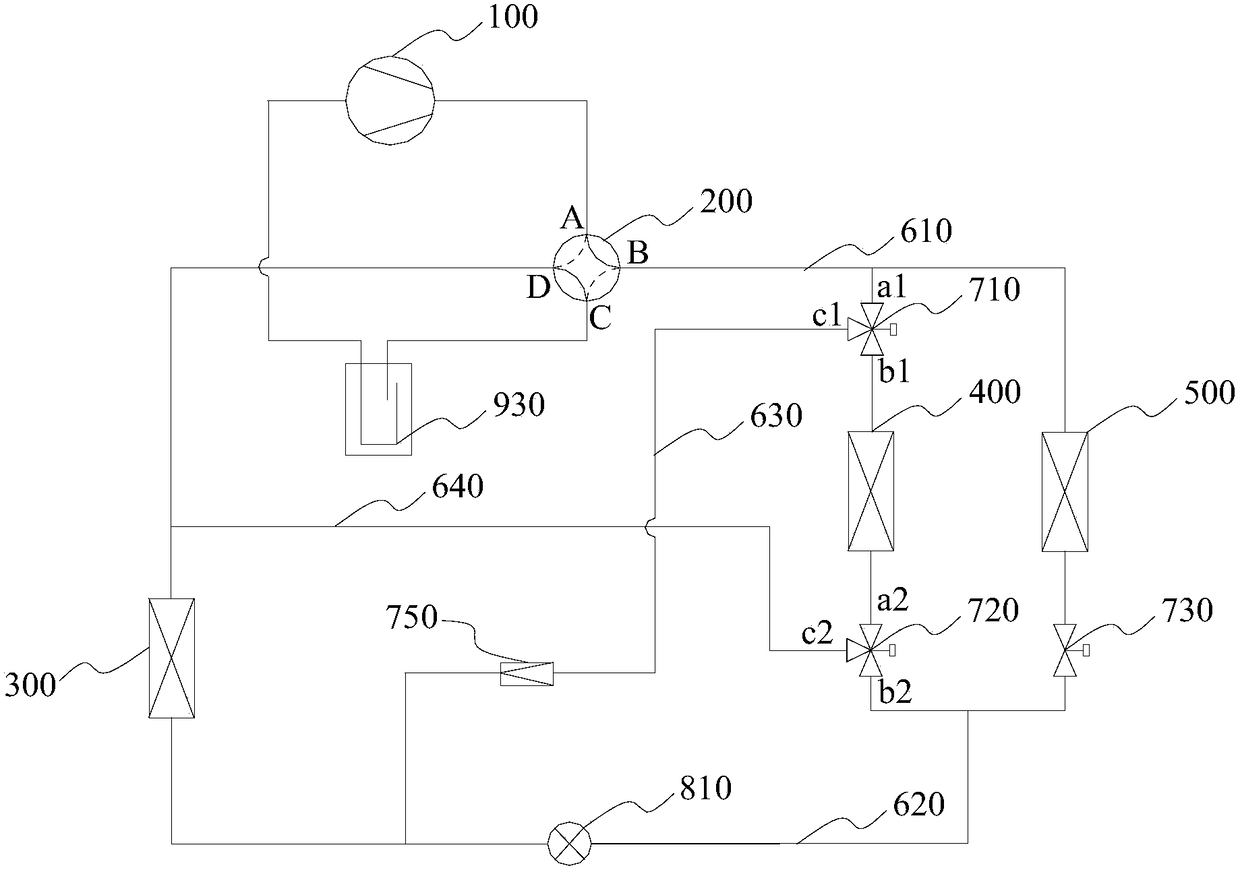

Air conditioning system being able to achieve continuous heating

ActiveCN104515322ARealize continuous heatingImprove distributionMechanical apparatusFluid circulation arrangementRecuperatorEngineering

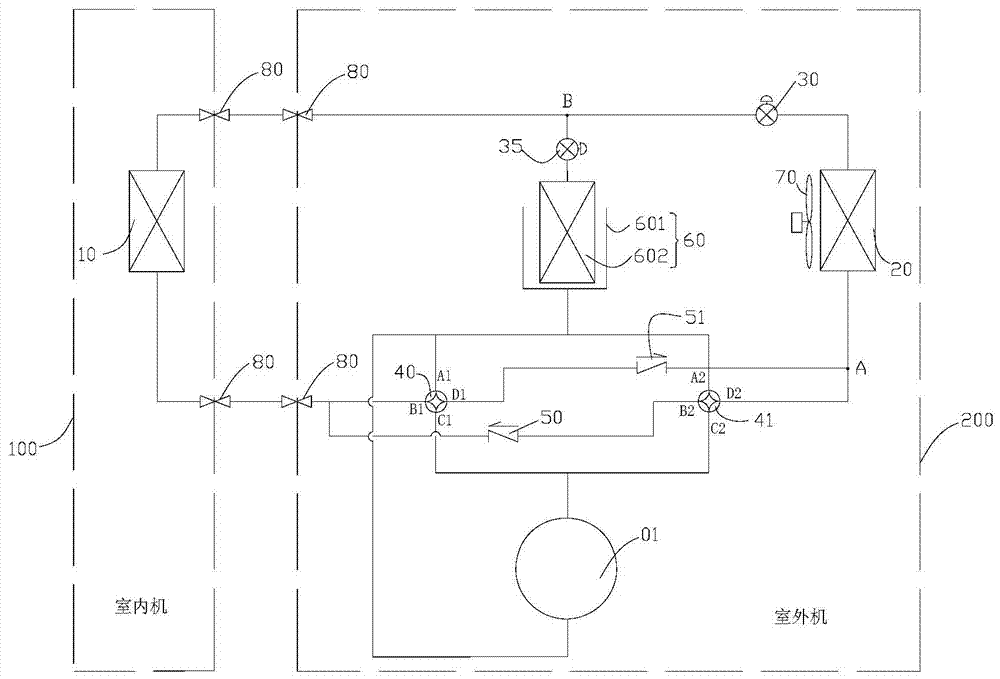

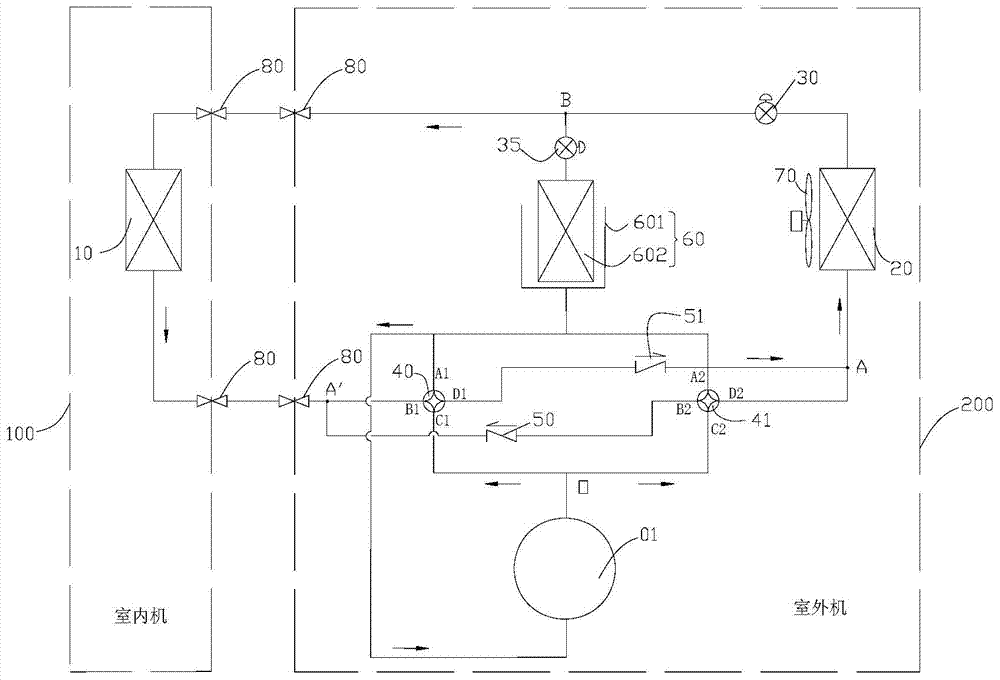

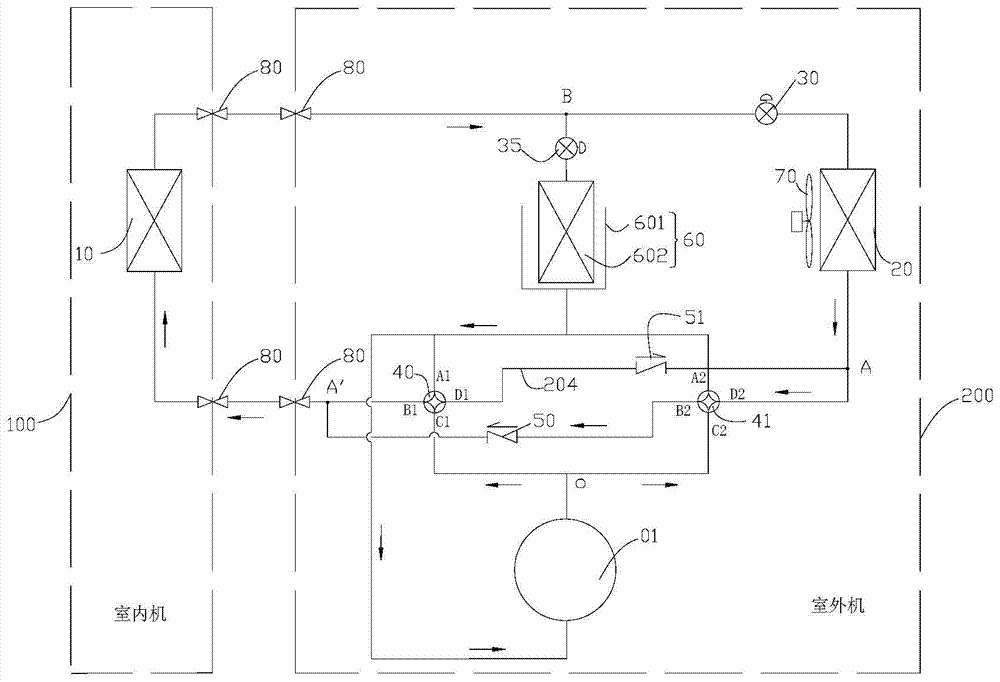

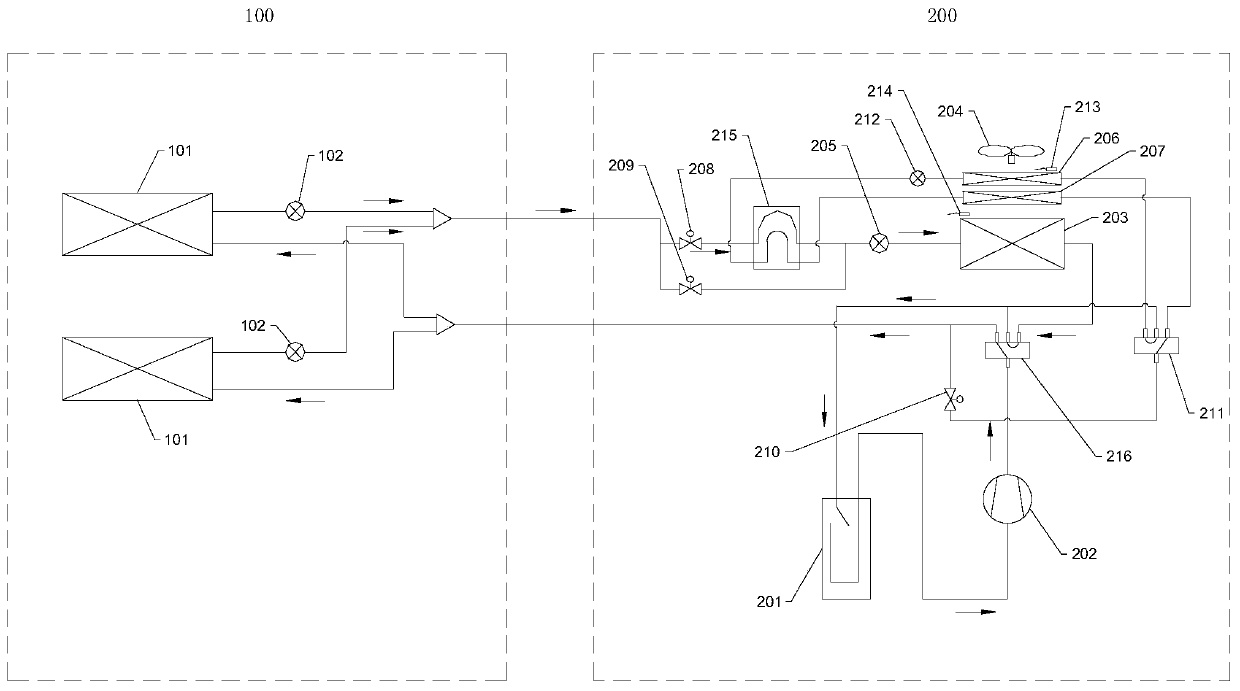

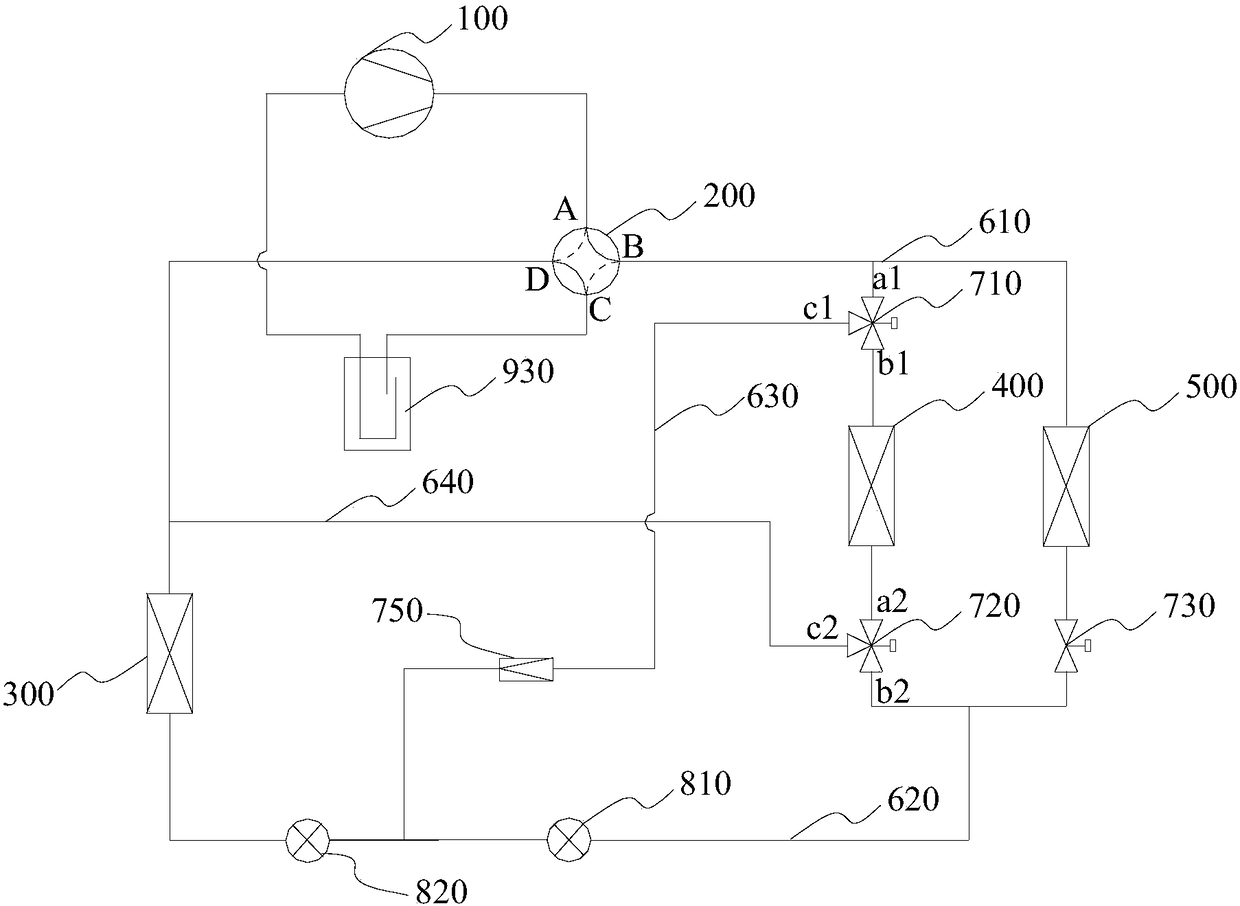

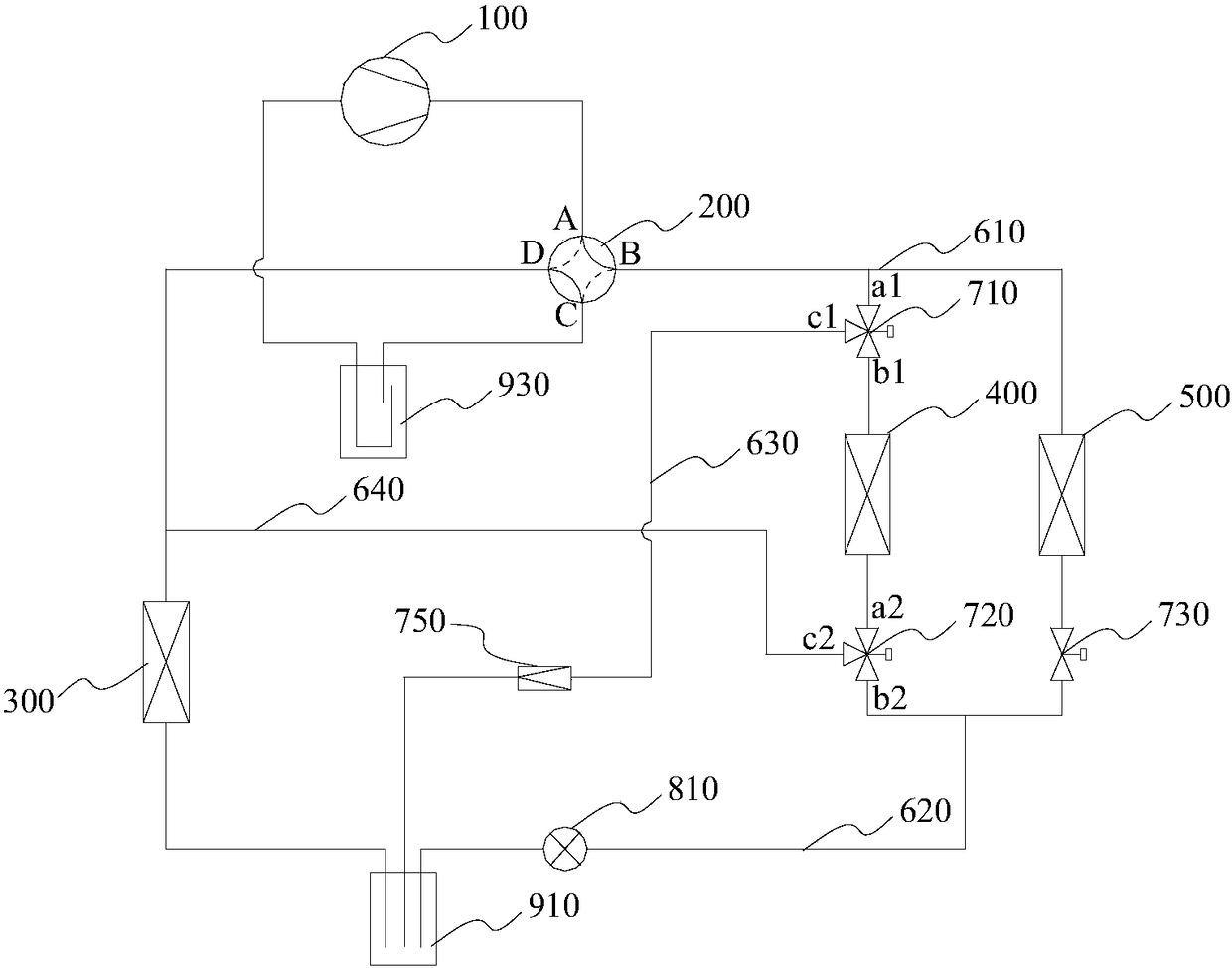

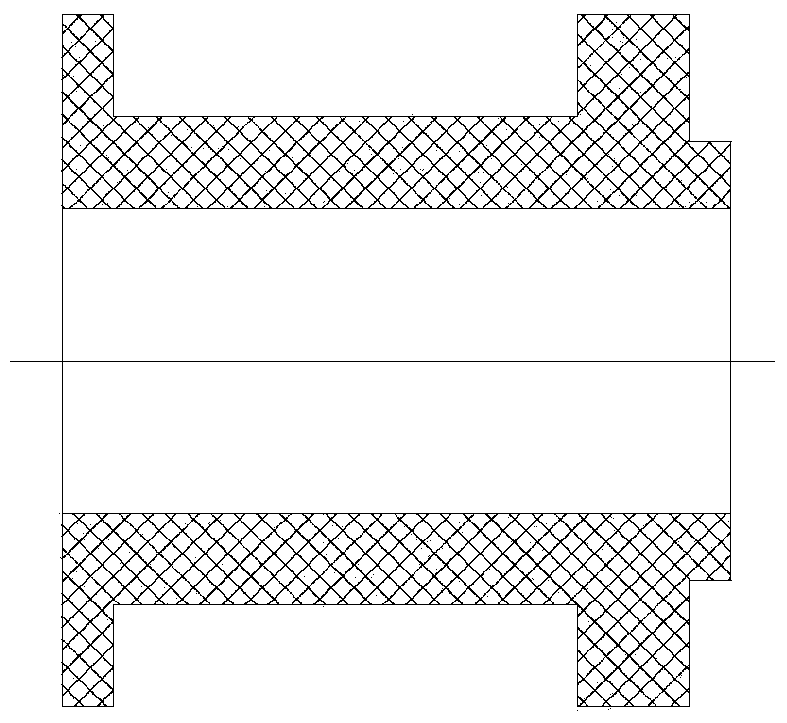

The invention provides an air conditioning system being able to achieve continuous heating; a compressor, a switching device, an outdoor heat exchanger, a throttle element and an indoor heat exchanger are sequentially connected in order to form a refrigeration loop; a heat accumulation device is cascaded between the first end of the throttle element and the switching device; the second end of the throttle element is communicated with the outdoor heat exchanger; the air conditioning system has a first heating mode and a second heating mode; under the first heating mode, the refrigerant discharged by the compressor sequentially enters the indoor heat exchanger, the throttle element, and the outdoor heat exchanger via the switching device; under the second heating mode, the refrigerant discharged by the compressor passes through the switching device, one path thereof enters the indoor heat exchanger, the other path enters the outdoor heat exchanger; the refrigerant flows out from the outdoor heat exchanger and the indoor heat exchanger enters an air suction end of the compressor via the heat accumulation device. The air conditioning system being able to achieve continuous heating enables the heat pump air conditioner to heat continuously while the air conditioner is working to heat; the flux of refrigerant flows into the indoor heat exchanger and the outdoor heat exchanger are easier to be distributed.

Owner:GREE ELECTRIC APPLIANCES INC

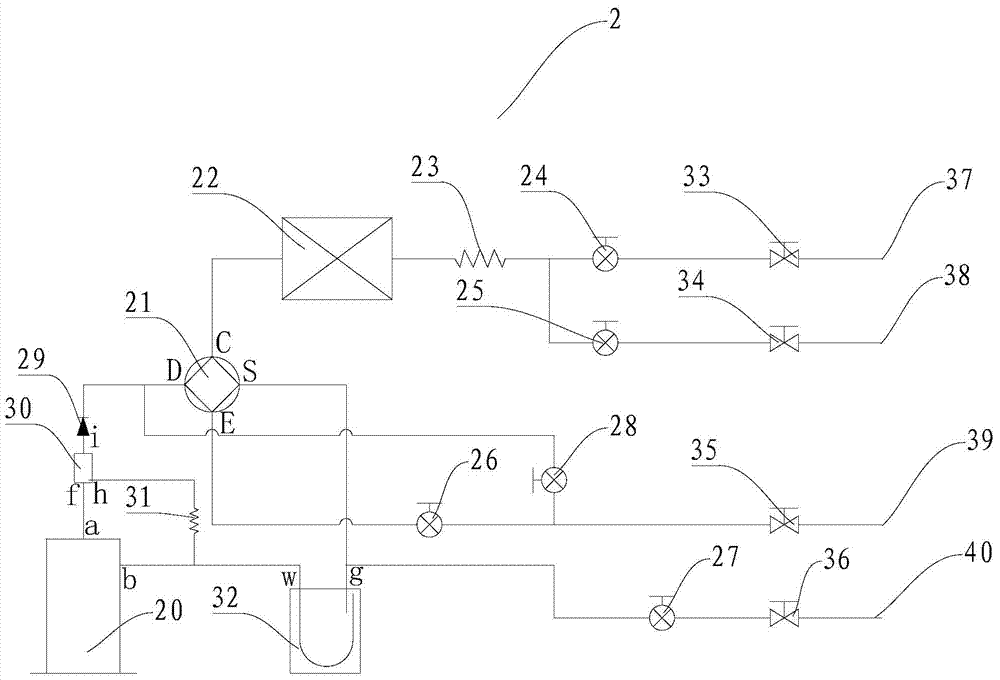

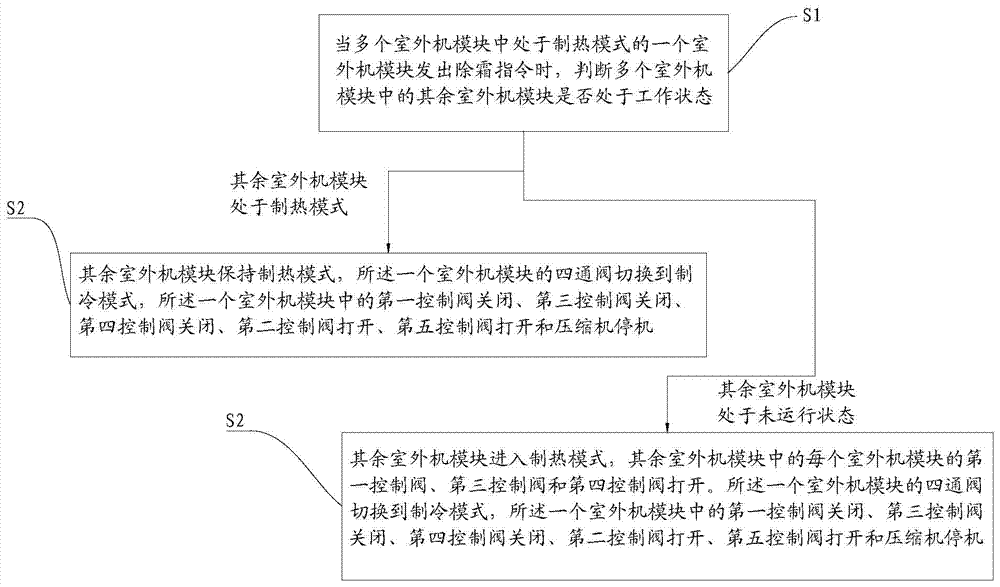

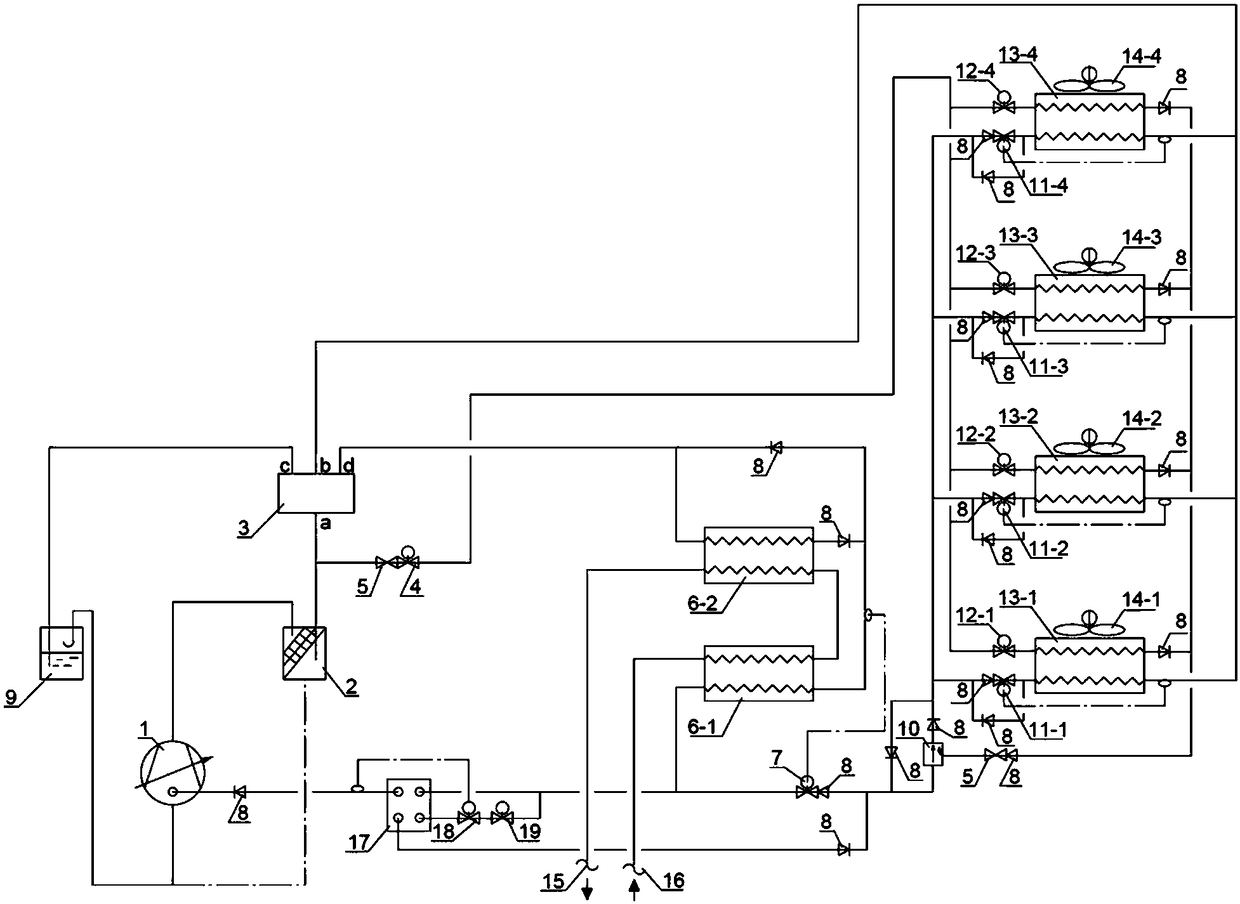

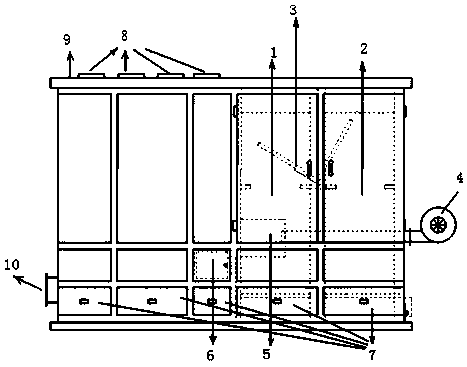

Multi-connected air conditioning system and defrosting control method thereof

ActiveCN104764111ARealize continuous heatingImprove comfortMechanical apparatusSpace heating and ventilation safety systemsFour-way valveAir conditioning

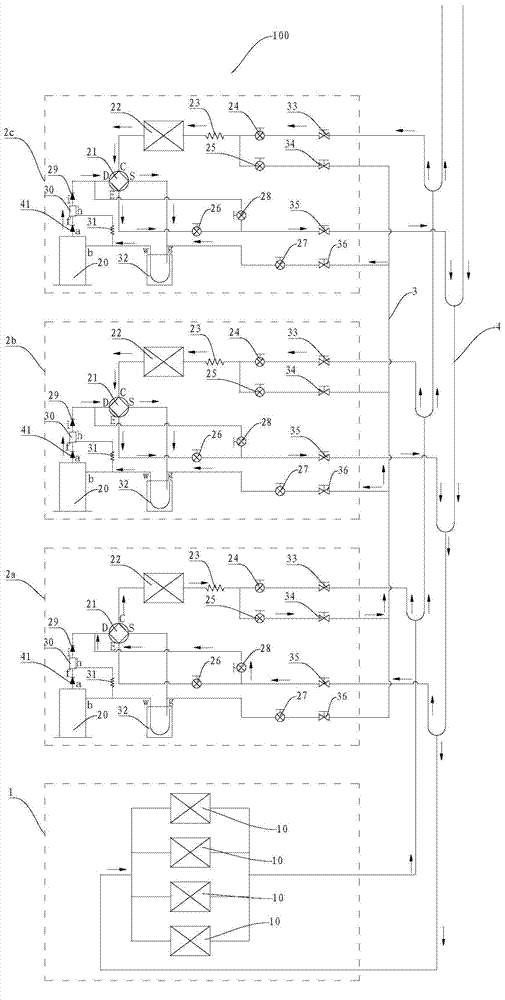

The invention discloses a multi-connected air conditioning system and a defrosting control method thereof. The multi-connected air conditioning system comprises an indoor unit module and a plurality of outdoor unit modules connected in parallel, wherein each outdoor unit module comprises a compressor, a four-way valve, an outdoor heat exchanger, a first throttling element, a first control valve, a second control valve, a third control valve, a fourth control valve, and a fifth control valve; each first control valve is connected between the corresponding first throttling element and the indoor unit module; each second control valve is connected with the corresponding first throttling element; and each second control valve is connected to a first public pipeline; each third control valve is connected with a corresponding fourth control valve port; each third control valve is connected to a second public pipe; and the second public pipe is connected with the indoor unit module; each fourth control valve is connected with a second valve port and the first public pipe; each fifth control valve is connected with a first valve port and the second public pipe. According to the invention, continuous heating during defrosting is realized, and the indoor unit module does not stop, so that comfortability is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

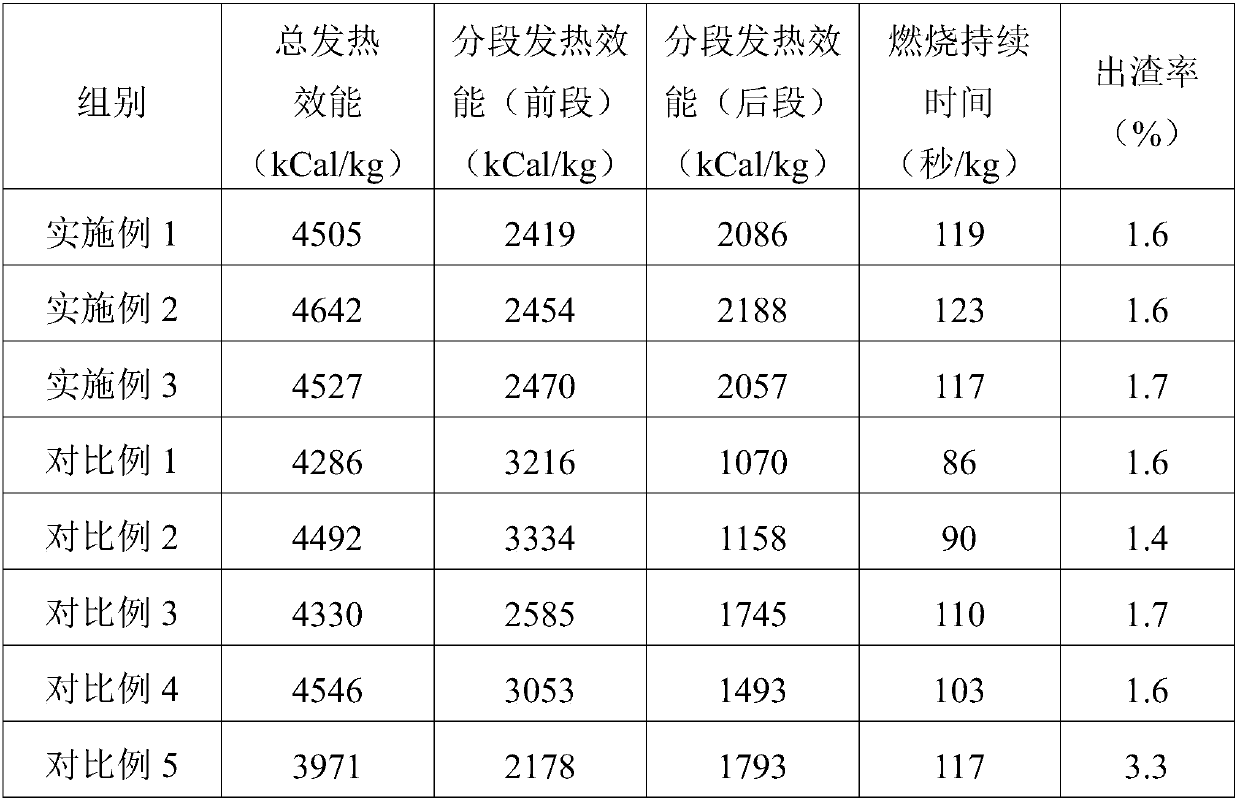

Composite biomass particle fuel

InactiveCN107779235AImprove combustion effectModerate burning rateBiofuelsSolid fuelsEngineeringGraphene

The invention relates to the technical field of biomass fuels, in particular to a composite biomass particle fuel which is prepared from fuel substrates, graphene and coconut shell powder. The fuel substrates are prepared from wheat straws, wood chips, corncobs, peanut shells, rice straws, rice hulls, oil-tea shells and cottonseed hulls. The composite biomass particle fuel has the advantages thatthe fuel is high in combustion efficiency, moderate in combustion speed and long in combustion continuing time, combustion heat can be gently released, heat is continuously supplied and the like. Thefuel is quite suitable for meeting production requirements of finish machining enterprises.

Owner:固始龙海新能源科技有限公司

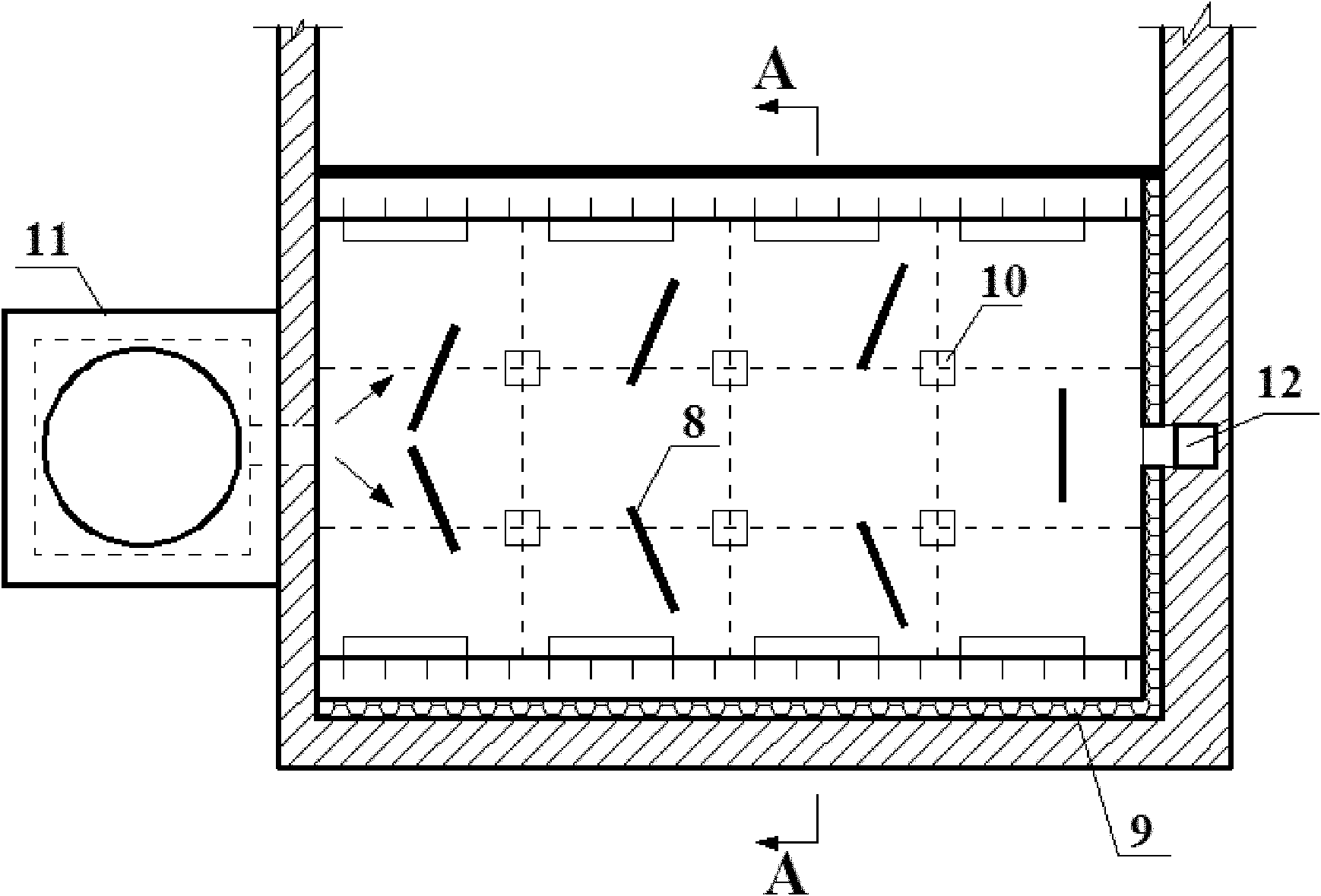

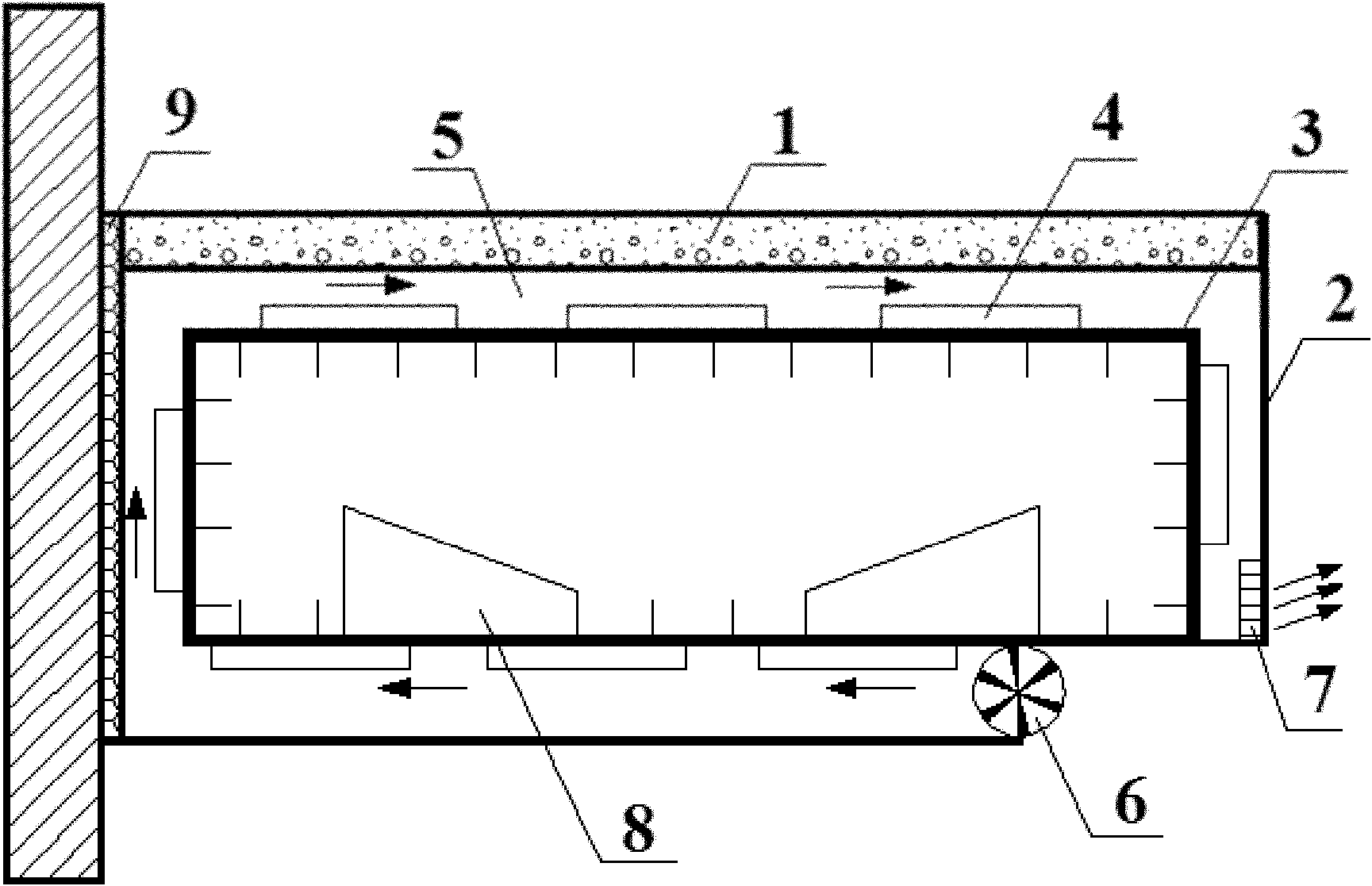

Convection heating Kang

InactiveCN102012046AEnhance overall heating capacityMeet sleeping comfortLighting and heating apparatusCombustion-air/flue-gas circulation for stovesIndoor airEngineering

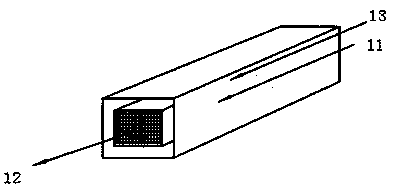

The invention discloses a convection heating Kang, and relates to the technical field of building heating equipment. The Kang comprises a Kang face plate and an outer Kang body; an inner Kang body is arranged in the outer Kang body, so that a sealed air flow channel between the inner Kang body and the outer Kang body is formed; one end, positioned on the bottom of the inner Kang body, of the air flow channel is provided with a fan; one end, positioned on the side of the outer Kang body, of the air flow channel is provided with an air outlet; the inner Kang body is a rectangular cylinder with openings at two ends; outer side and inner side surfaces of the rectangular cylinder are both provided with fins; and one end of the rectangular cylinder is connected with a smoke outlet of a stove and the other end of the rectangular cylinder is connected with a smoke outlet of the Kang. The inner Kang body of the Kang serves as a heat exchanger for hot smoke and air, can improve the overall heat supply capacity of the Kang, effectively solves the problem that a common Kang has insufficient capacity of heating indoor air, and ensures that the Kang meets sleeping comfort and meets the comfort requirement of all-day indoor thermal environment in winter simultaneously.

Owner:TSINGHUA UNIV

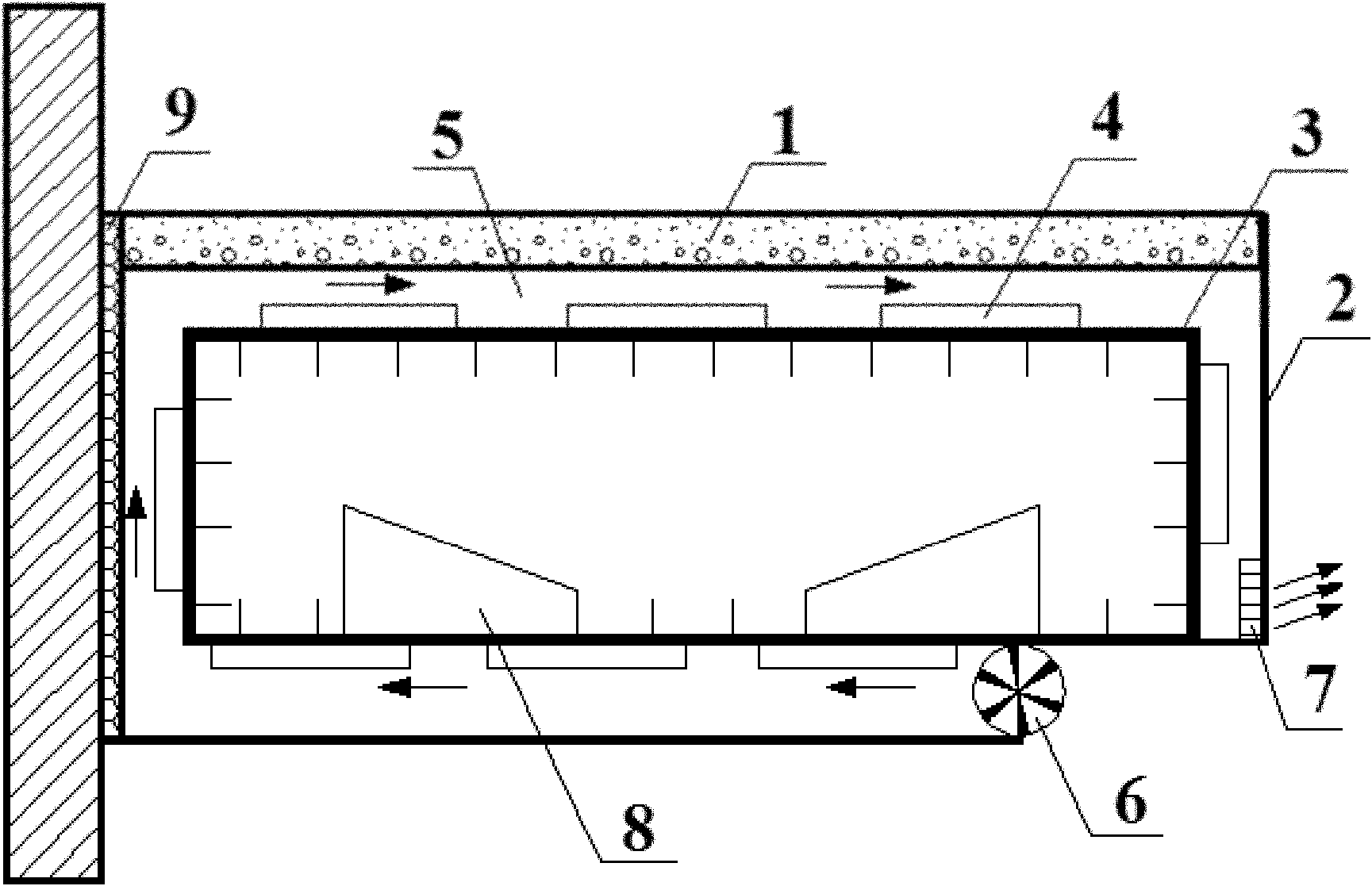

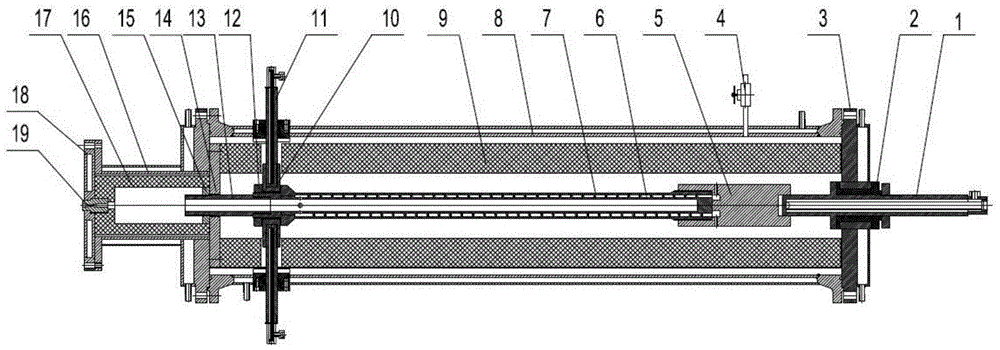

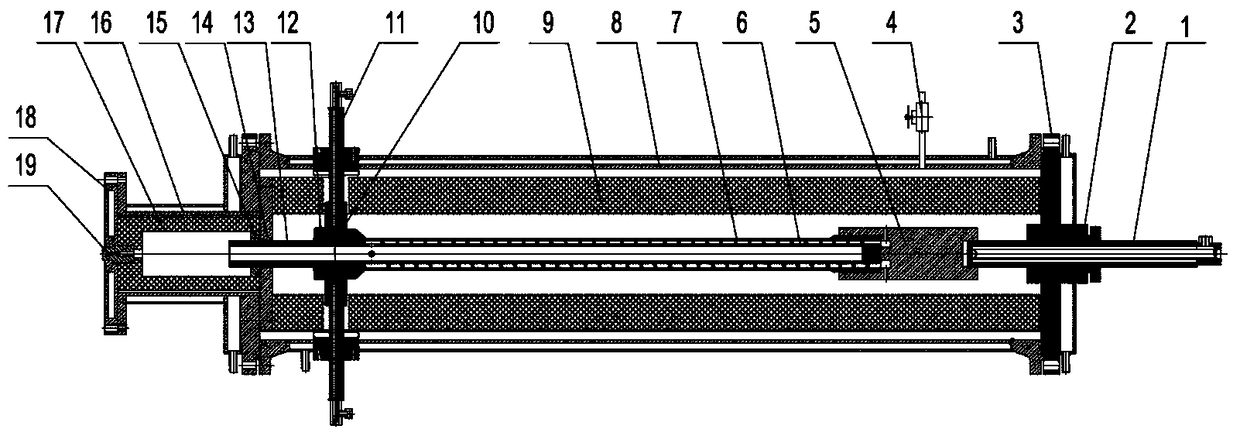

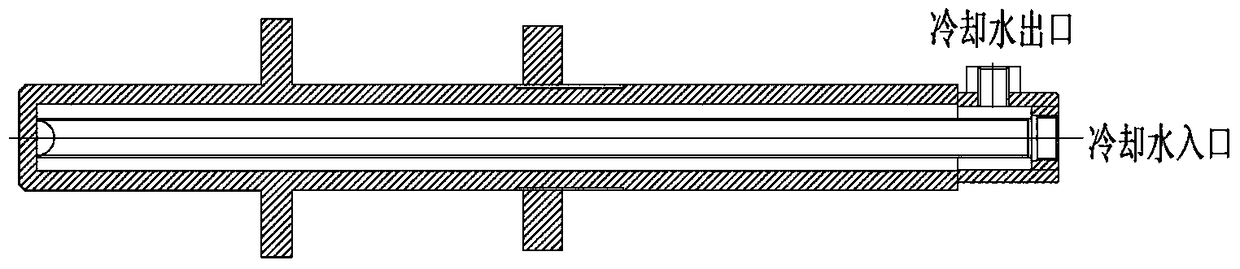

High-temperature continuous nitrogen heater

ActiveCN105627560ASolve the problem of thermal expansionSolve conductivity problemsAir heatersPower flowNitrogen

The invention provides a high-temperature continuous nitrogen heater. The high-temperature continuous nitrogen heater comprises a cylinder, a water cooling positive electrode, a water cooling negative electrode and a heating element; the heating element is mounted on the axis of the cylinder, and one end thereof is connected with the water cooling positive electrode through a slide transfer piece; the water cooling positive electrode is connected with a power supply by penetrating out of a water cooling end surface flange tightly connected to one end of the cylinder; the other end of the heating element penetrates out of a graphite baffle plate at the other end of the closed cylinder; upper and lower two water cooling negative electrodes mounted on the heating element through an electrode transfer disc are connected with the power supply after penetrating out of through holes in the wall of the cylinder; the heating element is a sandwich layer structure consisting of a graphite straight pipe on the outer layer and a graphite straight pipe with a spiral fin on the outer pipe wall on the inner layer; a spiral channel is formed between the outer-layer pipe and the inner-layer pipe through the spiral fin; and a through hole is formed in the slide transfer piece connected to one end of the heating element. The high-temperature continuous nitrogen heater solves the difficulties of thermal expansion of the heating element and high-current electric conduction, and can realize continuous heating of nitrogen currents.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

Liquid heating device

InactiveCN102679527ARealize continuous heatingImprove heating efficiencyOther heat production devicesWater heatersHeat flowEngineering

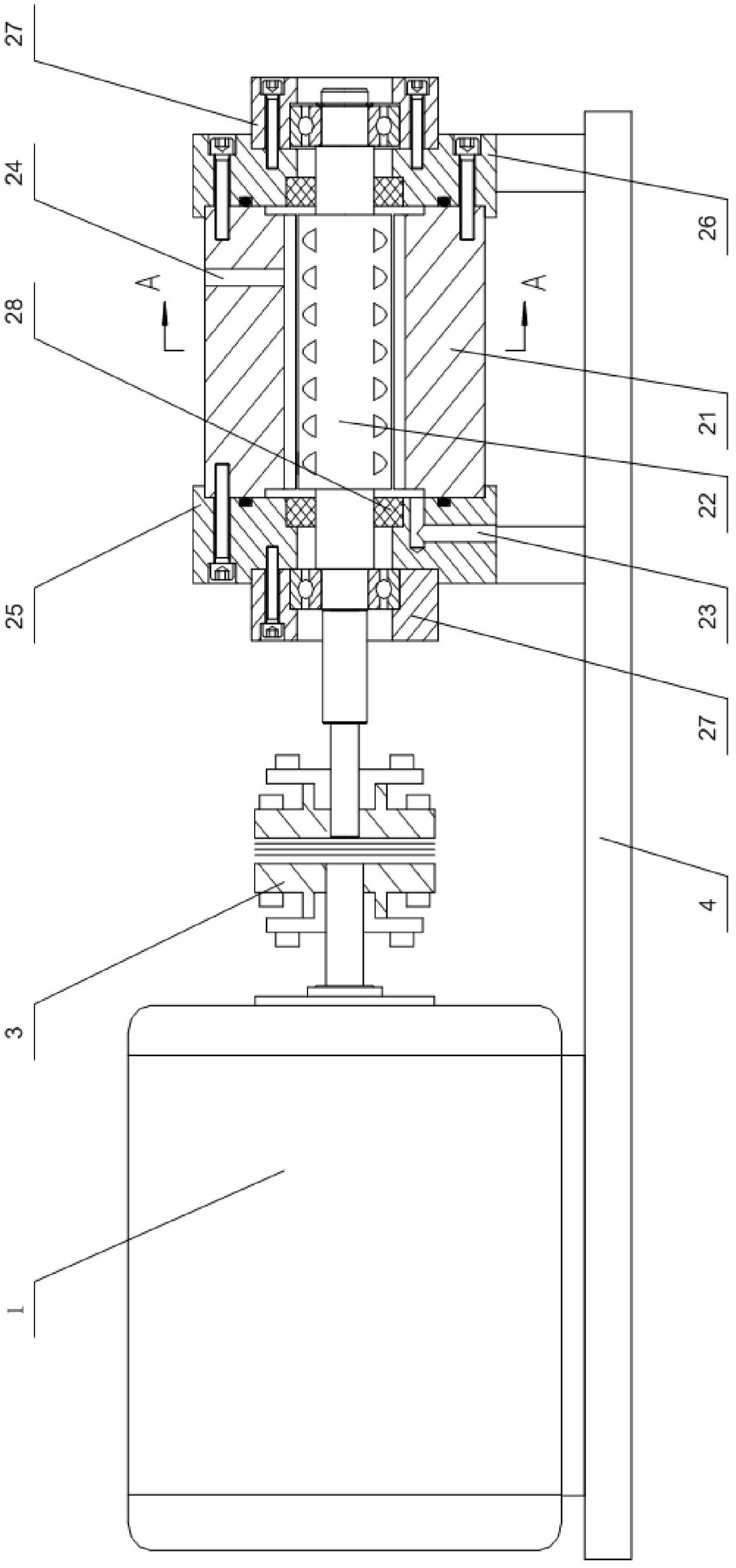

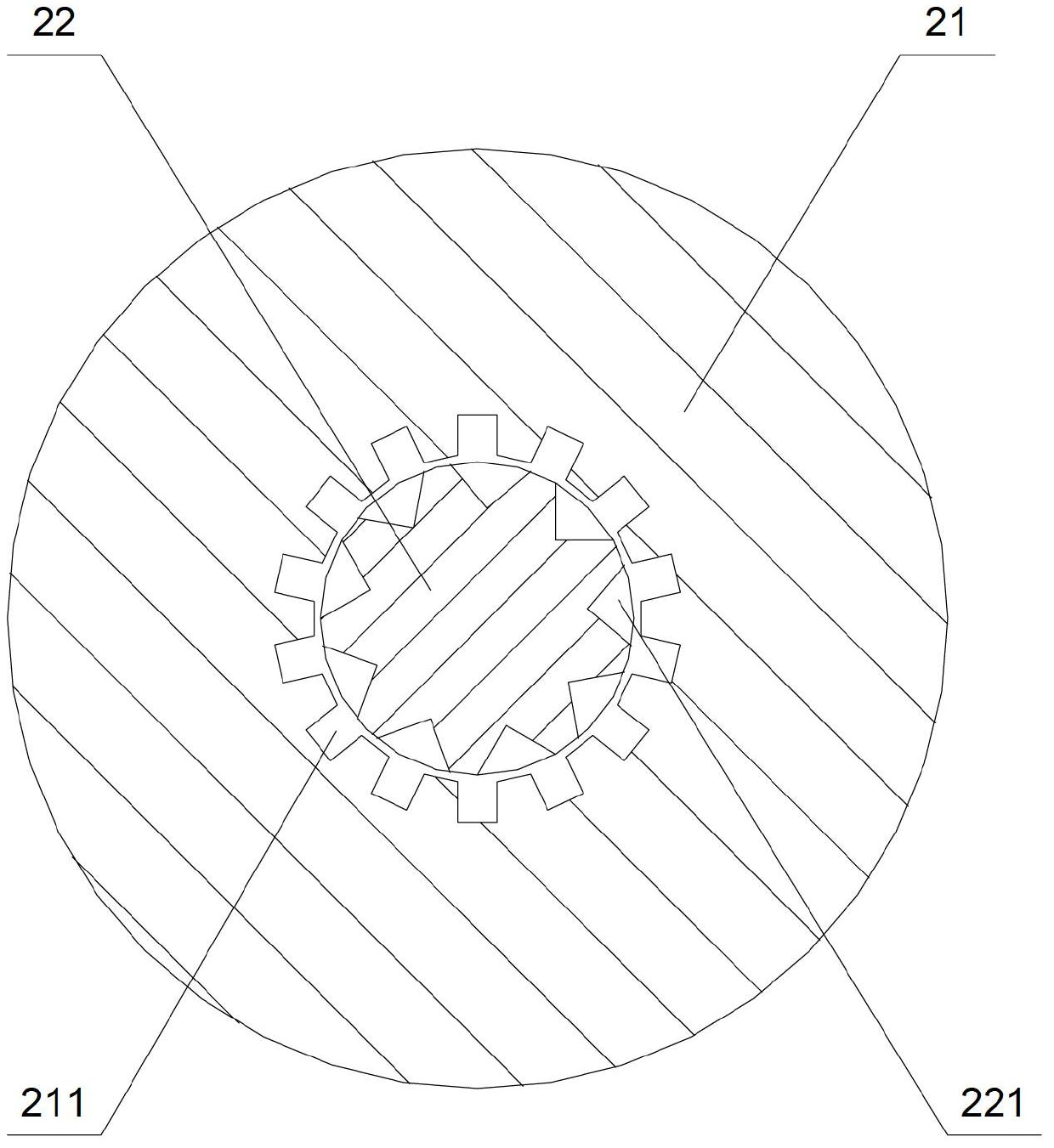

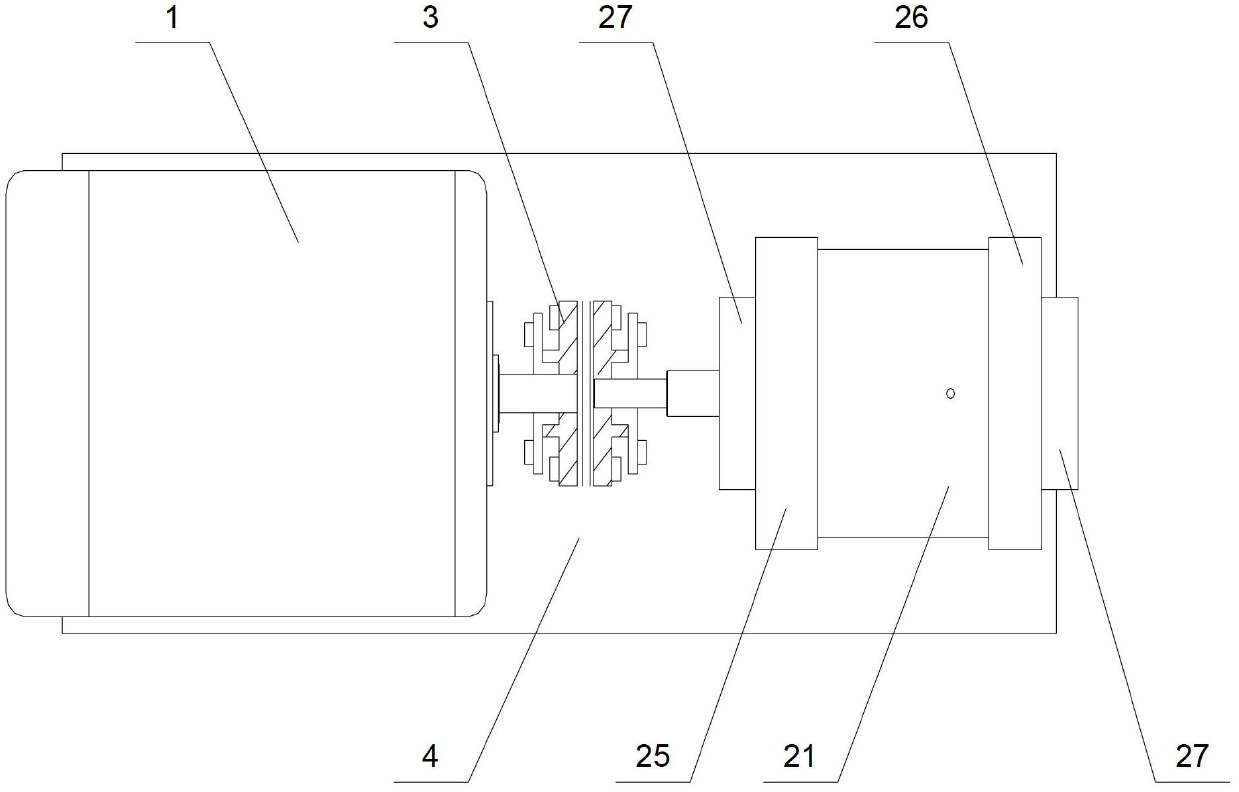

The invention discloses a liquid heating device which comprises a power source and a heating mechanism connected with the power source, wherein the heating mechanism comprises a stator, a rotor, a liquid inlet and a liquid outlet; two ends of the stator are respectively connected with a left end cover and a right end cover; the rotor is connected with the power source, and the outer edge of the cross section of the rotor is of a tooth-shaped structure, and the rotor is connected with the stator in a seal mode so as to form a heating cavity; and the liquid inlet and the liquid outlet are both communicated with the heating cavity. When the device operates, the power source drives the rotor to rotate, while the liquid to be heated flows into the heating cavity from into the liquid inlet; and because the outer edge of the cross section of the rotor is of the tooth-shaped structure, a liquid to be heated forms eddy under the stirring of the rotor, molecules in the liquid are promoted to move dramatically, the inner energy of the liquid is increased, and further the aim for heating the liquid is achieved. The liquid heating device provided by the invention implements the continuous heating of the liquid, thus the heating efficiency of the liquid is improved.

Owner:姜丽京

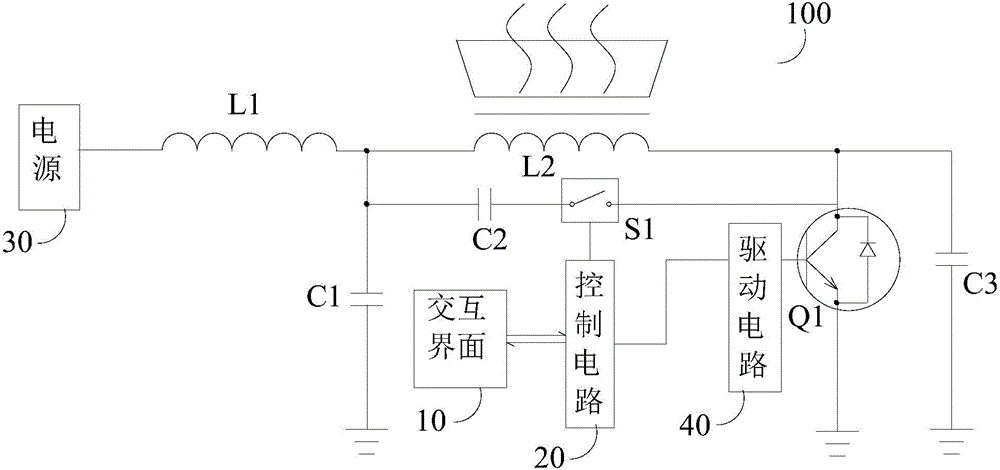

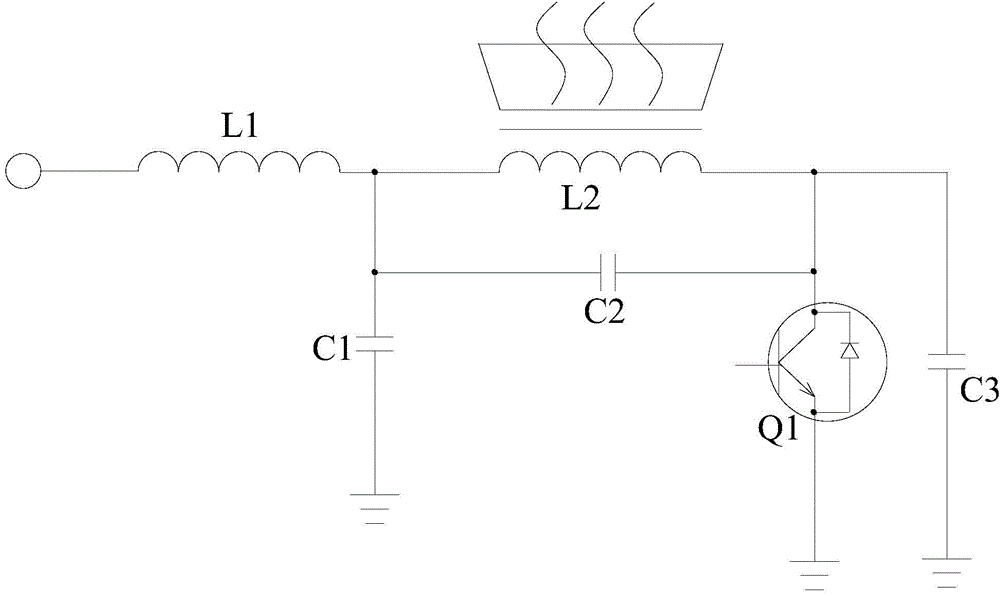

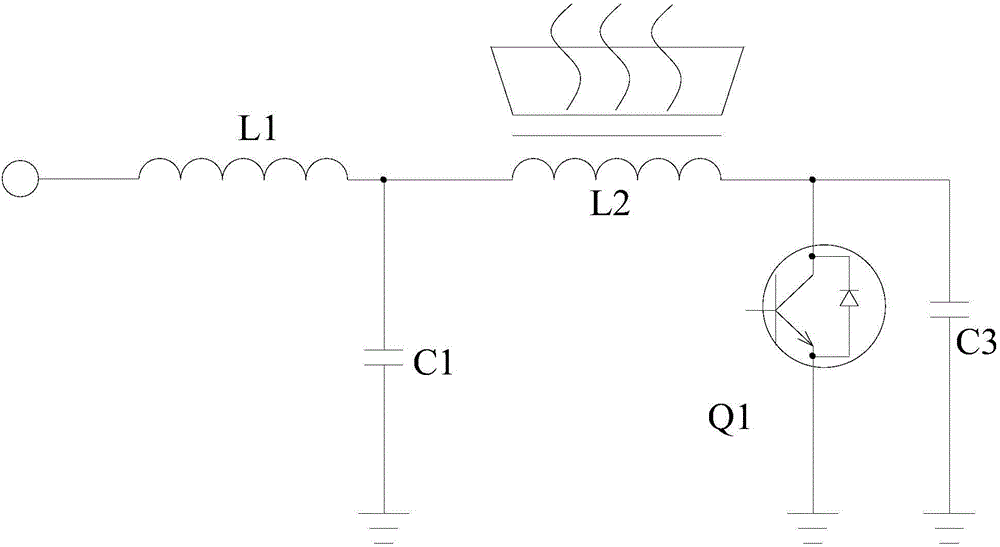

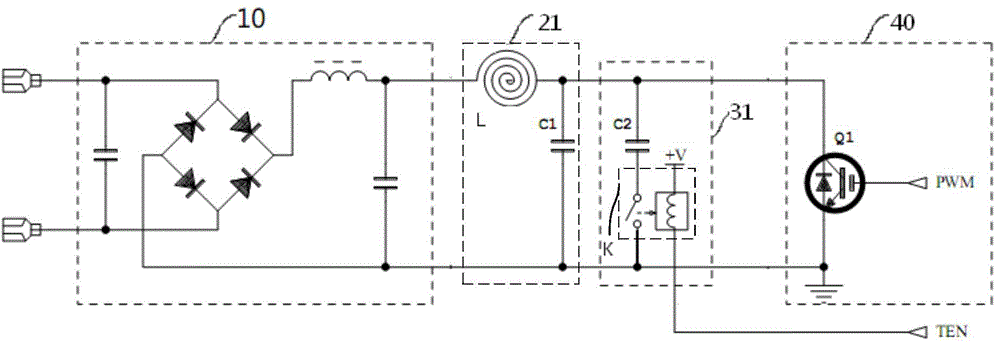

Cooking appliance and electric heating device for same

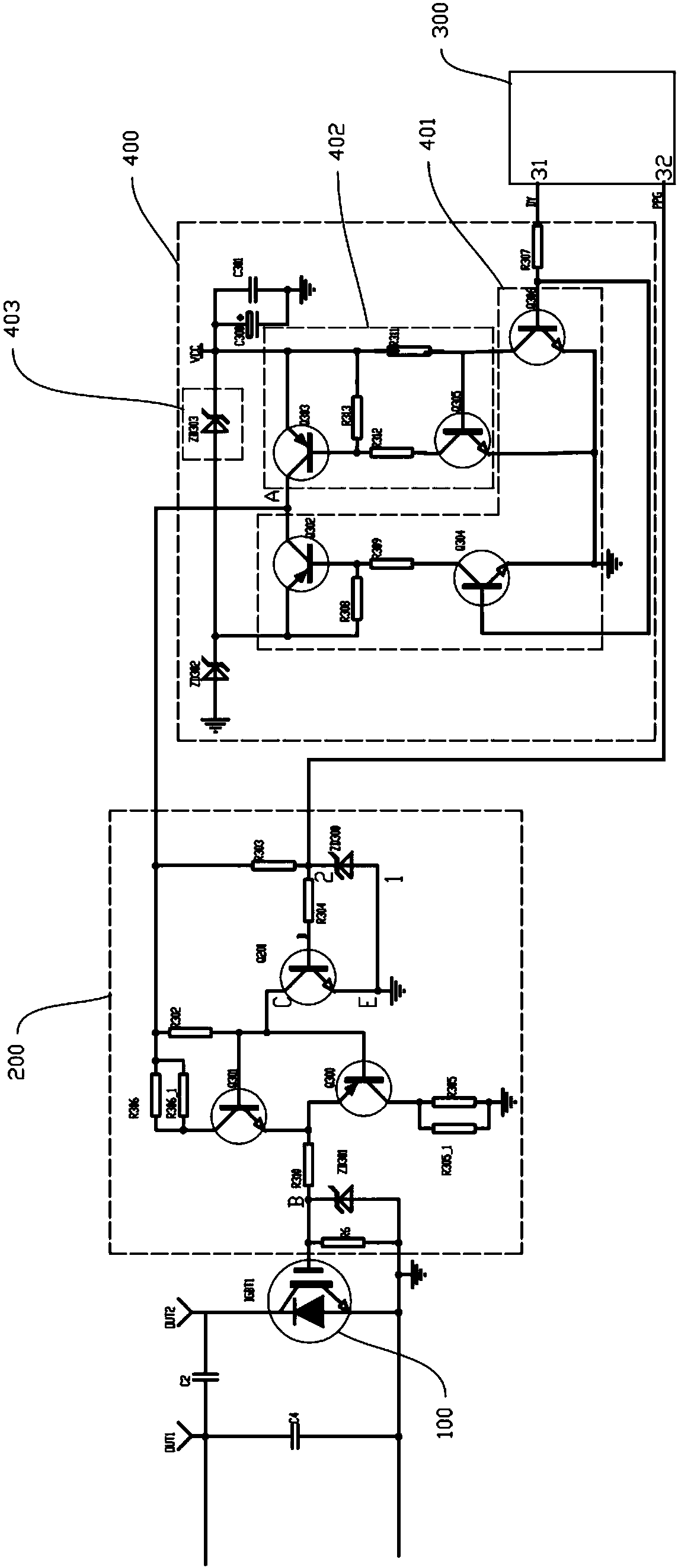

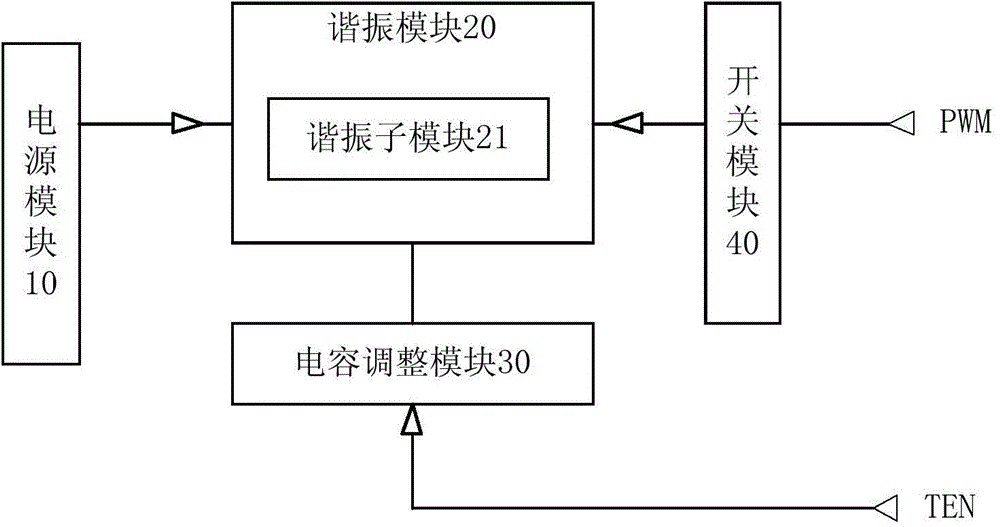

ActiveCN106136843AWide power rangeGuaranteed reliabilityDomestic stoves or rangesLighting and heating apparatusInductorCapacitance

The invention discloses a cooking appliance and an electric heating device for the cooking appliance. The electric heating device comprises an interactive interface, a first inductor, an IGBT, a resonance coil, a first capacitor, a second capacitor, a third capacitor, a switching assembly and a control circuit. The first end of the first inductor is connected with a power source, the first end of the IGBT is grounded, the first end of the resonance coil is connected with the second end of the first inductor, the second end of the resonance coil is connected with the second end of the IGBT, the first end of the first capacitor is connected with the first end of the resonance coil, the second end of the first capacitor is grounded, the first end of the second capacitor is connected with the first end of the resonance coil, the first end of the third capacitor is grounded, the second end of the third capacitor is connected with the second end of the resonance coil, the first end of the switching assembly is connected with the second end of the second capacitor, the second end of the switching assembly is connected with the second end of the third capacitor, and the control circuit is used for controlling on-off of the IGBT and the switching assembly according to user instructions, so that by changing resonance parameters of a resonance circuit, the power range of continuous heating is expanded, and user cooking experience is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

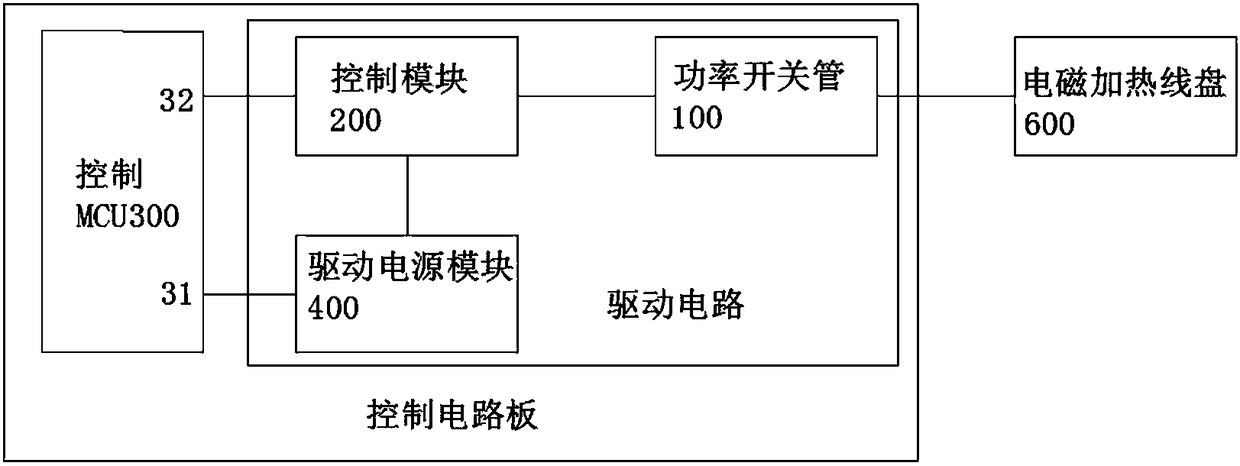

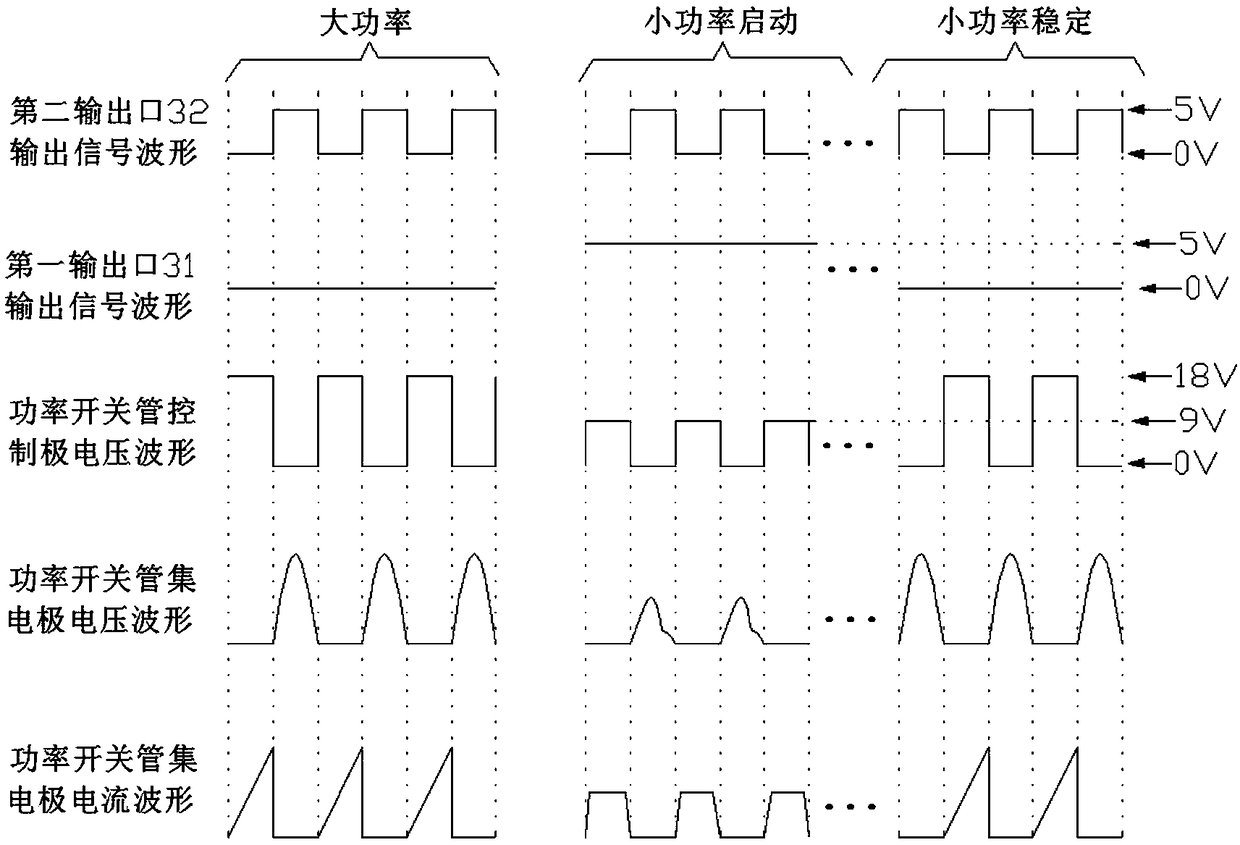

Electromagnetic heating electric cooker and cooking method thereof

InactiveCN108371471AReduce shockGreat tasteWarming devicesVessels with intergral heatingLow voltageComputer module

The invention provides an electromagnetic heating electric cooker. The electromagnetic heating electric cooker comprises a control circuit board, an electromagnetic heating spool and an inner container, the control circuit board comprises a driving circuit and a control MCU which are connected with the electromagnetic heating spool, a driving power source module is used for providing at least twodriving voltages with different voltage values for a control module, the driving voltages are used for supplying power to the control module to work, and it can be achieved that the control module drives a power switch pipe with a low voltage to work in a connected state and drives the power switch pipe with a high voltage to work in a saturated connected state; during small power heating starting, the power switch pipe is controlled in an amplified connected state, shock of a current to the power switch pipe can be reduced, working noise is lowered, the intermittent time during small power heating can be shortened, continuous heating is achieved, so that temperature is kept within a certain range, and the mouthfeel of rice is improved. The invention further provides a cooking method of the electromagnetic heating electric cooker.

Owner:JOYOUNG CO LTD

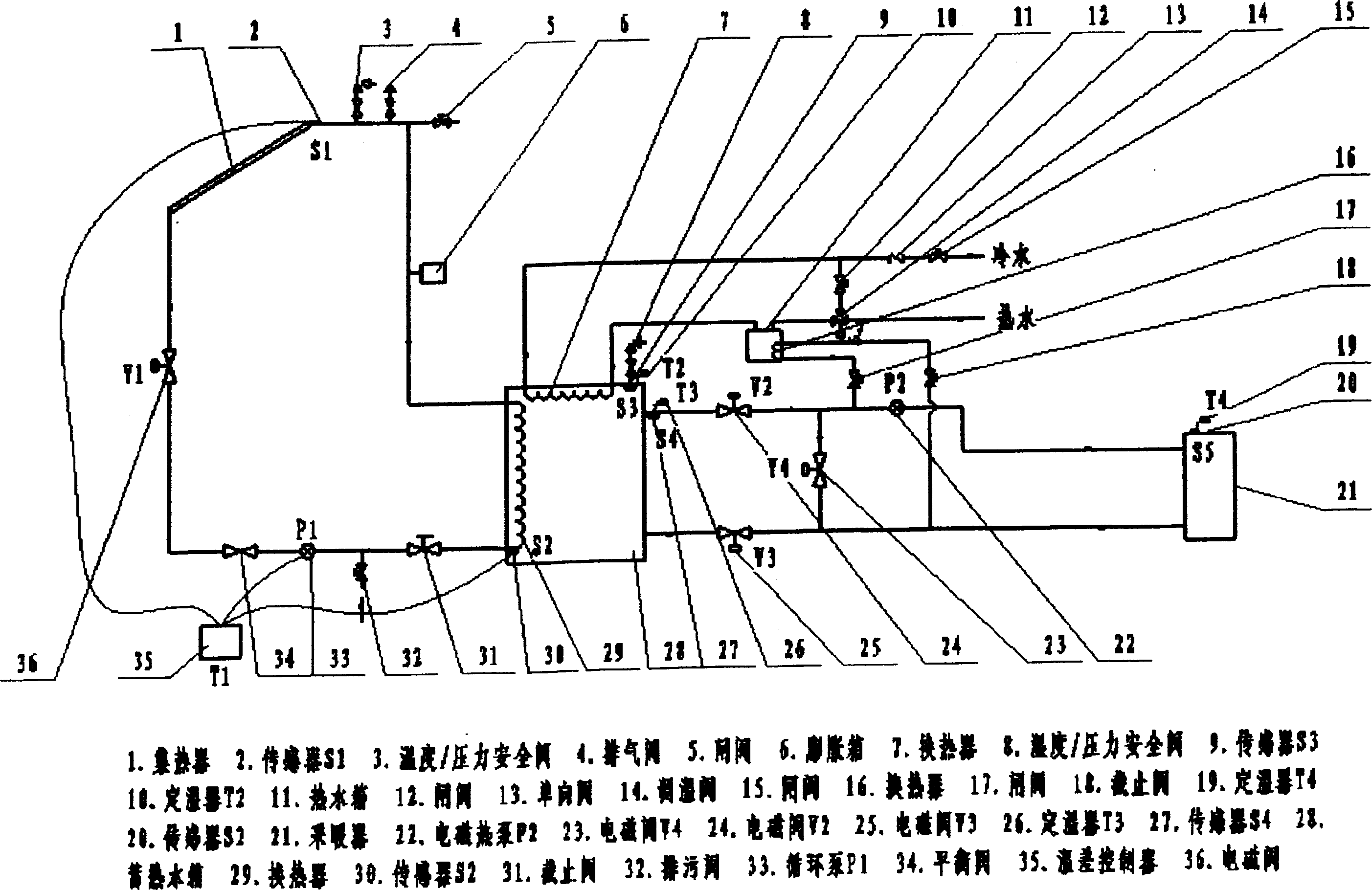

Solar electromagnetic heat pump hot-water central heating system

InactiveCN1888579AMeet heating requirementsLow running costSolar heat devicesEnergy efficient heating/coolingEngineeringHeating temperature

A solar electromagnetic heat pump hot water heating system consists of a solar heat collector, an electromagnetic heat pump, hot water storage tank, a sensor, a hot water tank, a heat exchanger, a circulating pump, a magnetic valve, a thermoelectric controller, a heating controller and a heating equipment. When the heat absorbed by the heat collector is enough to make the system run and the heating is needed in the room, the heating controller starts the electromagnetic heat pump to circulate the hot water in the hot-water storage tank to the heating equipment for heating in the room. When the heat absorbed by the heat collector is not enough to make the system run, but the heating is needed in the room, the electromagnetic heat pump is used for raising the water temperature of the system to the designed heating temperature and then it is circulated to the heating equipment for heating in the room.

Owner:唐晓江

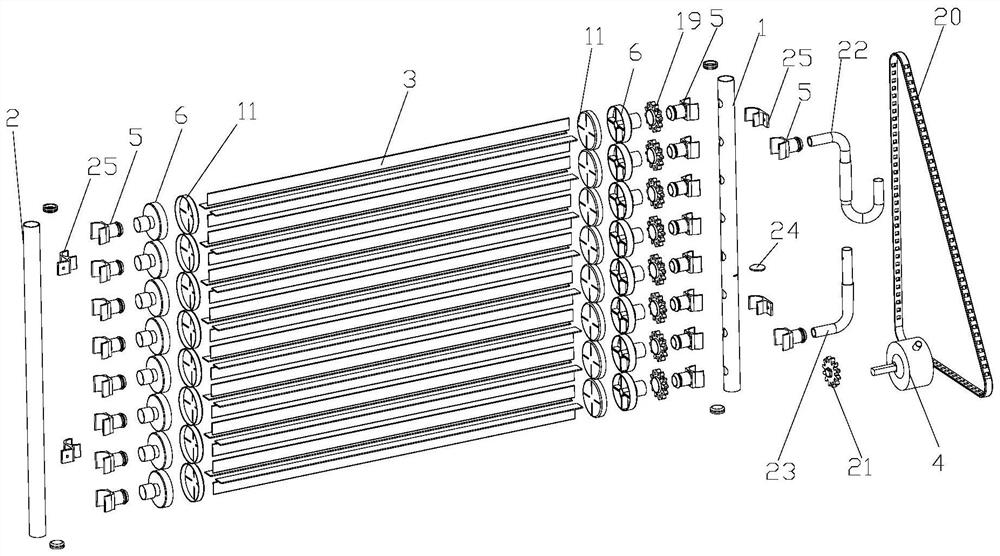

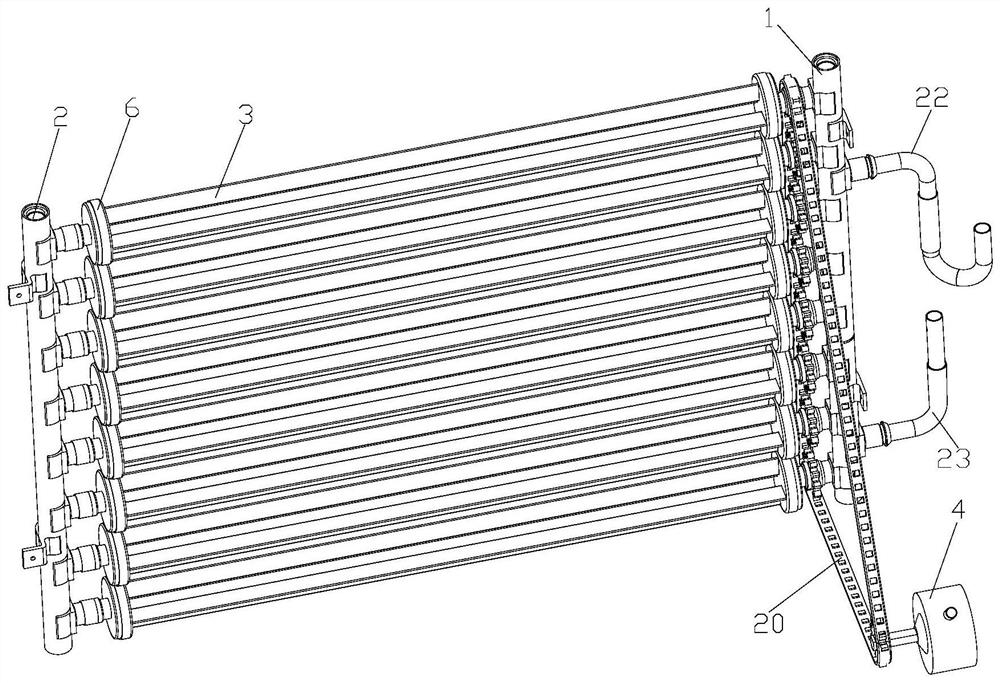

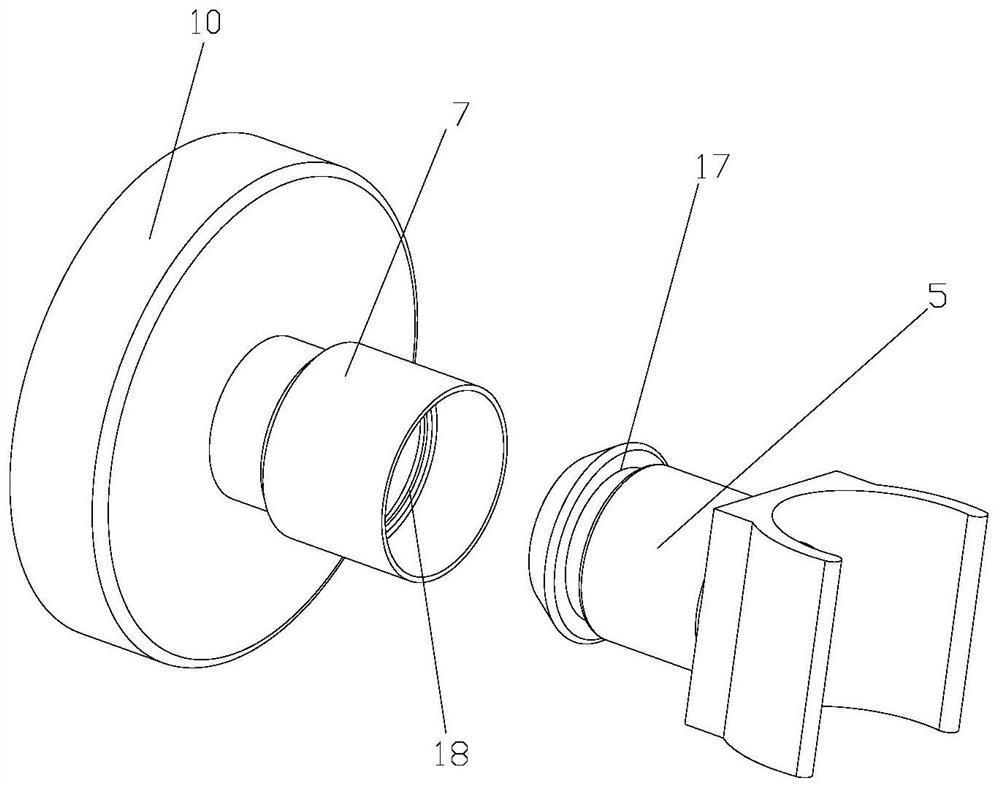

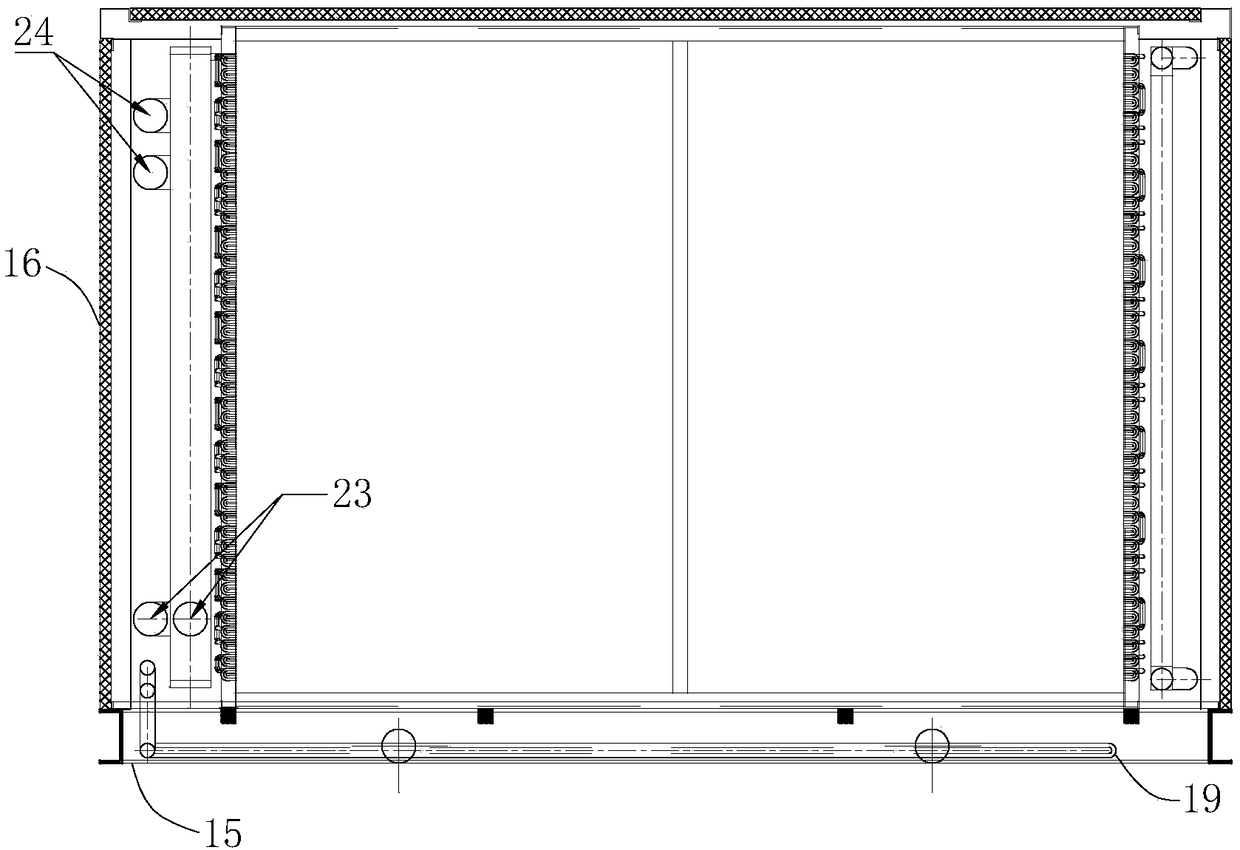

Micro-channel heat exchanger and heat pump system

PendingCN111878908ADrain fastImprove circulation rateHeat pumpsCondensate preventionEngineeringMechanical engineering

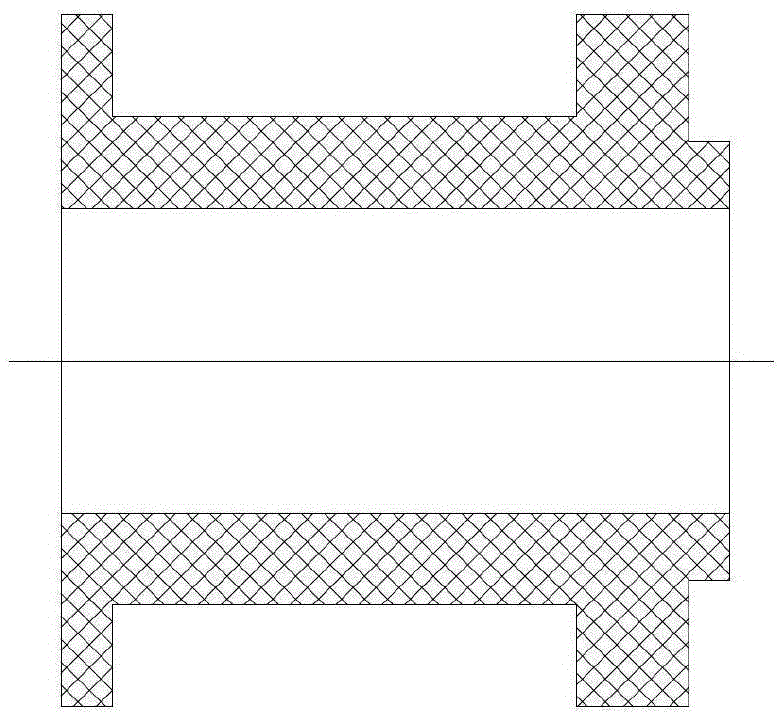

The invention provides a micro-channel heat exchanger and a heat pump system. The micro-channel heat exchanger comprises a first collecting pipe (1), a second collecting pipe (2), rotary connecting assemblies and a flat pipe (3), the first end of the flat pipe (3) communicates with the first collecting pipe (1), the second end of the flat pipe (3) communicates with the second collecting pipe (2),and the first end of the flat pipe (3) can be rotatably connected with the first collecting pipe (1) through the rotary connecting assembly; and the second end of the flat pipe (3) can be rotatably connected with the second collecting pipe (2) through the rotary connecting assembly. According to the micro-channel heat exchanger, a water bridge between the flat pipe and fins can be damaged, condensate water can be rapidly discharged, the circulation rate of air is increased, and the heat exchange efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

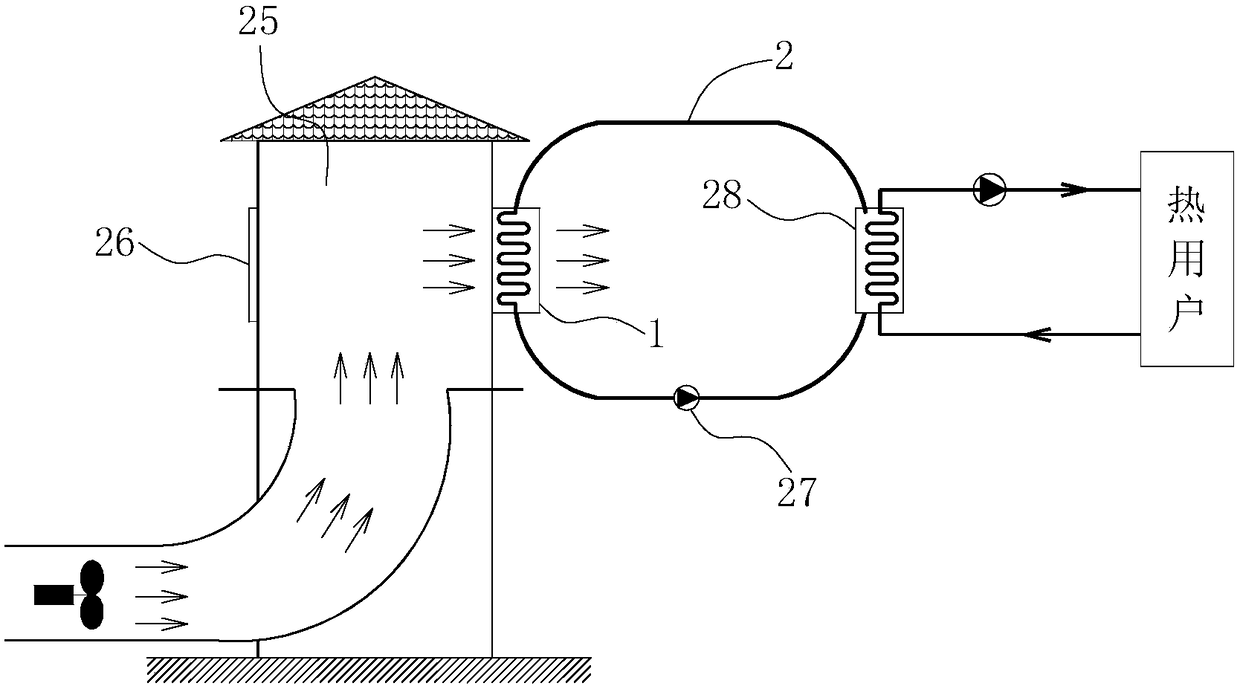

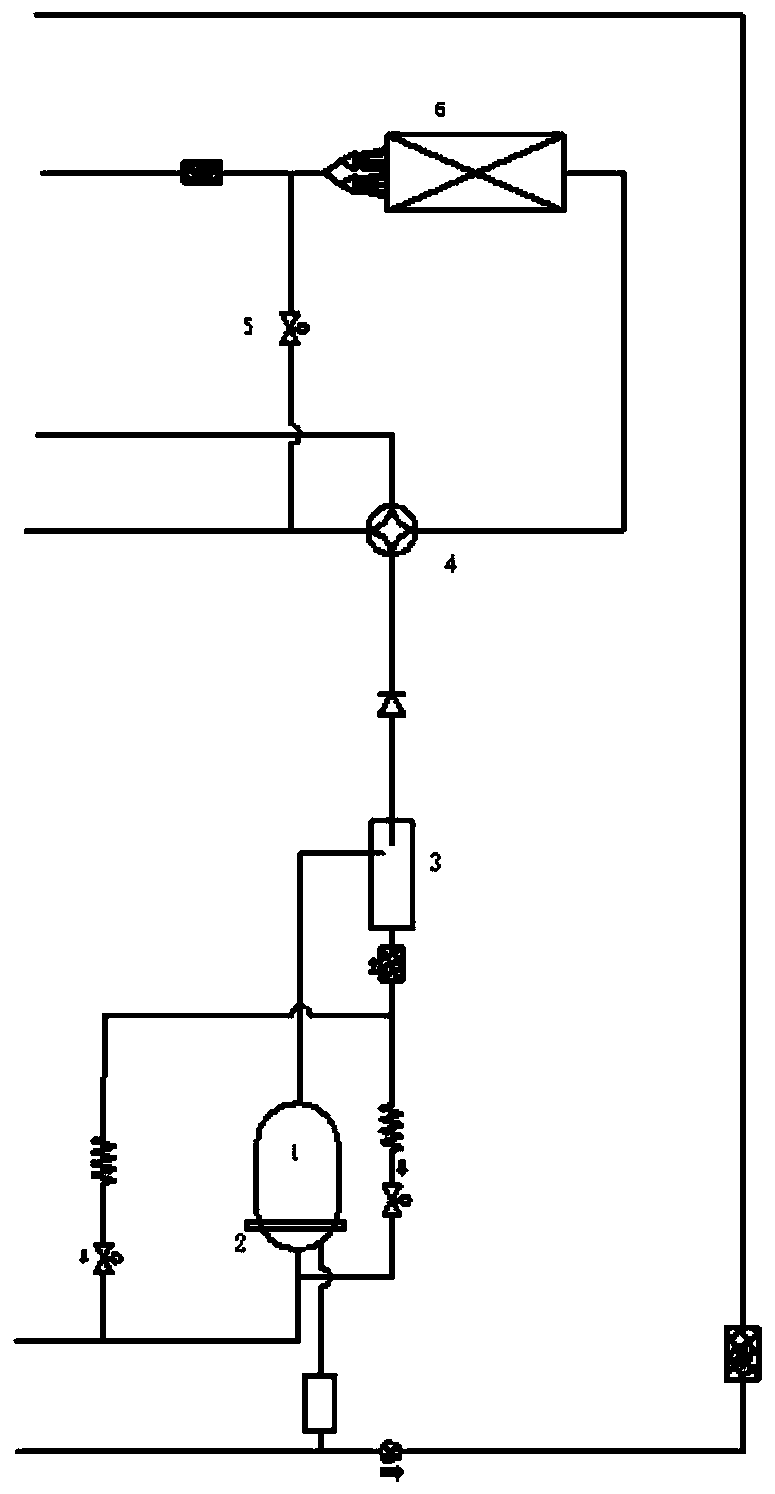

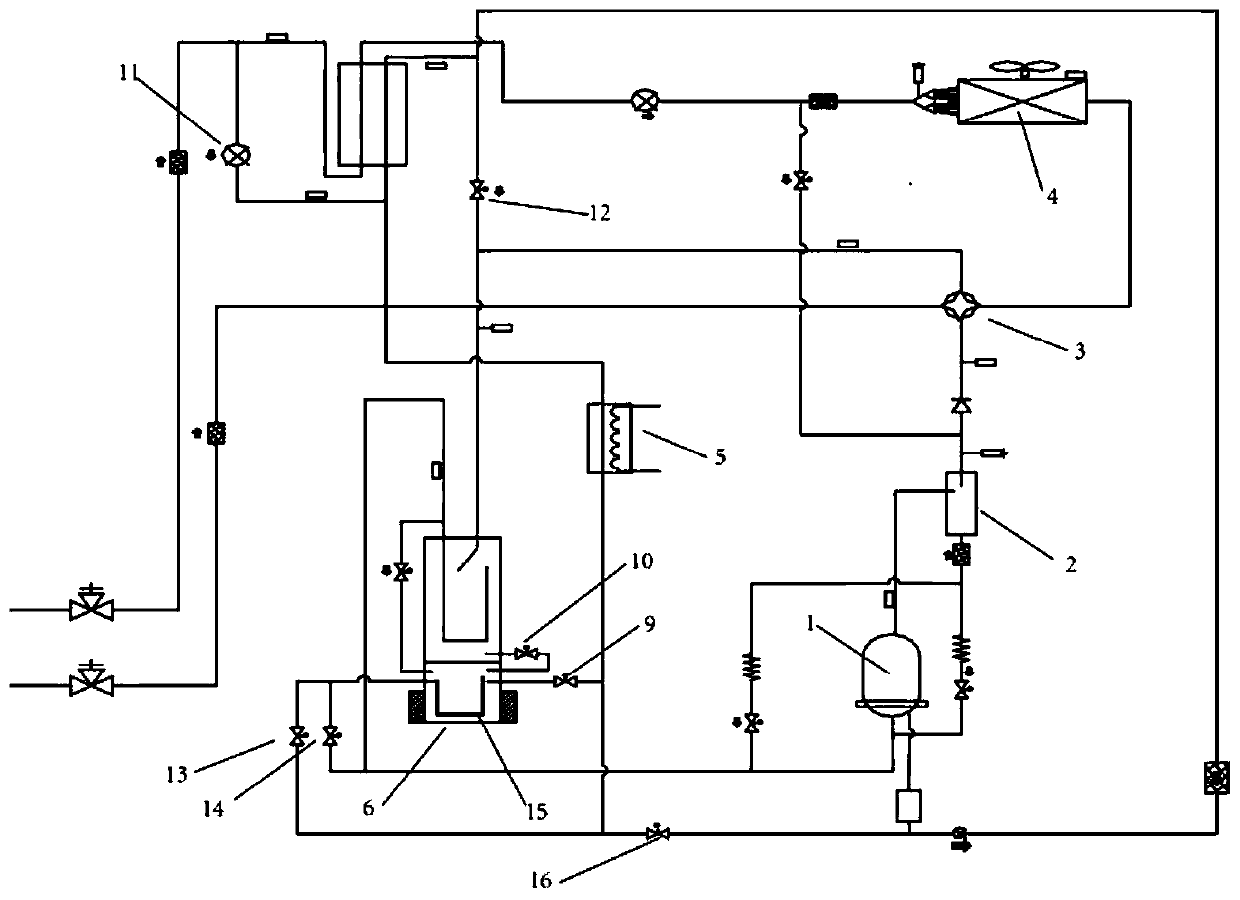

Air source heat pump unit capable of realizing continuous heat supply

PendingCN108362040AImprove running stabilityImprove energy efficiencyMechanical apparatusHeat pumpsPlate heat exchangerEngineering

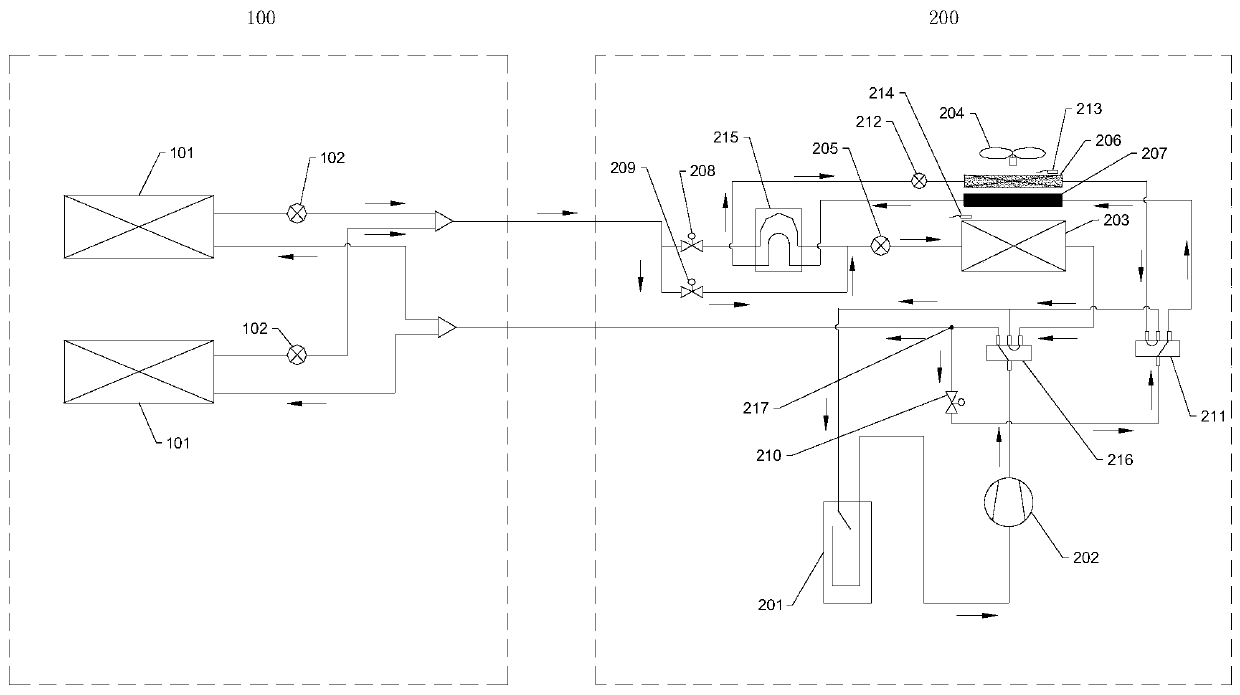

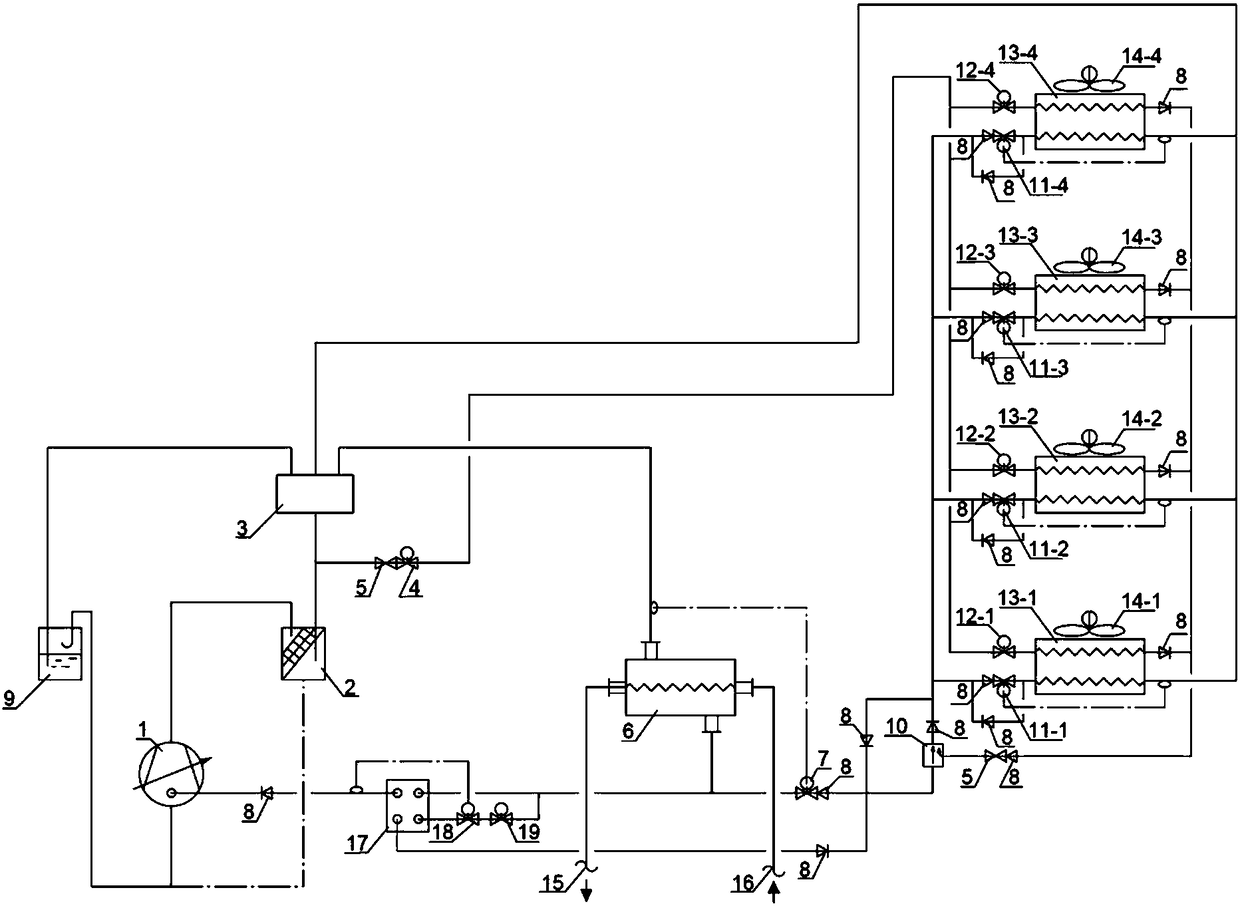

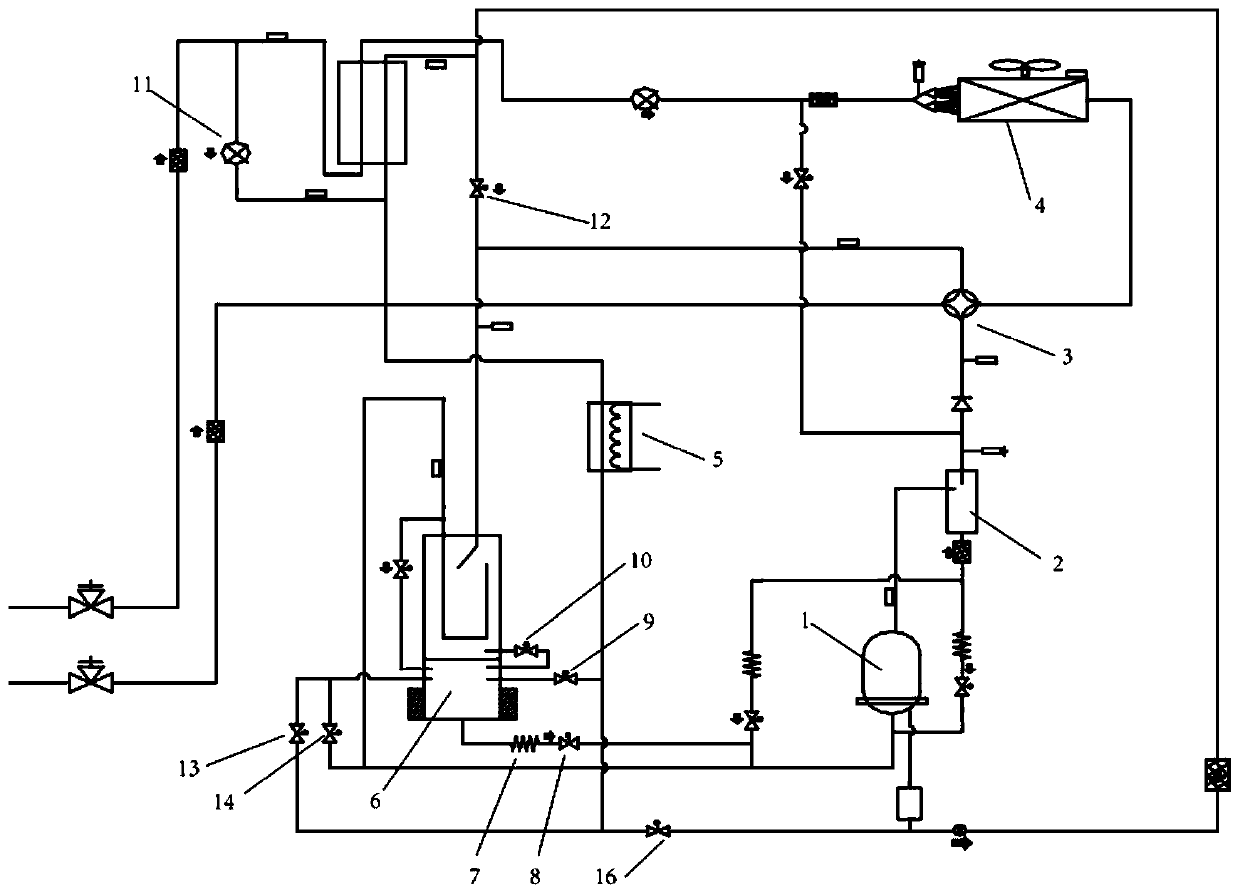

The invention relates to an air source heat pump unit capable of realizing continuous heat supply. The air source heat pump unit comprises a compressor unit, an indoor water heat exchange unit, a quasi-second-stage compression unit, an outdoor air heat exchange unit and a defrosting branch unit. According to the air source heat pump unit disclosed by the invention, the new technical scheme of quasi-second-stage compression, water-side double-stage heat exchange, and multi-branch heat taking and alternating defrosting, of an air source heat pump under the working condition of low environment temperature is adopted, firstly, a compressor is additionally provided with an air supplementing port, and a middle plate heat exchanger is additionally arranged in a system, so as to form heat pump circulation with the quasi-second-stage compression; secondly, double-stage heat exchange is adopted for the indoor water heat exchange unit, and two stages of heat exchangers are arranged, so as to furthest increase the temperature of circulating water, and the temperatures of supply and return water; and finally, an outdoor air heat exchanger of the air source heat pump is configured to be at leasttwo branched heat taking and defrosting systems capable of independently running, and defrosting operation is carried out on a fluorine-air heat exchange mechanism in each branch in an alternating manner one by one, so that alternating accurate defrosting and continuous heat supply are realized.

Owner:卡林热泵技术有限公司

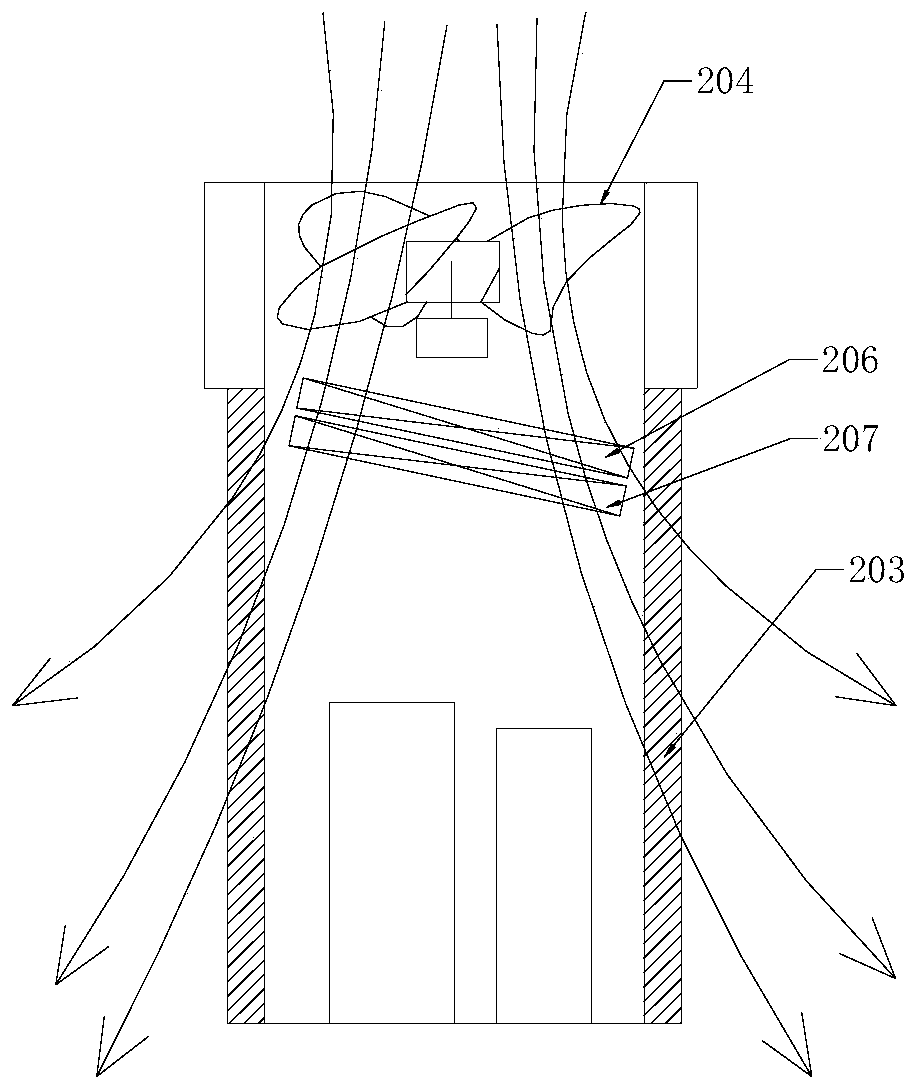

Air conditioning system with defrosting device and control method thereof

ActiveCN110411055AReduces chances of frostingRealize continuous heatingMechanical apparatusCorrosion preventionEngineeringHigh pressure

The invention provides an air conditioning system with a defrosting device and a control method thereof, and relates to the technical field of air conditioners. The air conditioner solves the technical problem that an existing air source heat pump air conditioning system indoor unit does not generate heat in a defrosting mode. The air conditioning system comprises an indoor unit and an outdoor unit, wherein the outdoor unit comprises a dehumidification heating heat exchanger, the dehumidification heating heat exchanger is located in a defrosting branch, and the defrosting branch is connected with a heating main loop in parallel; and the dehumidification heating heat exchanger is located on an air circulation path between an outdoor fan and an outdoor unit heat exchanger. A part of high-temperature and high-pressure refrigerants led out of the heating main loop enters the dehumidifying heating heat exchanger in the defrosting branch to carry out dehumidification and heating on air before entering the outdoor unit heat exchanger, so that the possibility of frosting of the outdoor unit heat exchanger is greatly reduced, continuous heating is realized, and the user experience in winterheating operation is improved.

Owner:GREE ELECTRIC APPLIANCES INC

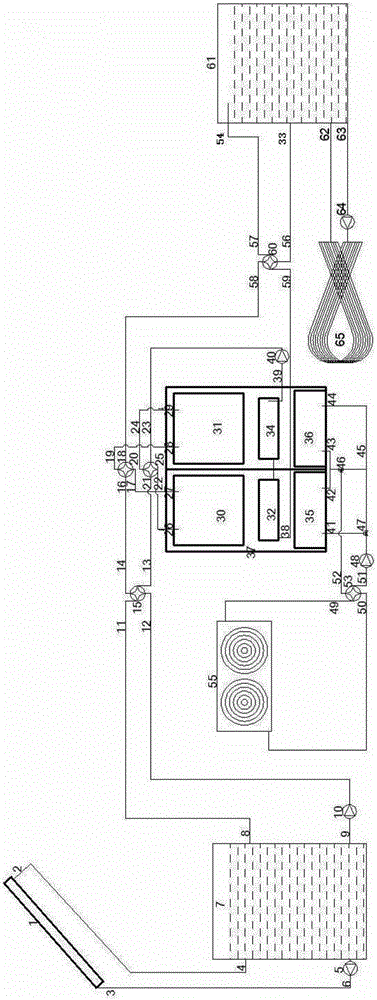

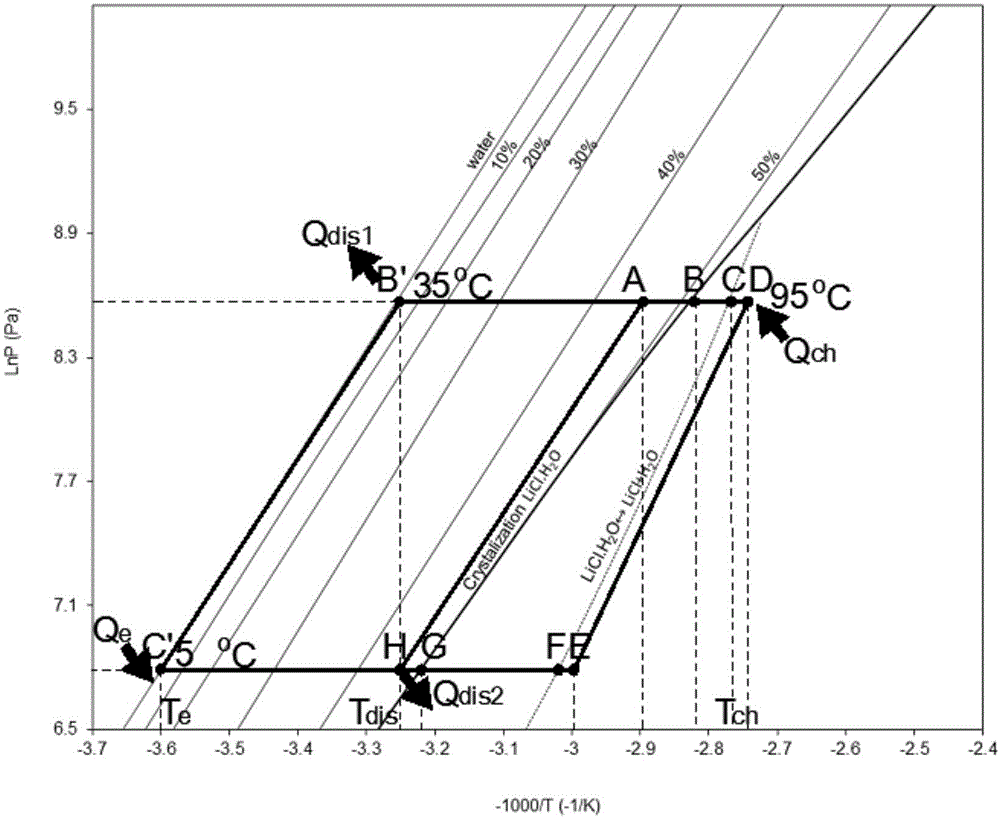

Solar-powered efficient moisture absorption-thermochemical reaction heat pump system

InactiveCN104089431AImprove cycle moisture absorptionImprove energy flowMechanical apparatusClimate change adaptationCyclic processMoisture absorption

The invention relates to a solar-powered efficient moisture absorption-thermochemical reaction heat pump system. The solar-powered efficient moisture absorption-thermochemical reaction heat pump system comprises a solar heat collector (1), a hot water tank (7), an absorption-thermochemistry heat pump set (37), an evaporator (55), a heat supply tank (61) and a heating pipe (65). The absorption-thermochemistry heat pump set comprises a left absorption bed (30), a left condenser (32), a left evaporator (35), a right absorption bed (31), a right condenser (34) and a right evaporator (36). A circulation process comprises the steps of absorption of moisture absorption salt, crystalalization of the moisture absorption salt and a thermochemical reaction. Compared with the prior art, the solar-powered efficient moisture absorption-thermochemical reaction heat pump system can realize continuous heat supply and built-in type energy storage, heat supply is conducted only when needed, and built-in type energy storage and heat supply can be realized without additionally arranging an external auxiliary energy storage device; in the energy storage process, the working medium salt and refrigerant are mutually isolated, and loss is barely caused.

Owner:SHANGHAI JIAO TONG UNIV

Defrosting group control method for direct-cooling type deep-enthalpy heat removal air return heat pump system

ActiveCN108151367ARealize continuous heatingContinuous defrostingMechanical apparatusHeat pumpsFrostNuclear engineering

The invention discloses a defrosting group control method for a direct-cooling type deep-enthalpy heat removal air return heat pump system. The defrosting group control method comprises the followingsteps that a heat removal valve F<heat removal> on a heat removal heat exchanger is closed, and heat removal is stopped; a defrosting valve F<defrosting> on a defrosting heating pipe is opened, aftera period of set time defrosting is conducted, the defrosting valve F<defrosting> is closed, and defrosting is stopped; the air return pressure difference value between an air inlet end and an air outlet end of an air return heat removal box is measured and calculated; and when the air return pressure difference value is greater than a set value, a spraying valve F<spraying> is opened, the outer surface of the heat removal heat exchanger is cleaned, otherwise, the heat removal valve F<heat removal> is opened for heat removal. The defrosting group control method for the direct-cooling type deep-enthalpy heat removal air return heat pump system can smoothly remove frost on the surface of the air return heat removal box.

Owner:BEIJING ZHONGKUANG BONENG ENERGY SAVING SCI &TECH

Electric vehicle air conditioning system, electric vehicle and control method for electric vehicle air conditioning system

ActiveCN106042827BRealize continuous heatingImprove comfortAir-treating devicesVehicle heating/cooling devicesFour-way valvePlate heat exchanger

The invention provides an electric automobile air conditioning system which comprises a compressor, a four-way valve, an extra-automobile heat exchanger, a first intra-automobile heat exchanger, a second intra-automobile heat exchanger, a first pipeline, a second pipeline, a third pipeline, a fourth pipeline, a first control valve and a second control valve. When the extra-automobile heat exchanger needs to be used for defrosting, a first end opening of the four-way valve communicates with a fourth end opening, a second end opening communicates with a third end opening, and a second branch communicates with the first pipeline and the second pipeline; and the first control valve controls the third pipeline to be connected, the second control valve controls the fourth pipeline to be connected, and a first branch is disconnected from the first pipeline and the second pipeline. The invention further provides an electric automobile and a control method of the electric automobile air conditioning system. By the adoption of the electric automobile air conditioning system, the electric automobile and the control method of the electric automobile air conditioning system, continuous heating in the automobile can be achieved in the defrosting process of the extra-automobile heat exchanger, and the comfort in the automobile is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

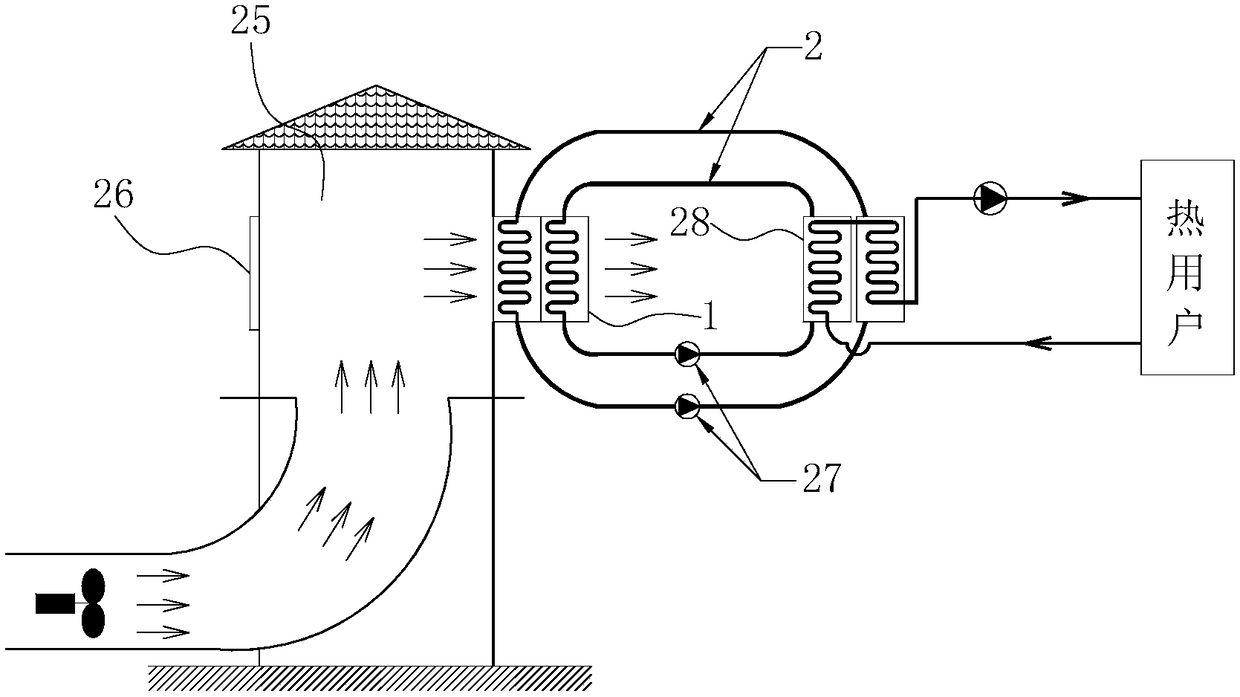

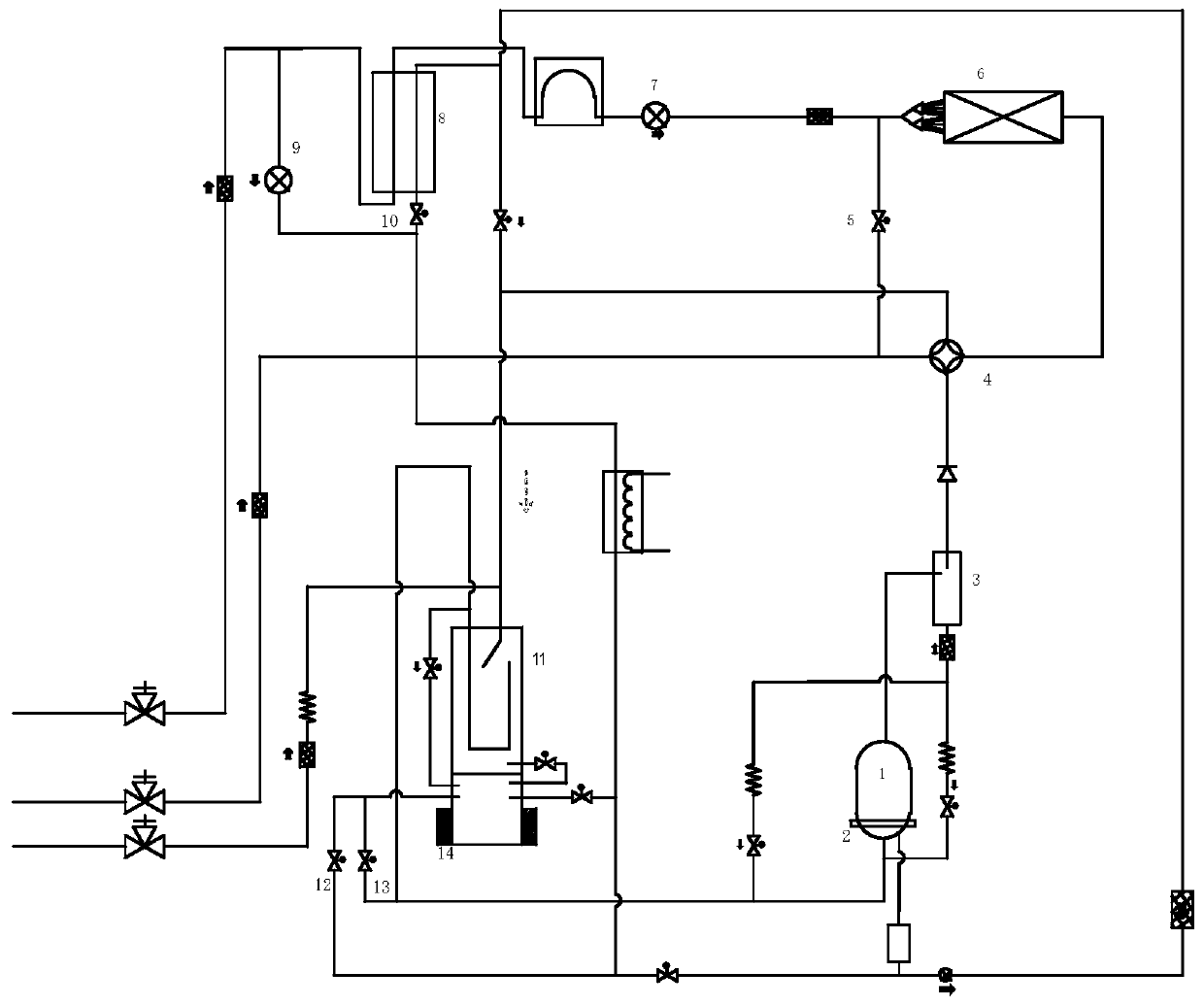

Air source heat pump unit in continuous heat supplying

PendingCN108387033AIncreased operational stability and energy efficiencyWide range of applicationsMechanical apparatusHeat pumpsEngineeringAir source heat pumps

The invention relates to an air source heat pump unit in continuous heat supplying. The air source heat pump unit in continuous heat supplying comprises a compressor unit, an indoor water heat exchanging unit, a quasi-second level compression unit, an outdoor air heat exchanging unit and a defrosting branch circuit unit; due to the comprehensive technical scheme with quasi-second level compressioncombined with the temporal and spatial segmentation principle, on one hand, a compressor is additionally provided with a gas supplementing port, and a middle plate type heat exchanger is additionallyarranged in the system so that a quasi-second level compression heat pump cycle can be formed; and on the other hand, an air source heat pump outdoor air heat exchanger is arranged into at least twobranch circuit heat taking and defrosting systems capable of independently running, a fluorine-air heat exchanging mechanism in each branch circuit is subjected to defrosting operation in turns one byone, and therefore in-turn accurate defrosting and continuous heat supplying are achieved.

Owner:卡林热泵技术有限公司

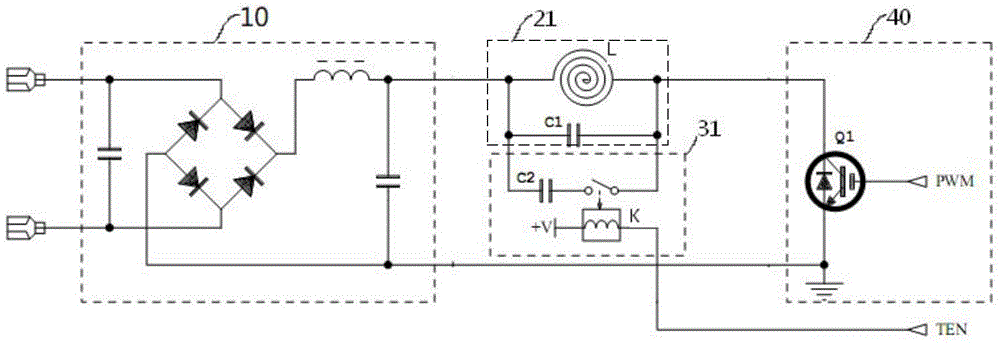

Electromagnetic heating apparatus and electromagnetic oven equipped with same

InactiveCN106162971AImprove satisfactionRealize continuous heatingInduction heating controlCapacitanceResonance

The invention discloses an electromagnetic heating apparatus and an electromagnetic oven. The electromagnetic heating apparatus comprises a power supply module, a resonance module, a capacitance adjustment module, and a switch module, wherein the resonance module is connected with the power supply module; the resonance module is provided with a resonance sub module which consists of a resonance inductor and a resonance capacitor; the capacitance adjustment module is used for adjusting the capacitance value of the resonance capacitor in the resonance module; and the switch module is connected with the resonance module. By virtue of the additionally-provided capacitance adjustment module, the electromagnetic heating apparatus can realize continuous heating when the output power is kept within a certain frequency range (such as 200-2,000W); compared with the prior art, the low-power continuous heating purpose of the electromagnetic heating apparatus is fulfilled; the food cooking effect is remarkably improved; and the degree of satisfaction of users is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

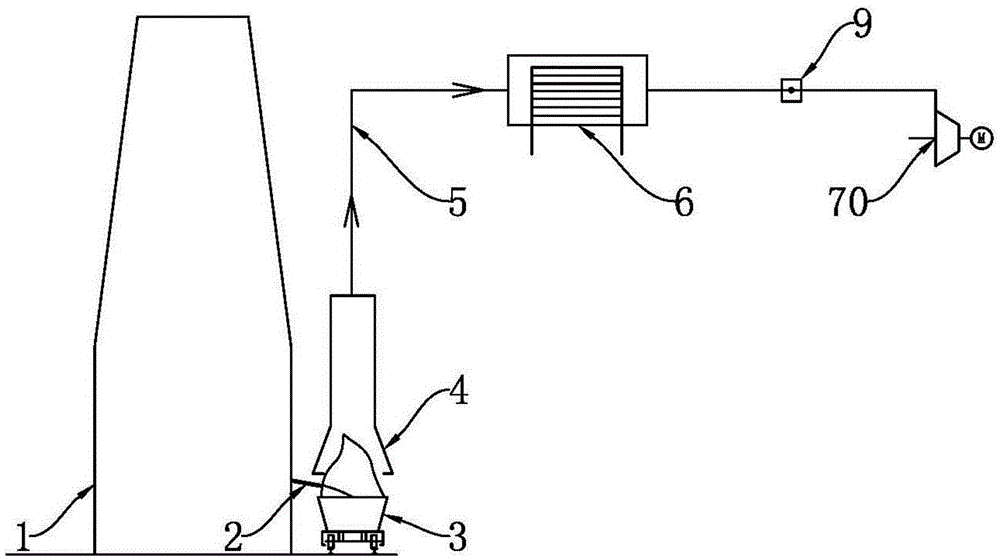

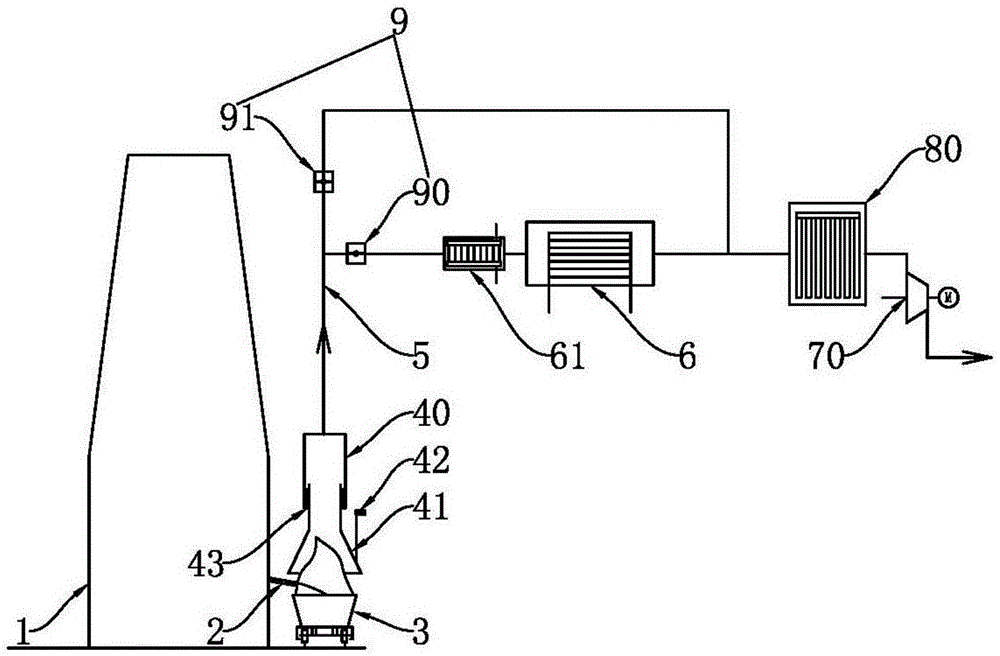

Itinerant recovery system and method for sensible heat of discharged liquid calcium carbide

ActiveCN105571339AAchieve energy saving and emission reductionEliminate pollutionWaste heat treatmentFree coolingMaterials science

The invention provides an itinerant recovery system and method for sensible heat of discharged liquid calcium carbide. The system comprises a calcium carbide furnace, a launder and a calcium carbide pot; and one end of the launder is connected with a liquid outlet of the calcium carbide furnace, and the other end of the launder extends to the position above the calcium carbide pot. A fan housing is arranged over the calcium carbide pot; the upper end of the fan housing is connected with an inlet of an air hose; an outlet of the air hose is connected with heat using equipment; and the heat using equipment is connected with a draft fan. The air hose is provided with a recovery valve. According to the itinerant recovery system and method for the sensible heat of the discharged liquid calcium carbide, heat exchange is conducted with the flowing calcium carbide through induced air, heat of liquid calcium carbide flow is absorbed, and other substances are heated through the induced air with the temperature raised. By means of the system and method, the sensible heat, with the temperature being 1000 DEG C or above, of the calcium carbide can be recovered without changing the existing production process, or increasing the number of calcium carbide pots, or increasing the plant area or increasing production equipment or devices, and the recovered heat accounts for approximately 50% of the whole sensible heat of the calcium carbide, so that significant energy conservation and emission reduction are achieved. Compared with natural cooling, by means of system and method, cooling time of the calcium carbide is greatly shortened, and calcium carbide production efficiency is improved.

Owner:北京天蓝华兴能源科技有限公司

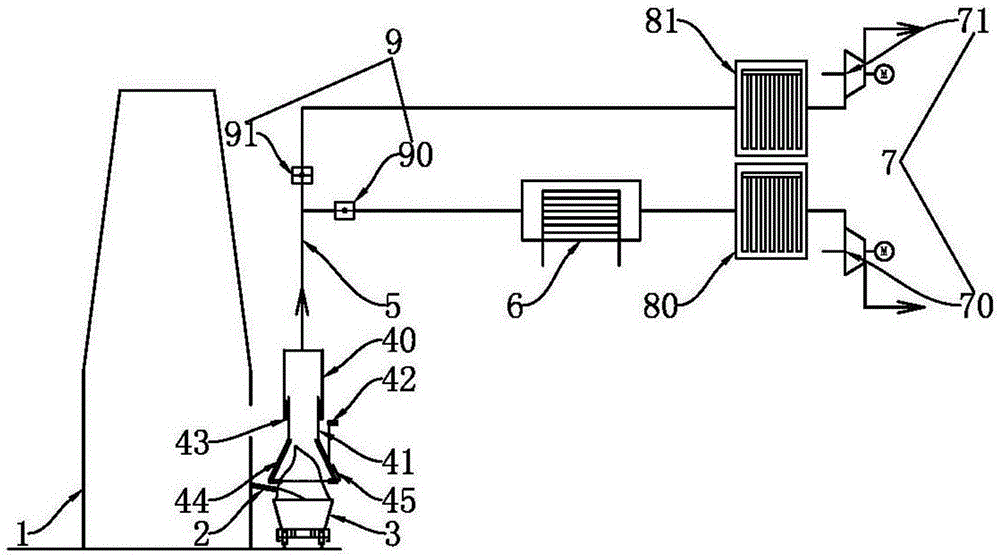

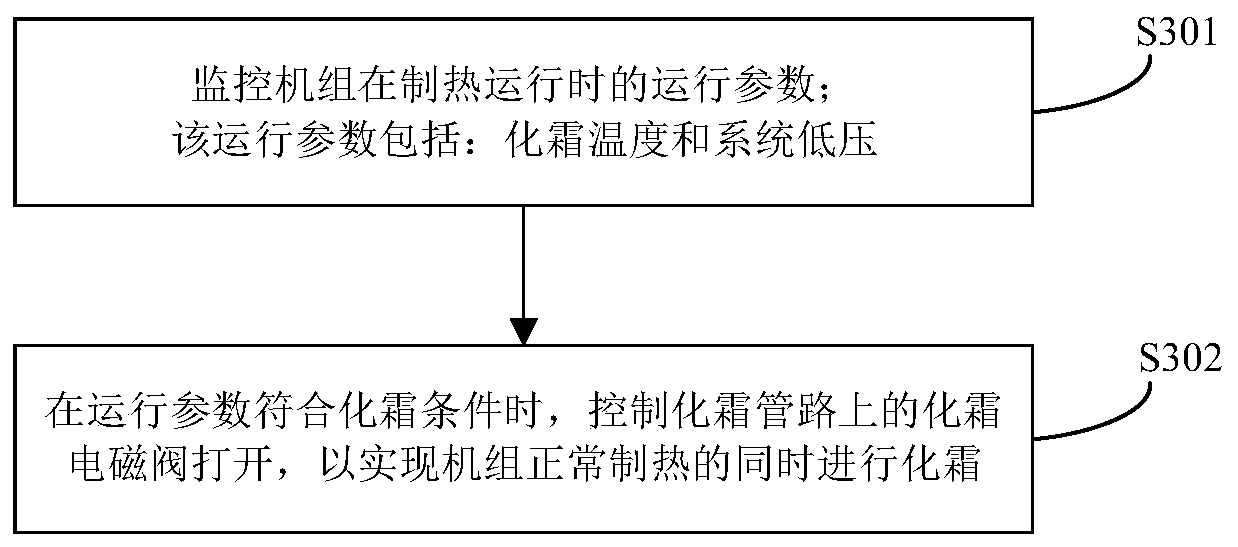

Air conditioner defrosting method and air conditioner defrosting system for realizing continuous heating

ActiveCN111306853ARealize continuous heatingExtend heating timeMechanical apparatusCorrosion preventionThermodynamicsFour-way valve

The invention discloses an air conditioner defrosting method and air conditioner defrosting system for realizing continuous heating. The air conditioner defrosting system comprises a defrosting pipeline and a defrosting electromagnetic valve; the inlet end of the defrosting pipeline is located on a connecting pipeline of a four-way valve and an indoor unit, and the outlet end of the defrosting pipeline is located on a liquid inlet main pipe of an outdoor unit; and the defrosting electromagnetic valve is arranged on the defrosting pipeline and is used for being opened when the air conditioner defrosting system executes defrosting operation, so that defrosting is performed while normal heating of a unit is achieved. According to the air conditioner defrosting system, the defrosting pipelineis additionally arranged in a conventional system and used for executing defrosting operation when the unit needs to be defrosted, and meanwhile continuous heating of the unit is achieved, so that thedefrosting period is shortened, the unit heating time is prolonged, and the unit energy efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Fluid compensation type air conditioning system, control method, computer equipment and terminal

ActiveCN112682905AImprove heating effectSolve easy frostingMechanical apparatusSpace heating and ventilation safety systemsThermal comfortEngineering

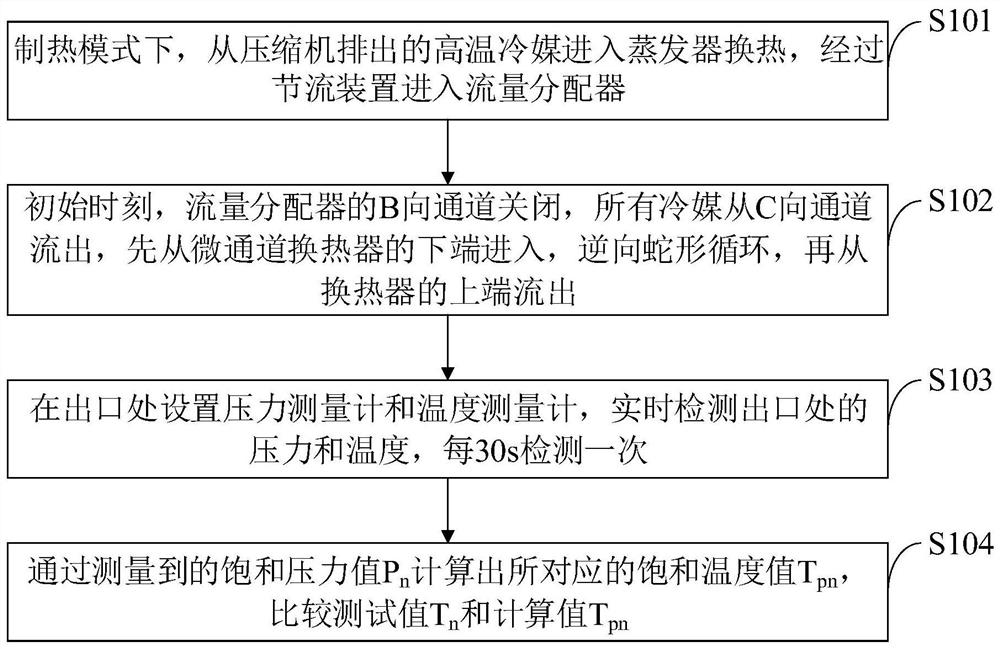

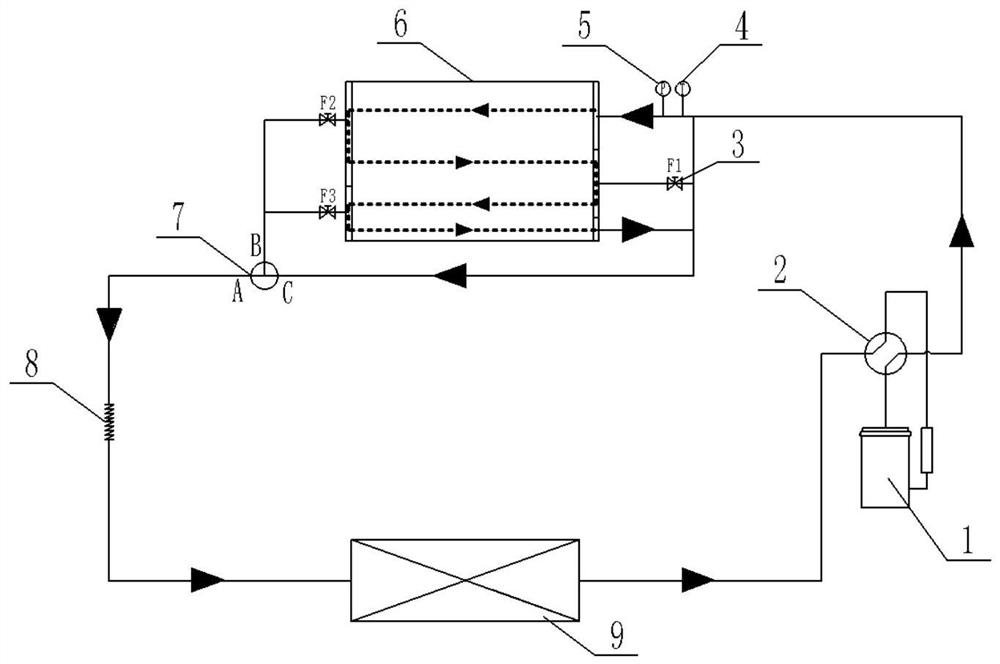

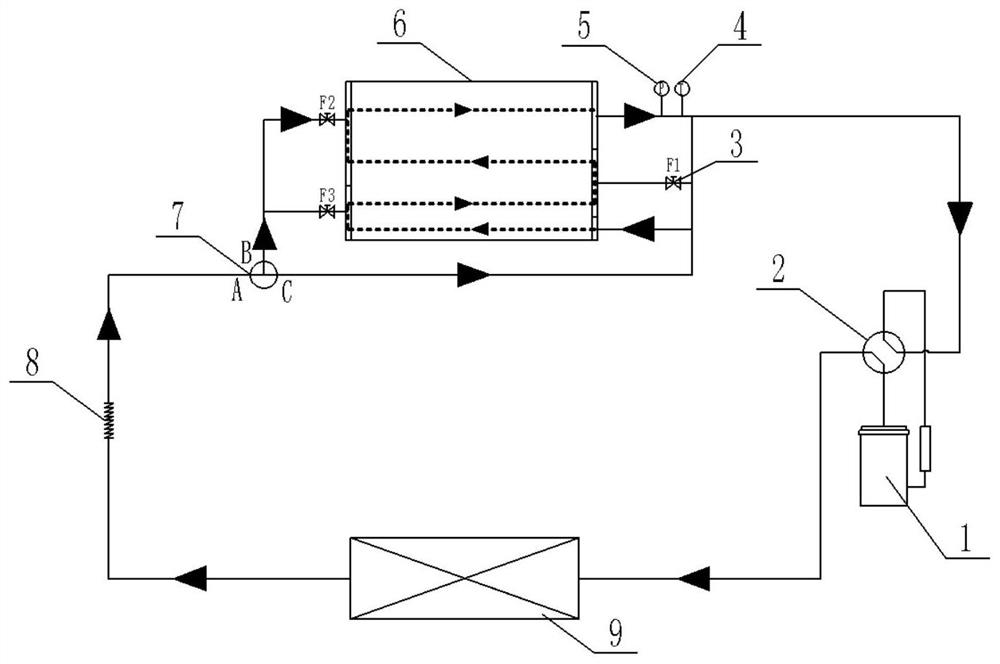

The invention belongs to the technical field of air conditioners, and discloses a fluid compensation type air conditioning system, a control method, computer equipment and a terminal. Under a heating mode, a high-temperature refrigerant discharged from a compressor enters an evaporator to exchange heat, and flows into a flow distributor through a throttling device; at an initial moment, a B-direction channel of the flow distributor is closed, so that all refrigerant flows out from a C-direction channel, enters from the lower end of a micro-channel heat exchanger to reversely circulate in an S-shaped mode, and flows out from the upper end of the heat exchanger; a pressure measuring meter and a temperature measuring meter are arranged at the outlet to detect pressure and temperature at the outlet every 30s; and a saturated temperature value Tpn is calculated according to a measured saturated pressure value Pn, and a test value Tn is compared with the calculated value Tpn. Heating performance under the heating mode of the micro-channel heat exchanger can be improved, so that the problem that a micro-channel is liable to frost is solved, continuous heating is realized, heating comfort is improved, and a frosting condition of the air conditioner is effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

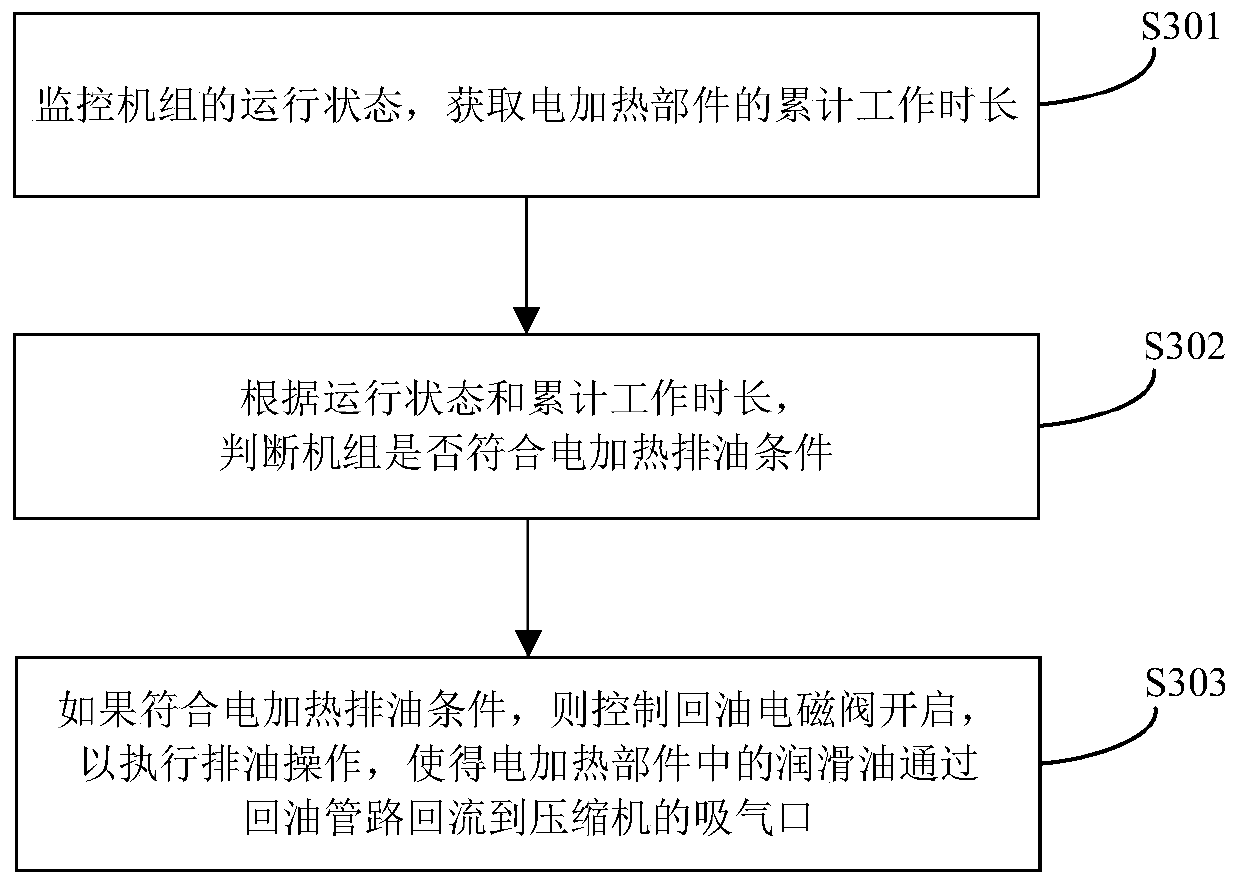

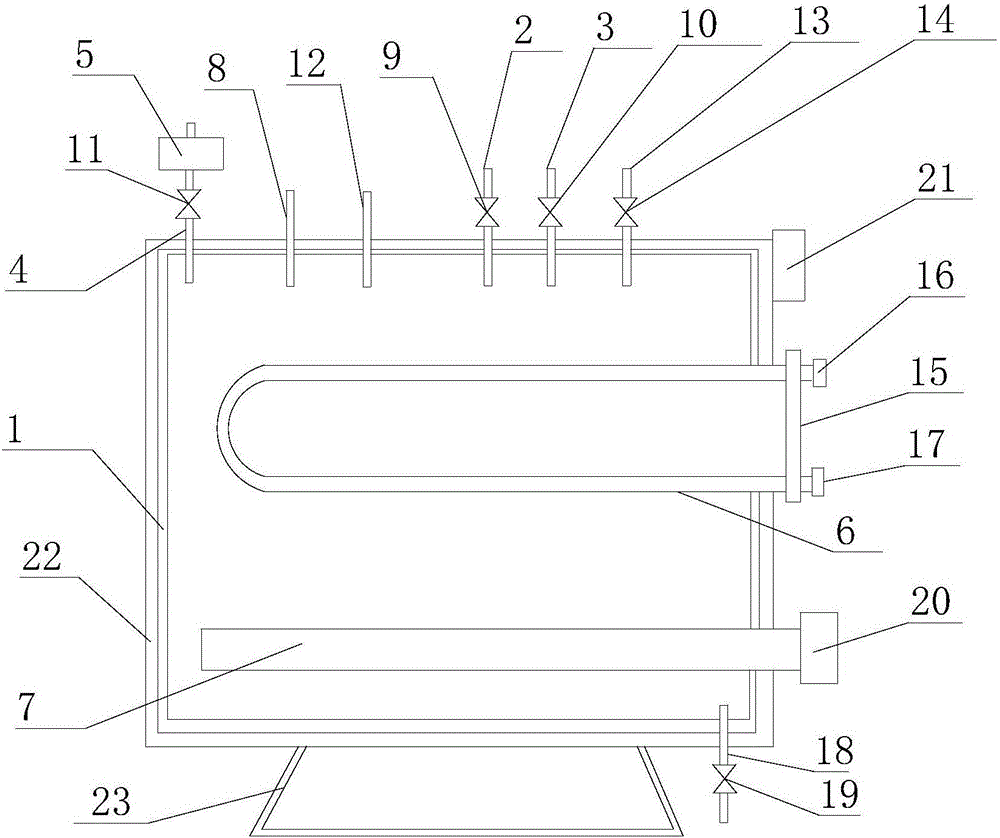

Low-temperature continuous heating oil return system, oil return control method and air conditioning equipment

PendingCN111102772ASolve the problem of oil storageGuaranteed operational reliabilityCompressorMechanical apparatusHeating oilCapillary Tubing

The invention discloses a low-temperature continuous heating oil return system, an oil return control method and air conditioning equipment. The system comprises an oil return pipeline, an oil returncapillary and an oil return electromagnetic valve, wherein the oil return pipeline is arranged between an air suction port of a compressor and an electric heating component; the oil return capillary and the oil return electromagnetic valve are arranged on the oil return pipeline, one end of the oil return capillary is connected with the bottom of the electric heating component, and the other end of the oil return capillary is connected with one end of the oil return electromagnetic valve; and the other end of the oil return electromagnetic valve is connected with the air suction port of the compressor. According to the low-temperature continuous heating oil return system, the oil return control method and the air conditioning equipment, the oil return pipeline is arranged between the air suction port of the compressor of the air conditioning equipment and the electric heating component, and the oil return capillary and the oil return electromagnetic valve are also arranged, so that lubricating oil in the electric heating component flows back to the air suction port of the compressor through the oil return pipeline. Therefore, the problem of oil storage in the electric heating component is solved, the operation reliability of a unit is ensured, the low-temperature heating capacity of the unit is improved, continuous heating in a low-temperature environment is realized, the indoor environment temperature is more stable, and the use comfort of users is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Phase change vacuum electric heating furnace

InactiveCN106440788AReliable structureEasy to operateCrucible furnacesExpansion tankElectric heating

The invention discloses a phase change vacuum electric heating furnace which comprises a furnace body, a liquid injection tube, a first exhaust tube, a second exhaust tube, a liquid guide tube, an expansion water tank, a heating coil, an electric heater, a pressure sensor, a first liquid level sensor, a second liquid level sensor and a controller; the expansion water tank has the action of overflowing excess water and also supplies micro-positive pressure for the interior of the furnace body to ensure the quantity of non-condensable gas to be zero; a liquid level control valve controls a liquid level in the furnace body; a gas release valve exhausts the non-condensable gas; a liquid injection valve injects water into the furnace body; the electric heater heats liquid at the lower part in the heating furnace body to enable the liquid to evaporate; evaporated liquid condenses into liquid to fall back into the liquid at the lower part in the heating furnace body again after heating the heating coil at the upper part in the furnace body; and the controller is connected with the electric heater, the pressure sensor, the first liquid level sensor, the second liquid level sensor, the liquid injection valve, the gas release valve and the liquid level control valve and controls the electric heater, the pressure sensor, the first liquid level sensor, the second liquid level sensor, the liquid injection valve, the gas release valve and the liquid level control valve to act. The phase change vacuum electric heating furnace is simple and reliable in structure, liable to operate, convenient to maintain, long in service life, high in efficiency and wide in application range.

Owner:ANBANG ELECTRICAL GRP

Straw bundling semi-gasification combustion boiler

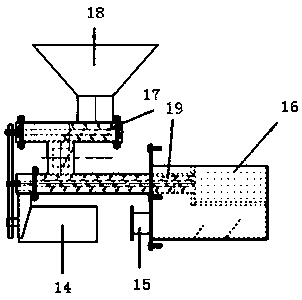

ActiveCN106196176ATake advantage ofRealize bundling and semi-gasification combustion heatingChemical industryStove/ranges for heating waterCombustion chamberCombustor

The invention discloses a straw bundling semi-gasification combustion boiler mainly comprising semi-gasification combustion chambers, a gas mixing device and a heat source combustor; the semi-gasification combustion chambers are double combustion chambers, and vent holes are respectively formed in the bottom and middle of the semi-gasification combustion chambers; the gas mixing device is of a sleeve-shaped structure and is provided with a smoke channel at the outer ring and an air channel at the inner ring; the heat source combustor comprises a feeding device and a porous slot-type fire grate, and a cavity at the upper part of the porous slot-type fire grate is a fire bed; an inlet is formed at the rear end of the gas mixing device, the smoke channel at the outer ring communicates with a smoke vent of the semi-gasification combustion chambers, and the air channel at the inner ring is connected with a draught fan; and the front end of the gas mixing device is a smoke and air mixing end corresponding to the position of the fire bed located on the heat source combustor. The structure is an innovation in the field of direct straw bundling gasification combustion, is clean, environmental-friendly, sufficient in combustion, high in heat utilization efficiency, capable of realizing standardized discharge and low in cost and is a breakthrough in the field of boiler heating for village and township enterprises and public institutions.

Owner:LIAONING HEBAIYI BIOMASS TECH DEV

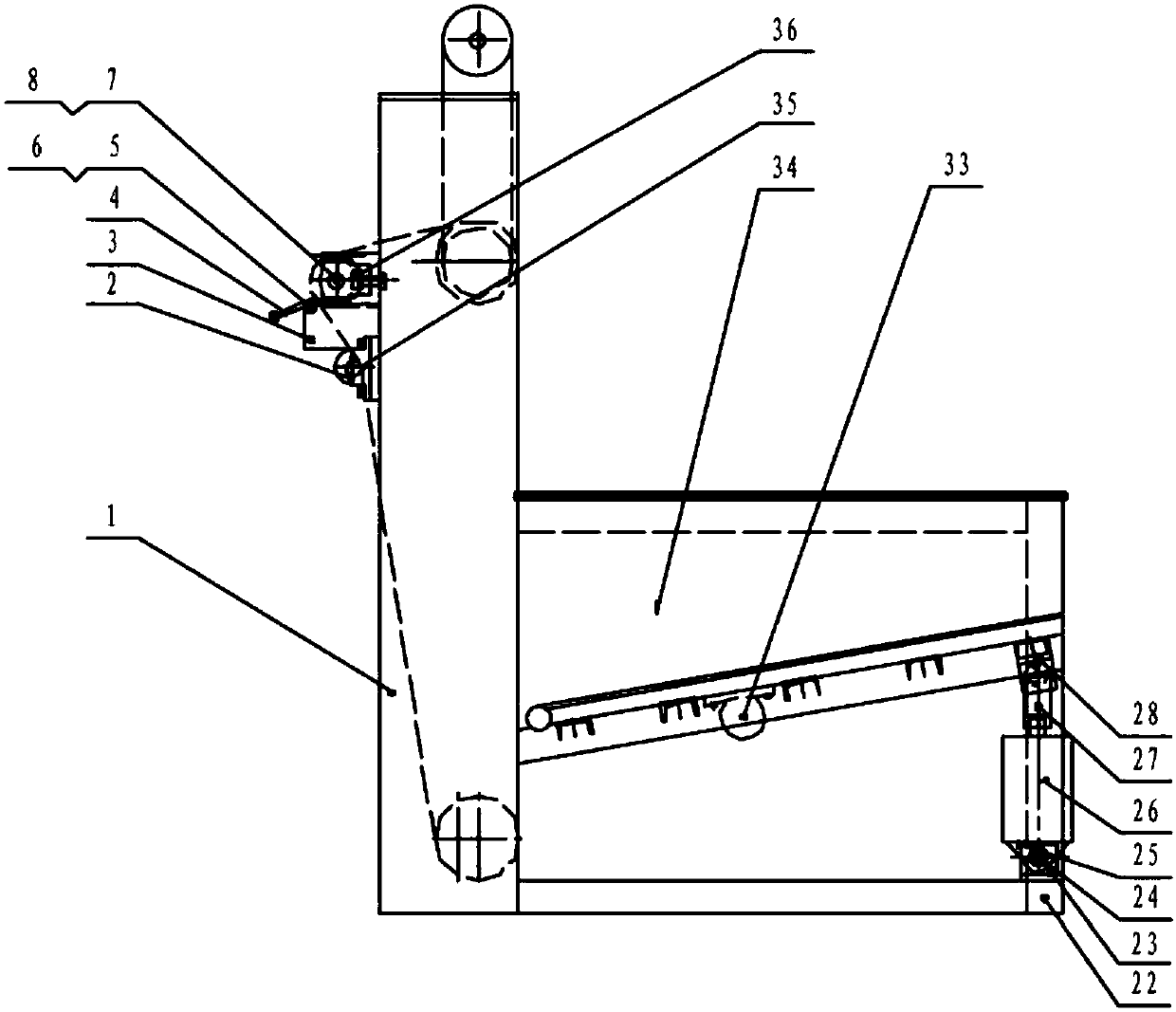

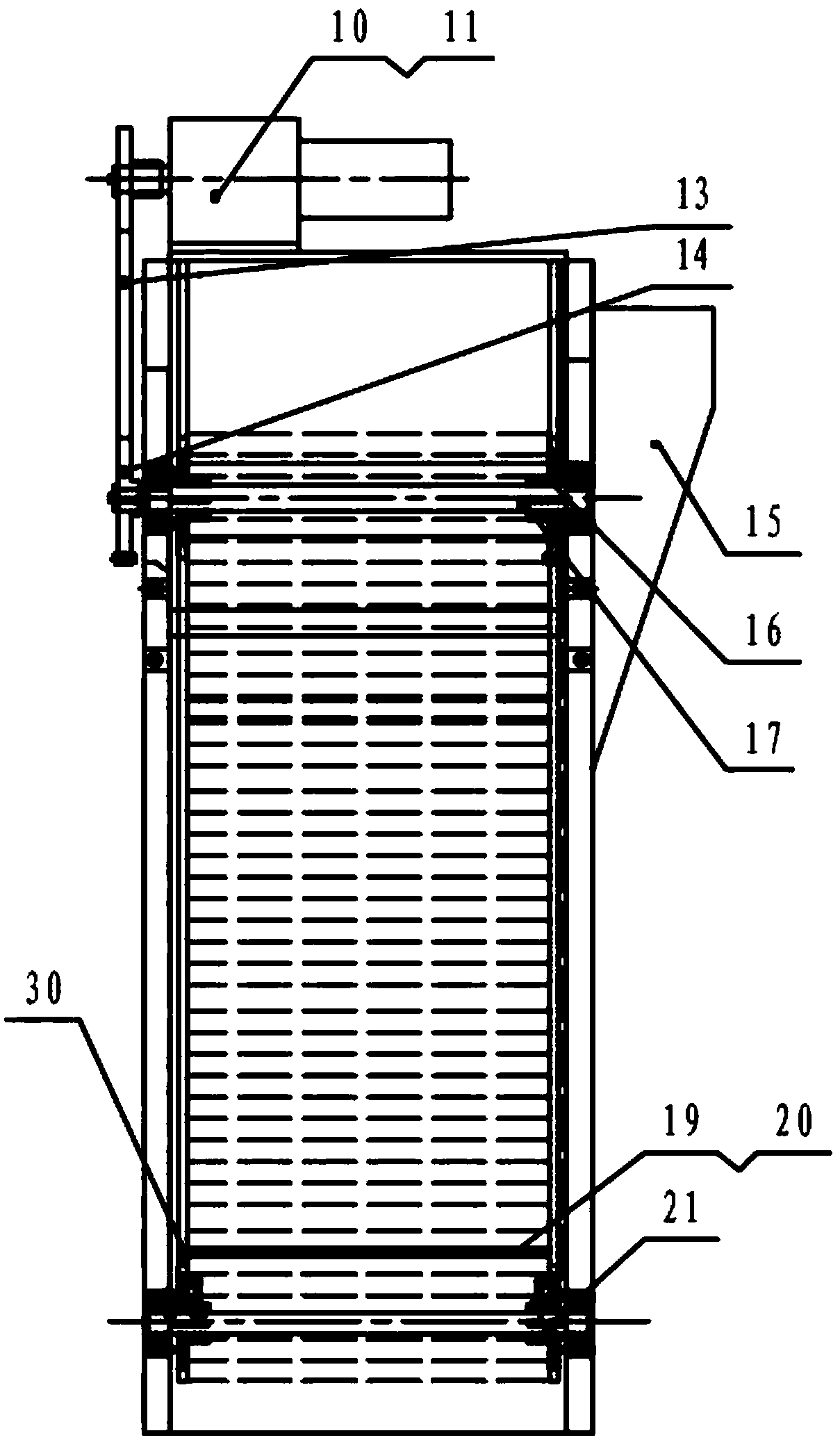

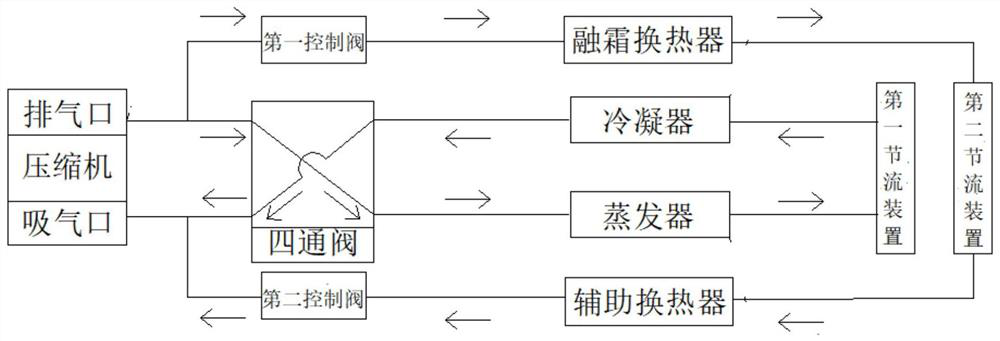

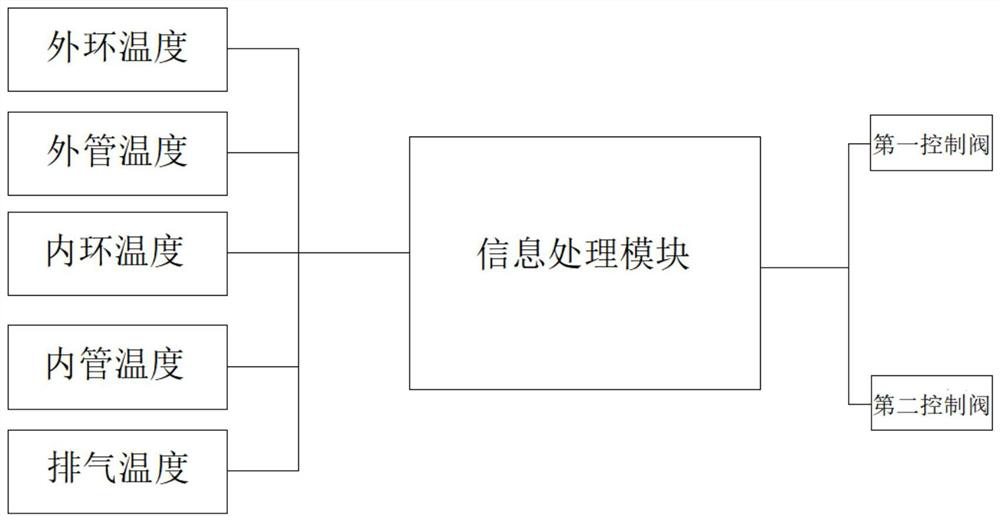

Air-conditioning system and control method thereof

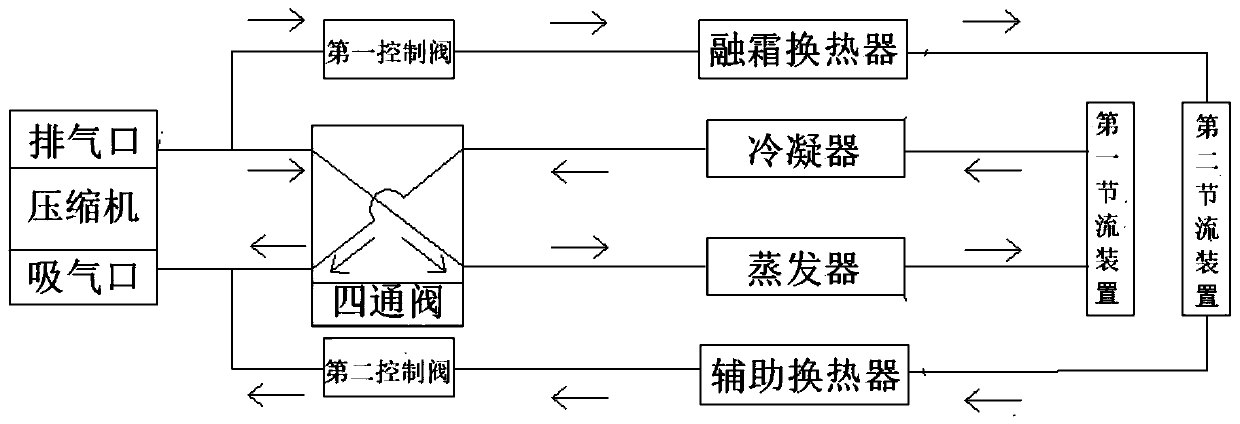

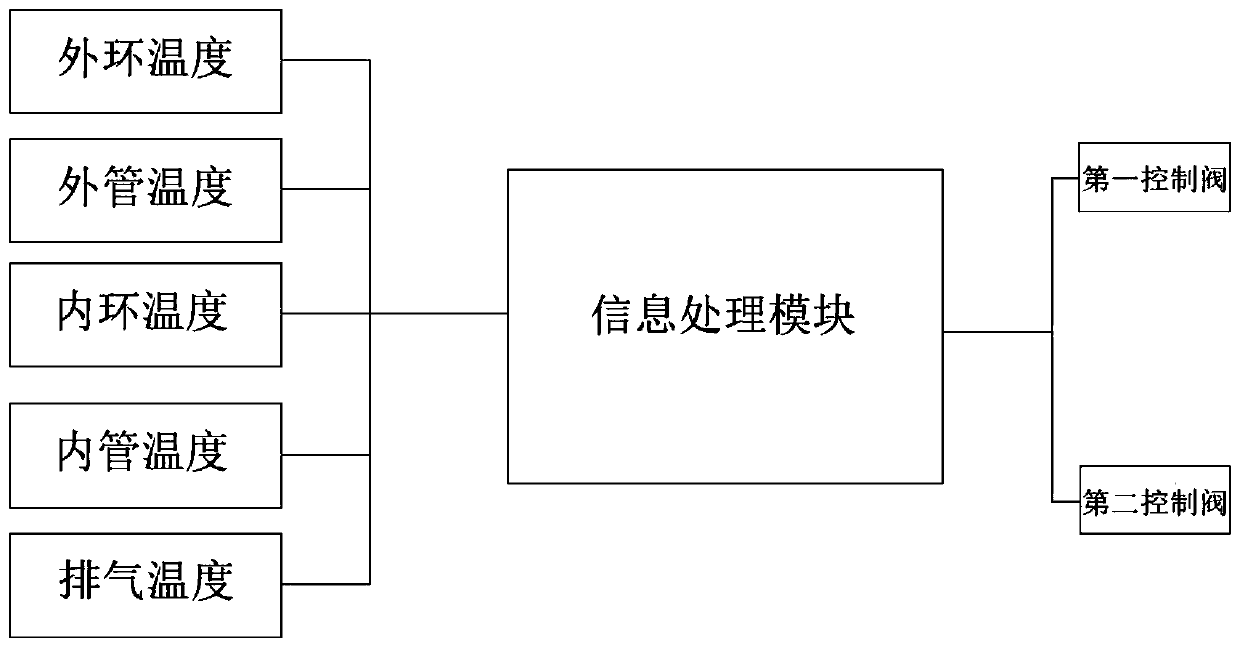

ActiveCN110553417AReduce the probability of frostRealize continuous heatingMechanical apparatusSpace heating and ventilation safety systemsFluid controlFour-way valve

The invention discloses an air-conditioning system and a control method thereof. The air-conditioning system comprises a compressor, a four-way valve, an evaporator, a condenser and a first throttlingdevice. The compressor, the condenser, the first throttling device and the evaporator form a first loop through the four-way valve; the compressor, a defrosting heat exchanger, a second throttling device and an auxiliary heat exchanger form a second loop through a fluid control valve; and the defrosting heat exchanger can transmit own heat to the condenser in a heat conduction mode, and defrosting of the condenser is achieved. A relatively independent defrosting system is adopted, an existing machine only needs to be changed slightly, the frosting probability of the condenser can be lowered,defrosting can be achieved even though frosting occurs, and thus an indoor unit can perform continuous heating and does not stop.

Owner:GREE ELECTRIC APPLIANCES INC

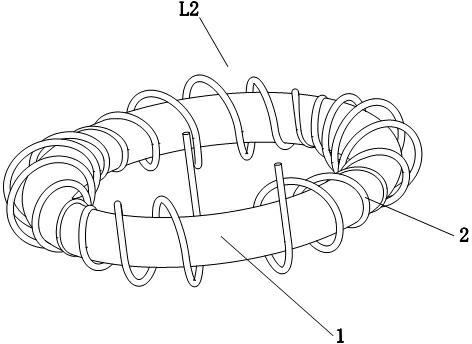

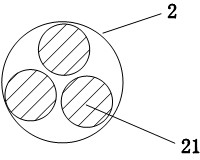

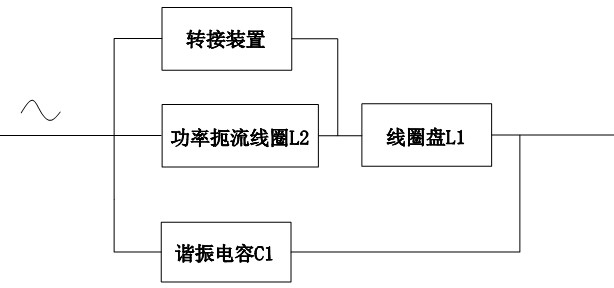

Power choking coil and electromagnetic induction heater adopting same

ActiveCN102427625AImprove the heating effectAchieve zero voltage turn-onInduction heatingCapacitanceHemt circuits

The invention relates to a power choking coil, which comprises an annular magnetizer and a coil winding encircled on the annular magnetizer, wherein the outer surface of the annular magnetizer (1) is coated with an insulating layer. The power choking coil is characterized in that the coil winding is formed by twisting more than three strands of enamelled wires. An electromagnetic induction heater provided by the invention comprises a coil panel and a resonance capacitance in parallel, and is characterized in that the power choking coil is serially connected between the coil panel and the resonance capacitance, and switching devices are respectively connected onto the two ends of the power choking coil. Compared with the prior art, the invention has the following beneficial effects that: since the electromagnetic induction heater is additionally provided with the power choking coil on the front end of the coil panel, when low-power heating is required, the power chocking coil is connected into the circuit through the switching devices, the existing resonance state is changed, zero-voltage switch of an IGBT (Insulated Gate Bipolar Transistor) is realized, the heat loss of the IGBT is small, and the system is safe, therefore, not only is the low-power continuous heating realized, but also the heating effect of the electromagnetic induction heater is better.

Owner:MIDEA GRP CO LTD

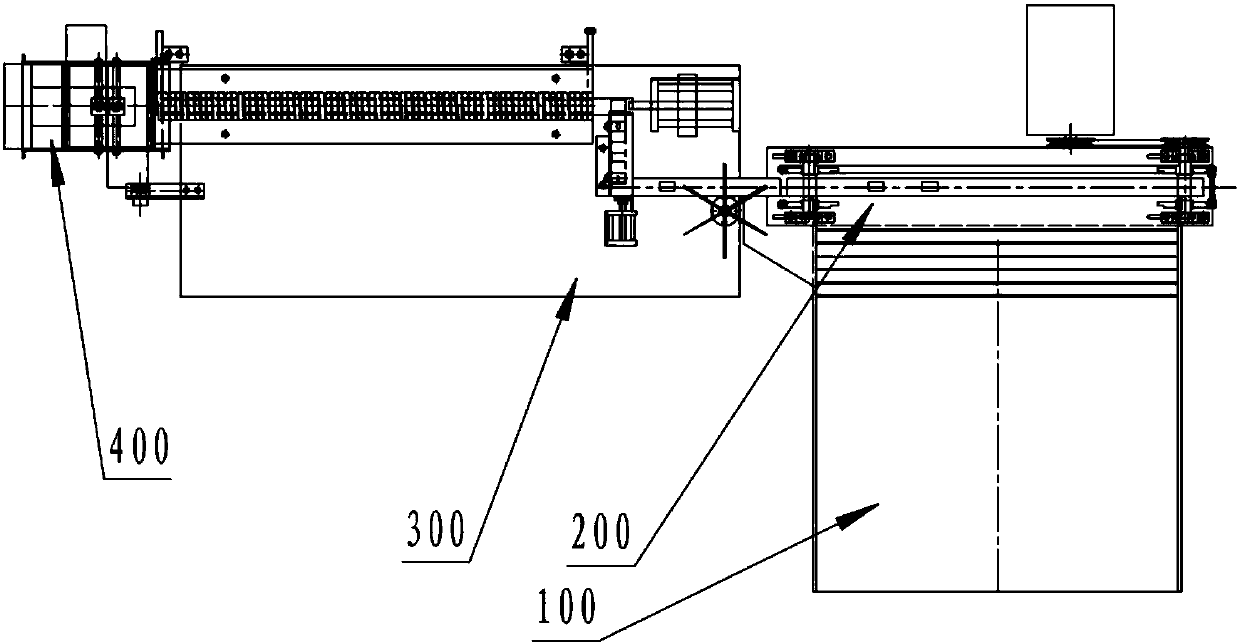

A fully automatic device for heating nut blanks

ActiveCN106000911BGuaranteed continuityStable temperatureOhmic-resistance heatingSortingComing outUltimate tensile strength

The invention discloses a full-automatic device for nut blank heating. The full-automatic device comprises a vertical lifting system, a material conveying system, a material rotating heating system and a heated blank transmission separation system that are arranged sequentially; after being lifted by the vertical lifting system, blanks are sent into a bearing guide rail of the material conveying system, then are conveyed to a material receiving plate of the material rotating heating system by a feeding plate of the material conveying system; the irregular blanks return to a stock bin through a material receiving disc of the vertical lifting system, and the regular blanks are sent to a material rotating plate of the material rotating heating system, and are pushed into a heating coil to be heated uniformly; the blanks coming out after heating are subjected to temperature detection separation; and the blanks having qualified temperatures enter a forming process. Compared with the prior art, the full-automatic device has the positive effects that with the adoption of the full-automatic device, the product heating continuity is guaranteed, the product temperature stability is ensured, the product quality is improved, the labor intensity is reduced, and the working efficiency is improved to a great extent.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

A defrosting method for an air-conditioning system and the air-conditioning system

ActiveCN110553417BReduce the probability of frostRealize continuous heatingMechanical apparatusSpace heating and ventilation safety systemsFour-way valveFluid control

An air-conditioning system and its control method, the air-conditioning system includes a compressor, a four-way valve, an evaporator, a condenser, a first throttling device, the compressor passes through the four-way valve and the condenser, the first throttling device, and the evaporator The compressor forms the first circuit; the compressor forms the second circuit through the fluid control valve, the defrosting heat exchanger, the second throttling device, and the auxiliary heat exchanger; the defrosting heat exchanger can transfer its own heat through heat conduction Give the condenser to defrost the condenser. The present invention adopts a relatively independent defrosting system, which can reduce the frosting probability of the condenser only by slightly modifying the existing models, and can realize continuous heating of the indoor unit during defrosting without shutting down even if frosting occurs.

Owner:GREE ELECTRIC APPLIANCES INC

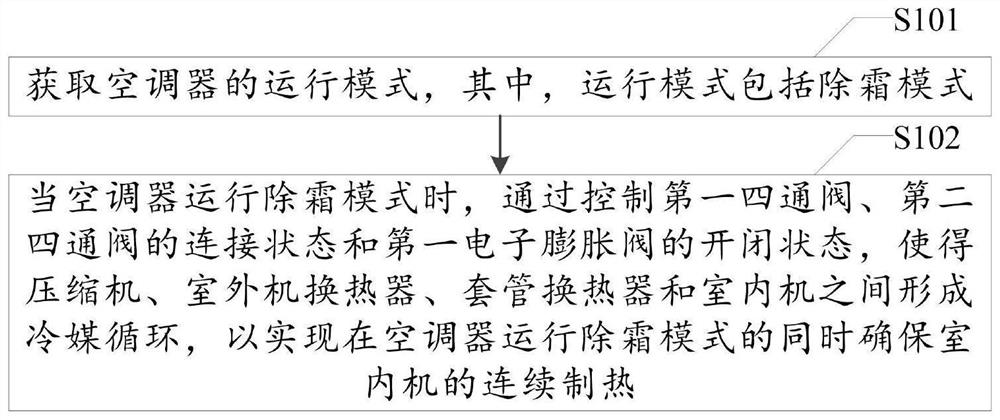

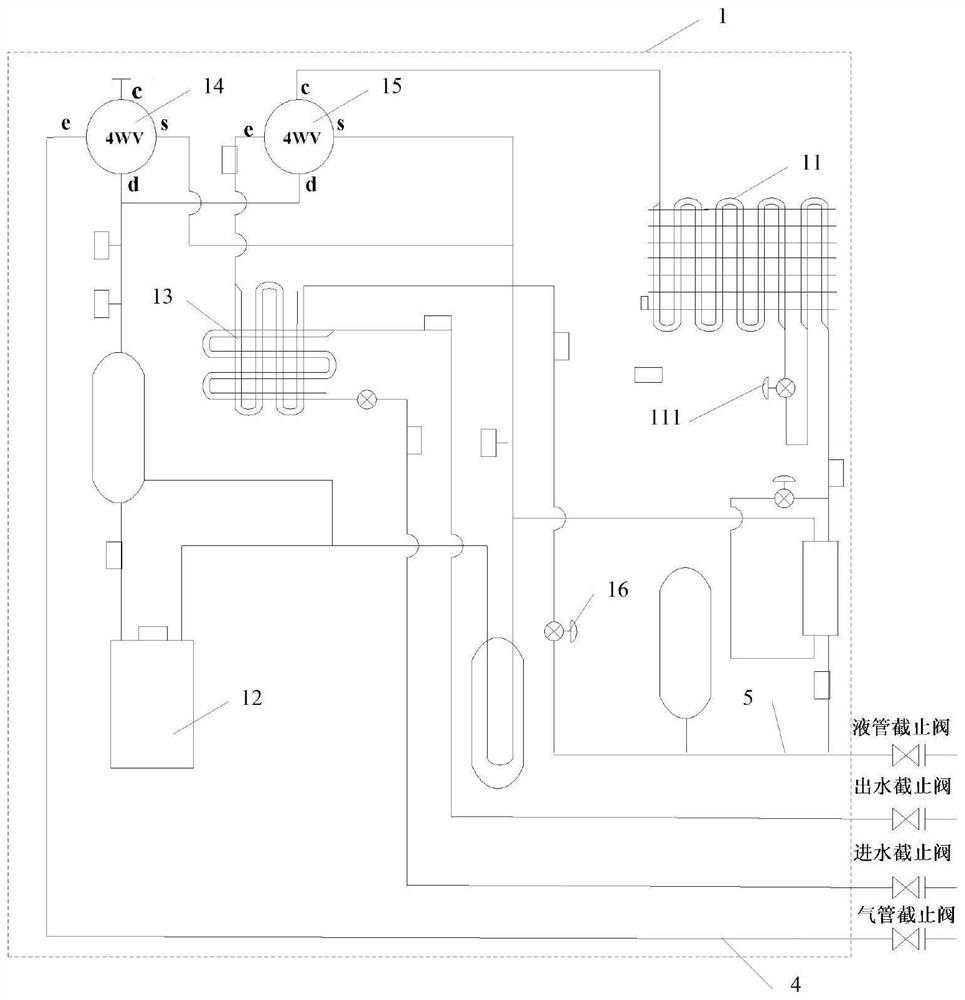

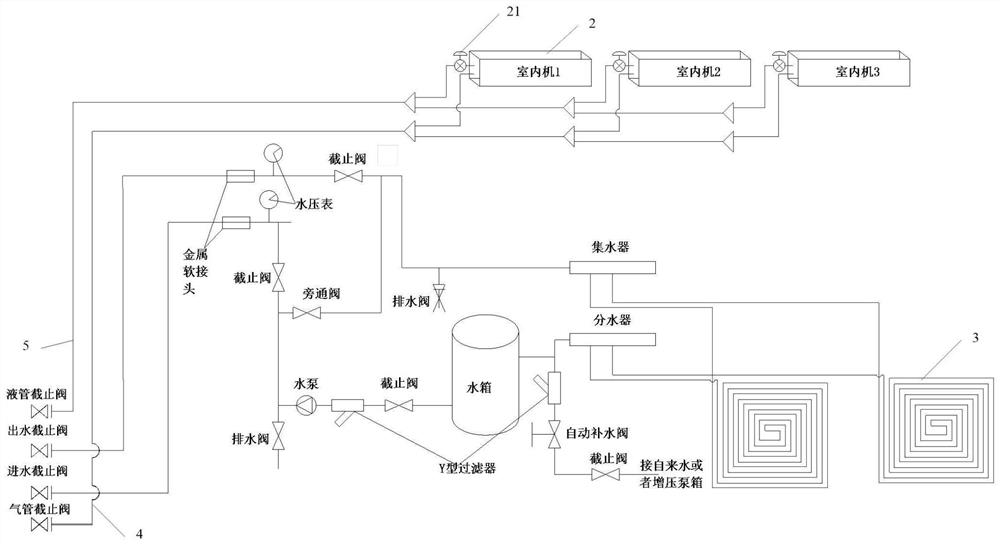

Air conditioner control method, system and device, medium and air conditioner

PendingCN114719400AEnsure continuous heatingRealize continuous heatingMechanical apparatusCorrosion preventionEngineeringMechanical engineering

The invention relates to the technical field of air conditioner control, particularly provides an air conditioner control method, system and device, a medium and an air conditioner, and aims to solve the problem that an indoor unit cannot ensure continuous heating when the air conditioner runs in a defrosting mode. In order to achieve the purpose, when the air conditioner operates in the defrosting mode, refrigerant circulation can be formed among a compressor, an outdoor unit heat exchanger, a double-pipe heat exchanger and an indoor unit by controlling the connection state of a first four-way valve and a second four-way valve and the opening and closing state of a first electronic expansion valve, and it is ensured that when the air conditioner operates in the defrosting mode, refrigerant circulation can be formed among the compressor, the outdoor unit heat exchanger, the double-pipe heat exchanger and the indoor unit. And continuous heating of the indoor unit can be ensured, and the user experience is effectively improved.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

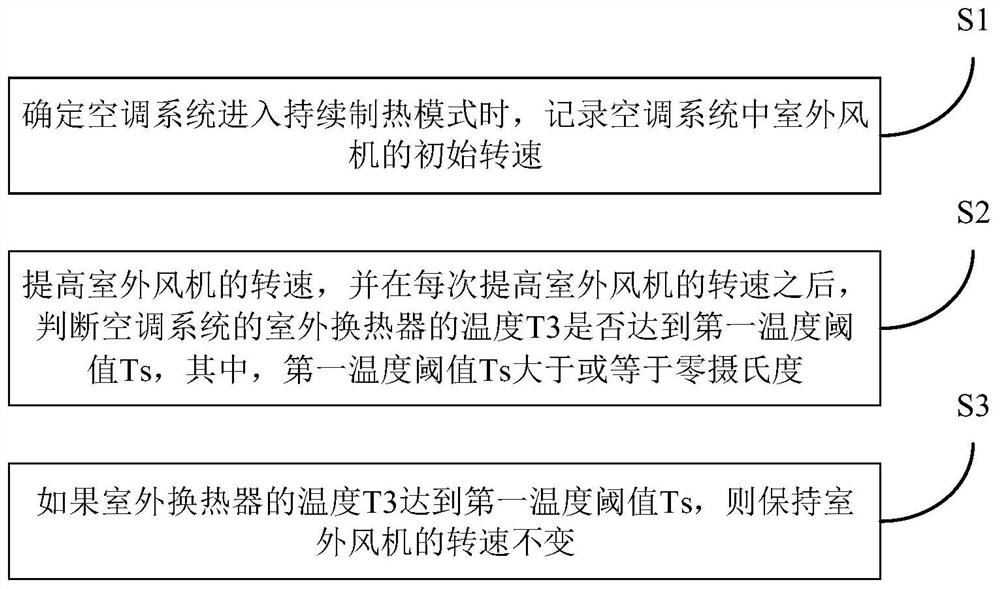

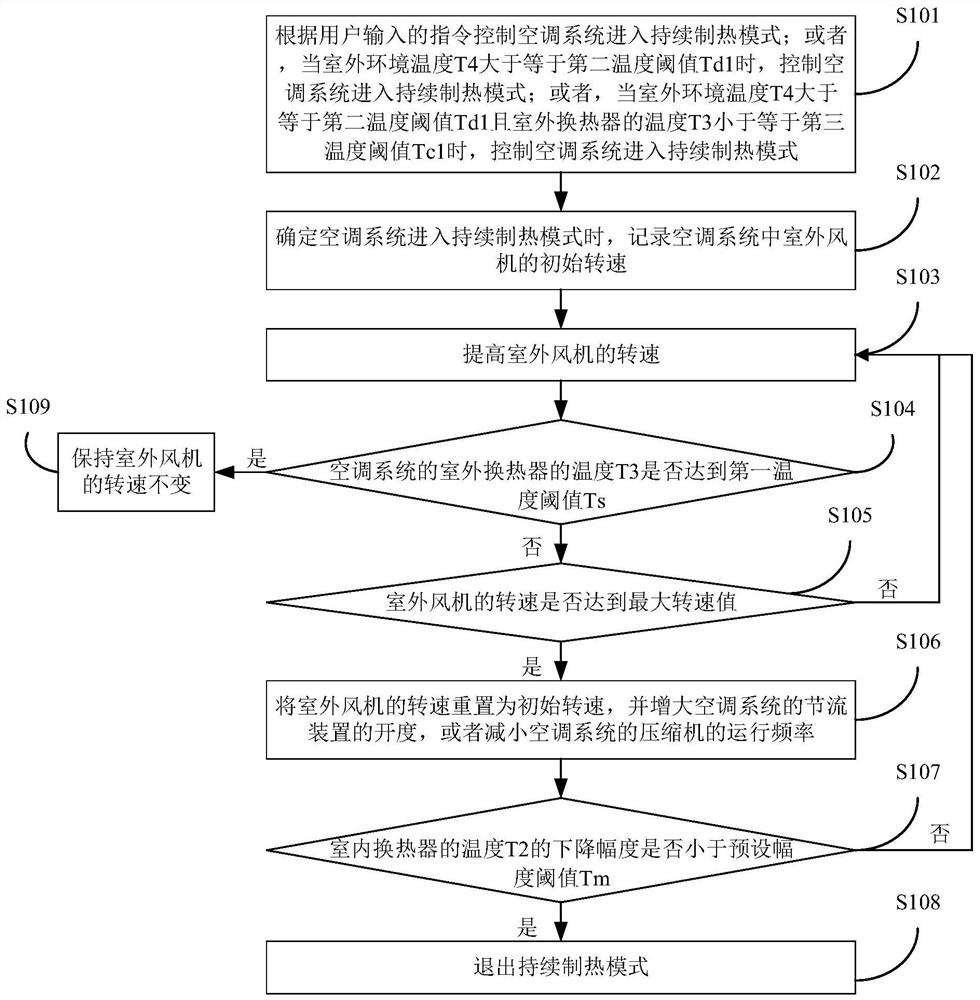

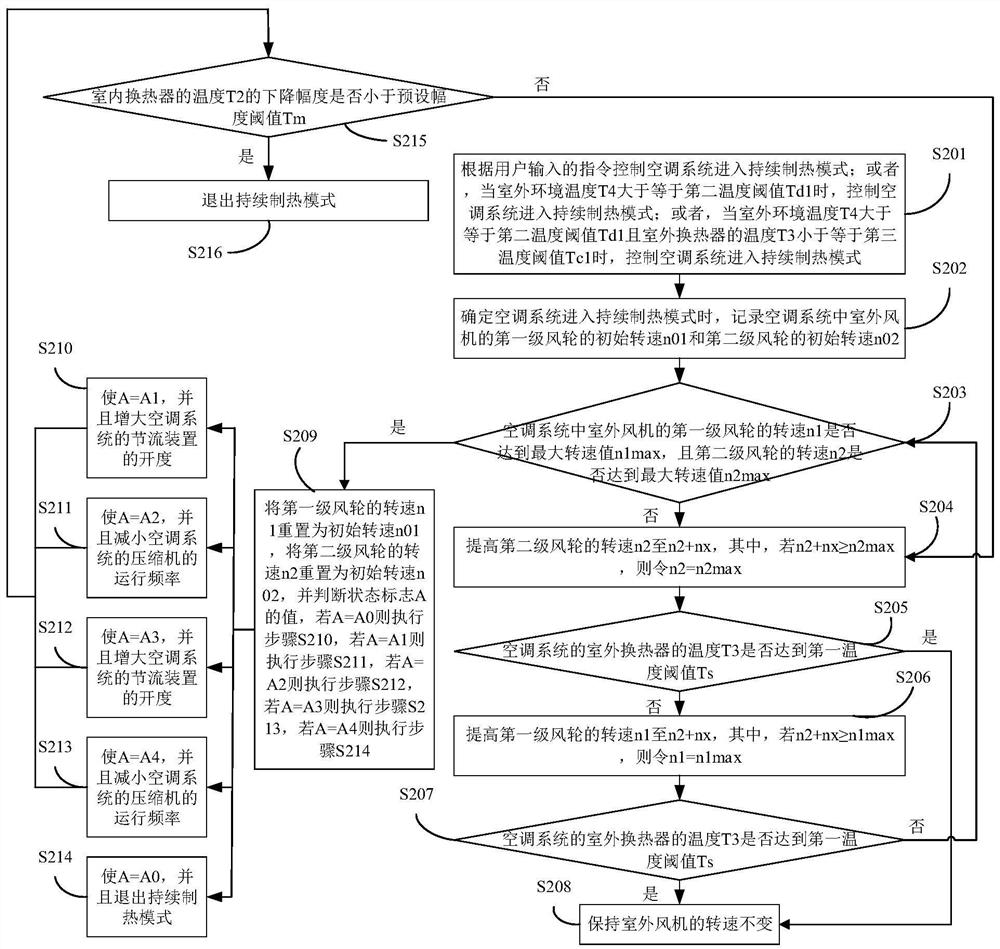

Air-conditioning system and continuous heating control method thereof

ActiveCN110454912BIncrease speedGuaranteed heating effectMechanical apparatusSpace heating and ventilation safety systemsThermal comfortEngineering

The invention provides an air conditioning system and a continuous heating control method thereof. The method comprises the steps that when it is determined that the air conditioning system enters a continuous heating mode, the initial rotating speed of an outdoor fan in the air conditioning system is recorded; the rotating speed of the outdoor fan is increased, and after the rotating speed of theoutdoor fan is increased every time, and whether the temperature of an outdoor heat exchanger of the air conditioning system reaches a first temperature threshold value is judged, wherein the first temperature threshold value is larger than or equal to zero DEG C. If the temperature of the outdoor heat exchanger reaches a first temperature threshold value, the rotating speed of the outdoor fan iskept unchanged, so that the possibility of frosting of the outdoor heat exchanger can be reduced under the condition of ensuring the heating capacity, continuous heating is achieved, the indoor environment temperature is prevented from being excessively fluctuated due to defrosting, and the heat comfort of a user is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

High temperature continuous nitrogen heater

ActiveCN105627560BSolve the problem of thermal expansionSolve conductivity problemsAir heatersPower flowNitrogen

The invention provides a high-temperature continuous nitrogen heater. The high-temperature continuous nitrogen heater comprises a cylinder, a water cooling positive electrode, a water cooling negative electrode and a heating element; the heating element is mounted on the axis of the cylinder, and one end thereof is connected with the water cooling positive electrode through a slide transfer piece; the water cooling positive electrode is connected with a power supply by penetrating out of a water cooling end surface flange tightly connected to one end of the cylinder; the other end of the heating element penetrates out of a graphite baffle plate at the other end of the closed cylinder; upper and lower two water cooling negative electrodes mounted on the heating element through an electrode transfer disc are connected with the power supply after penetrating out of through holes in the wall of the cylinder; the heating element is a sandwich layer structure consisting of a graphite straight pipe on the outer layer and a graphite straight pipe with a spiral fin on the outer pipe wall on the inner layer; a spiral channel is formed between the outer-layer pipe and the inner-layer pipe through the spiral fin; and a through hole is formed in the slide transfer piece connected to one end of the heating element. The high-temperature continuous nitrogen heater solves the difficulties of thermal expansion of the heating element and high-current electric conduction, and can realize continuous heating of nitrogen currents.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com