Low-temperature continuous heating oil return system, oil return control method and air conditioning equipment

An oil return system and low-temperature technology, which is applied in lighting and heating equipment, mechanical equipment, refrigerators, etc., can solve the problem of refrigerated oil accumulated in electric heating components, achieve stable indoor environment temperature, increase low-temperature heating capacity, and ensure reliable operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

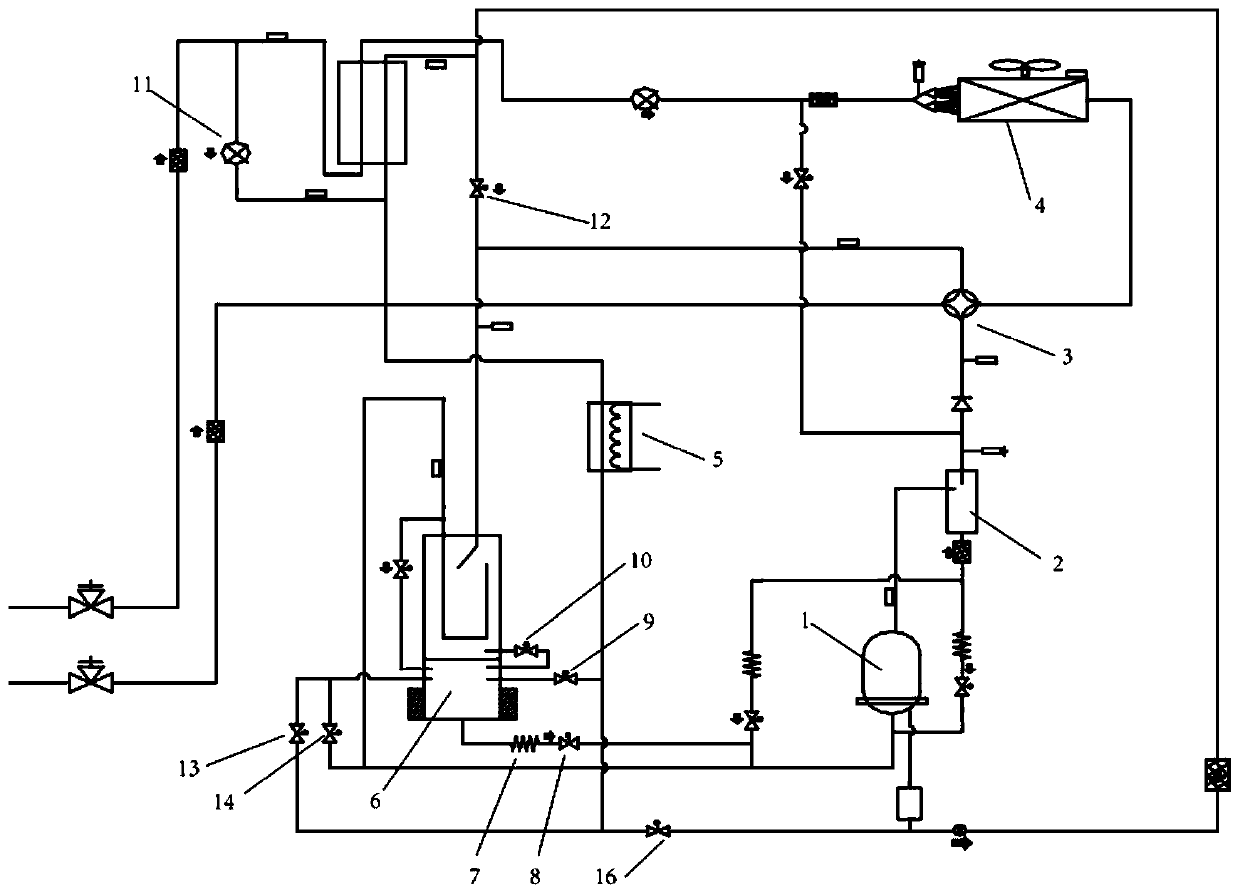

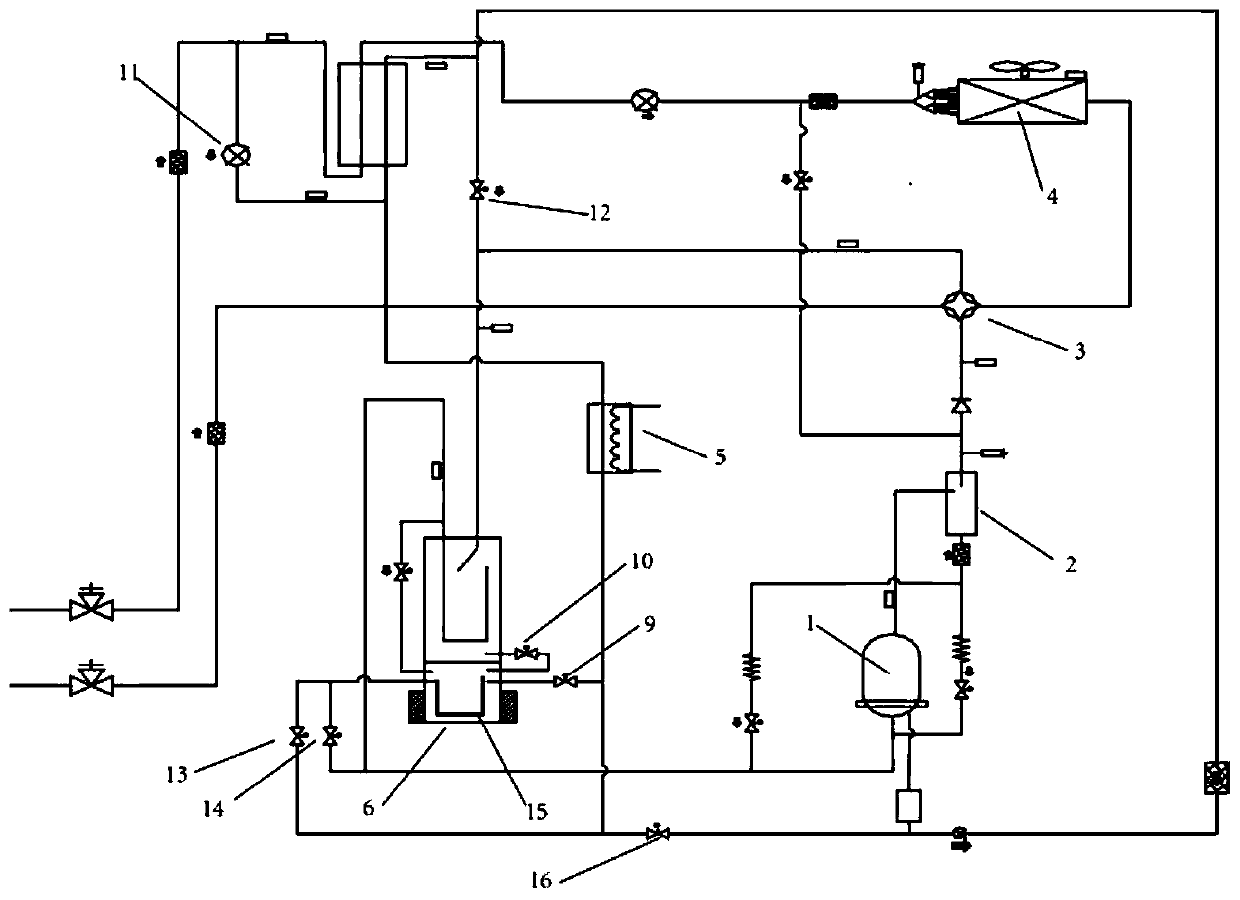

[0031] figure 1 It is a structural schematic diagram of a low-temperature continuous heating oil return system according to an embodiment of the present invention, such as figure 1 As shown, the system includes an indoor unit and an outdoor unit. The outdoor unit includes an outdoor heat exchanger 4, a compressor 1, an auxiliary throttling component 11, an electric heating component 6, etc. The above system also includes:

[0032] An oil return pipeline is arranged between the suction port of the compressor 1 and the electric heating component 6, so that the lubricating oil in the electric heating component 6 flows back to the suction port of the compressor 1 through the oil return pipeline;

[0033] The oil return capillary 7 and the oil return solenoid valve 8 are arranged on the oil return pipeline, one end of the oil return capillary 7 is connected to the bottom of the electric heating component 6, the other end is connected to one end of the oil return solenoid valve 8, a...

Embodiment 2

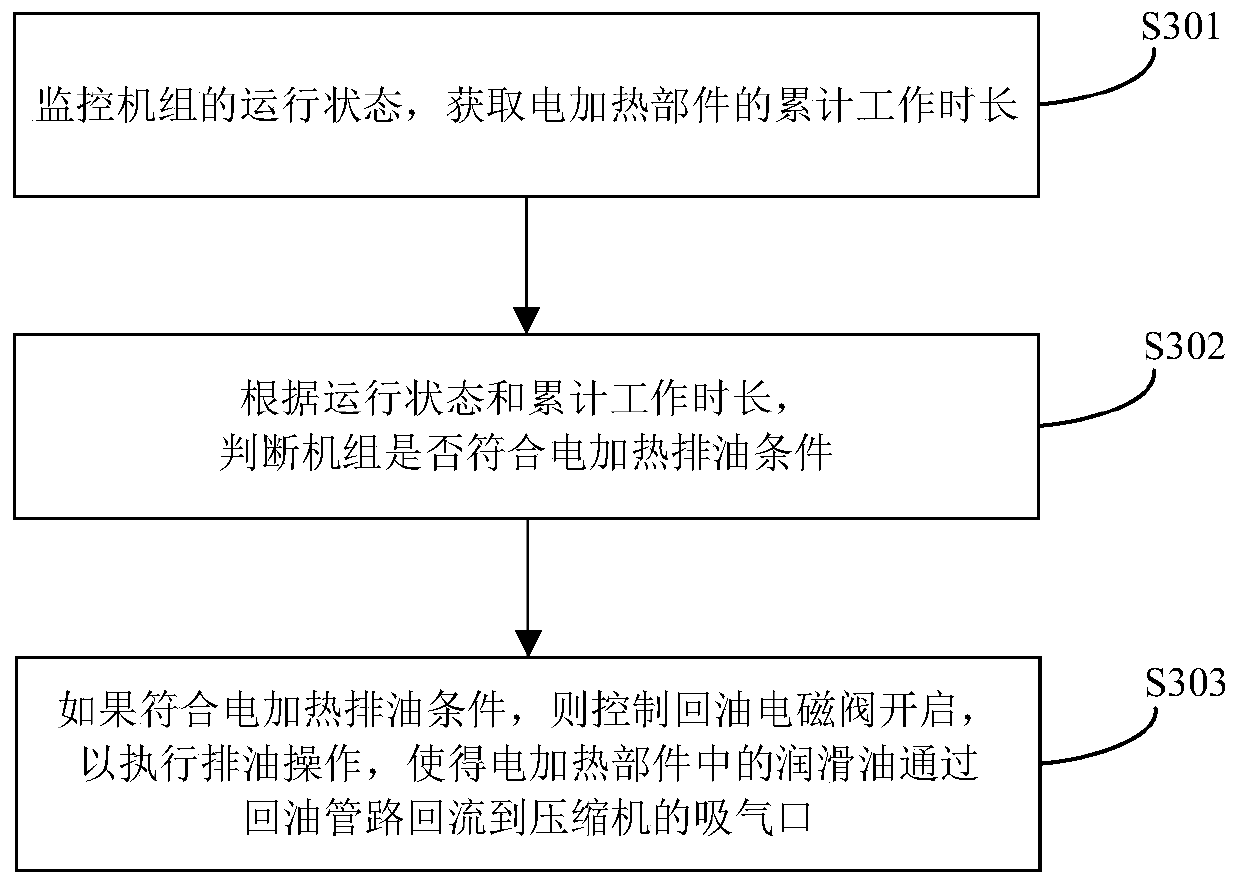

[0050] image 3 It is a flow chart of the oil return control method for low-temperature continuous heating according to an embodiment of the present invention. This method is applied to the oil return system for low-temperature continuous heating introduced in the above embodiments, such as image 3 As shown, the method includes the following steps:

[0051] Step S301, monitoring the running state of the unit, and obtaining the cumulative working hours of the electric heating components;

[0052] Step S302, judging whether the unit meets the electric heating oil discharge condition according to the running state and the accumulated working hours;

[0053] Step S303, if the oil discharge condition of the electric heating is met, the oil return solenoid valve is controlled to open to perform the oil discharge operation, so that the lubricating oil in the electric heating component flows back to the suction port of the compressor through the oil return pipeline.

[0054] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com