A fully automatic device for heating nut blanks

A fully automatic, blank technology, applied in induction heating devices, electric heating devices, induction heating and other directions, can solve the problems of not being able to effectively guarantee product quality, hidden safety hazards and labor-intensive, and inability to detect products online. The heating temperature of the material is too high or too low, the effect of eliminating safety hazards and facilitating online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

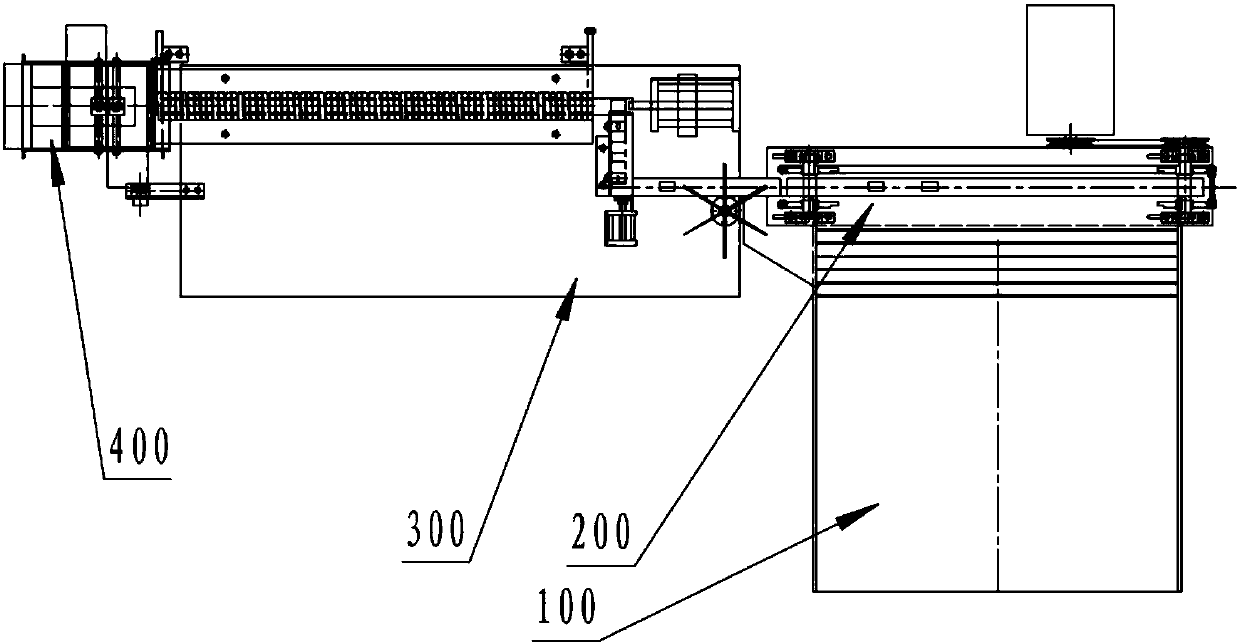

[0035] A fully automatic device for heating nut blanks, such as figure 1 As shown, it includes four major parts: vertical lifting system 100, material transfer system 200, material transfer heating system 300, and heating billet transmission and sorting system 400.

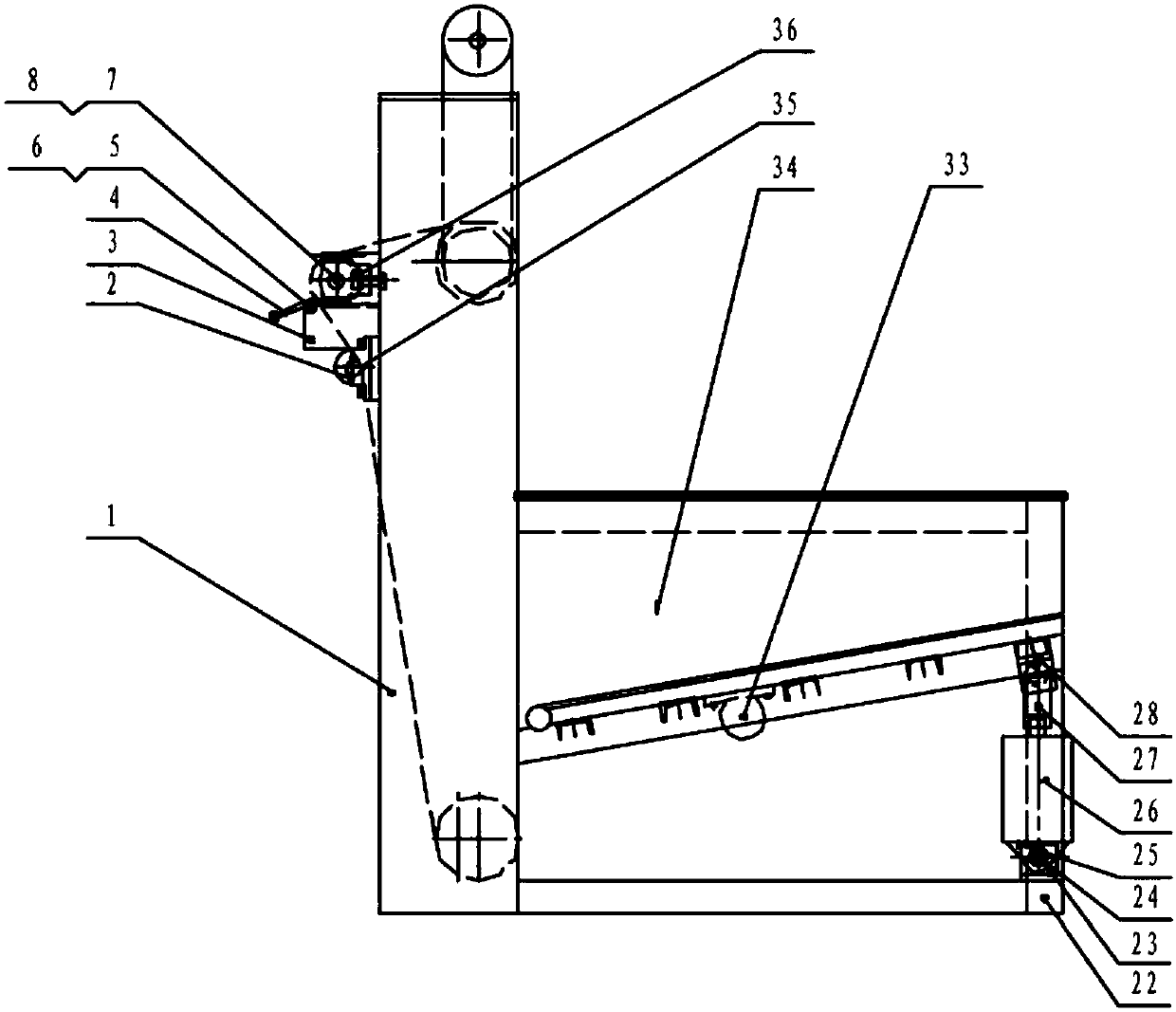

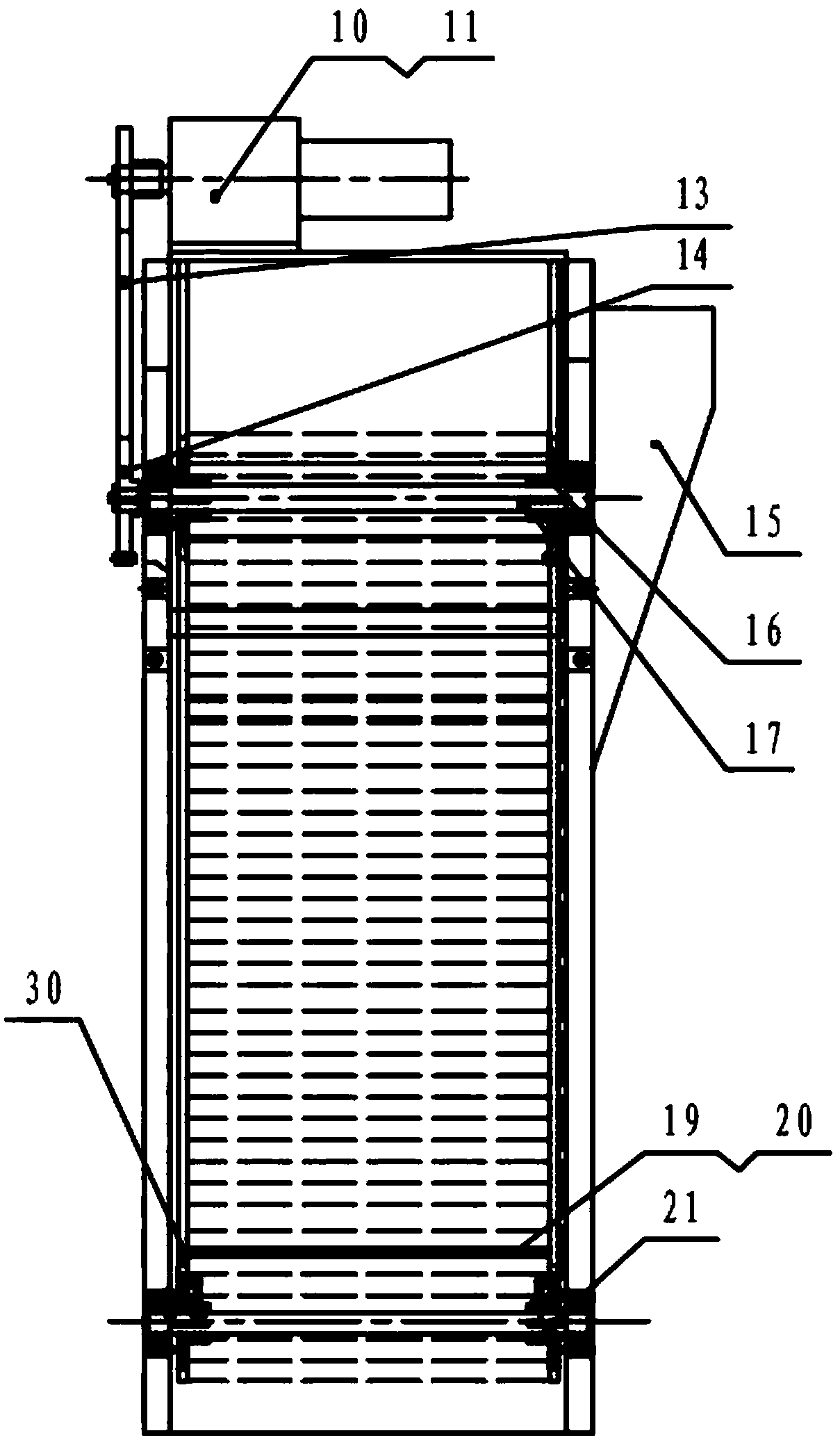

[0036] Such as figure 2 and image 3 As shown, the vertical lifting system 100 includes a machine bed 1, a bearing with seat 2, a fixed plate 3, a guide plate 4, a rotating sleeve 5, a pin 6, a shaft 7, a tensioning roller 8, a pendulum reducer 10, and a sprocket 11 , chain 13, sprocket 14, receiving tray 15, sprocket 16, main transmission shaft 17, connecting plate 19, permanent magnet 20, slave transmission shaft 21, base plate 22, base 23, shaft 24, bearing 25, cylinder 26. Connection 27, rubber plate 28, chain 30, vibration motor 33, feed bin 34, pin 35, fixed seat 36, etc.

[0037] Such as Figures 4 to 6 As shown, the material transmission system 200 transmission system includes: bracket 201, pendulum r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com