Power choking coil and electromagnetic induction heater adopting same

A technology of electromagnetic induction heating and choke coils, which is applied in the direction of induction heating, can solve the problems of IGBT heat loss and poor heating effect, and achieve the effects of small heat loss, good heating effect and system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

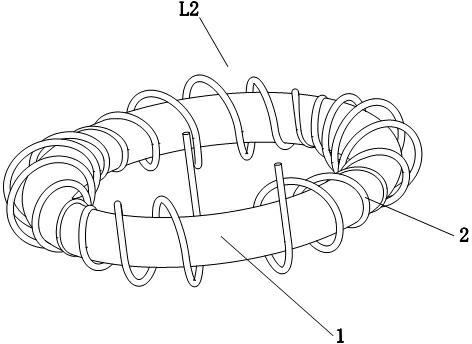

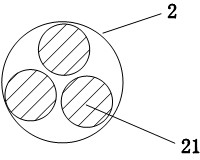

[0021] Such as figure 1 , figure 2 As shown, the power choke coil L2 of this embodiment includes an annular magnetizer 1 and a coil winding 2 surrounding the annular magnetizer. The outer surface of the annular magnetizer is coated with an insulating layer. Stranded.

[0022] The diameter of the enameled wire 21 is less than 0.6mm. The annular magnetizer 1 is made of ferrite material. The annular magnetizer is a closed loop.

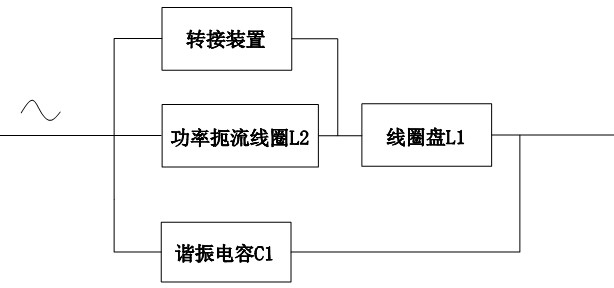

[0023] Such as image 3 , Figure 4 As shown, this embodiment also discloses an electromagnetic induction heating device, which includes a parallel coil disk L1 and a resonant capacitor C1, and the power choke coil L2 is connected in series between the coil disk L1 and the resonant capacitor C1. The two ends of the power choke coil L2 are connected with a switching device S1.

[0024] In this embodiment, the switching device S1 is a single-pole single-throw relay.

Embodiment 2

[0026] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the switching device S1 is a single-pole double-throw relay. Other structures are the same as in Embodiment 1.

Embodiment 3

[0028] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the annular magnetizer is made of silicon steel, and there is a gap of 3 mm in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com