Micro-channel heat exchanger and heat pump system

A technology of microchannel heat exchangers and headers, applied in indirect heat exchangers, heat exchanger types, heat pumps, etc., can solve the problem of frosting and icing on the surface of heat exchangers, and microchannel heat exchangers do not apply , Condensed water is not easy to discharge and other problems, to achieve the effect of solving surface frosting and icing, solving uneven heat transfer, and increasing circulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

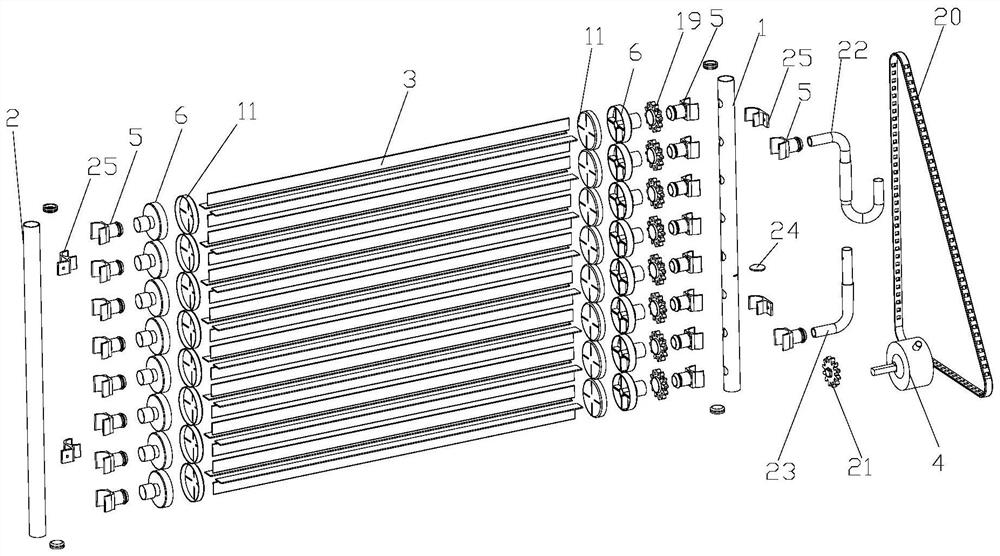

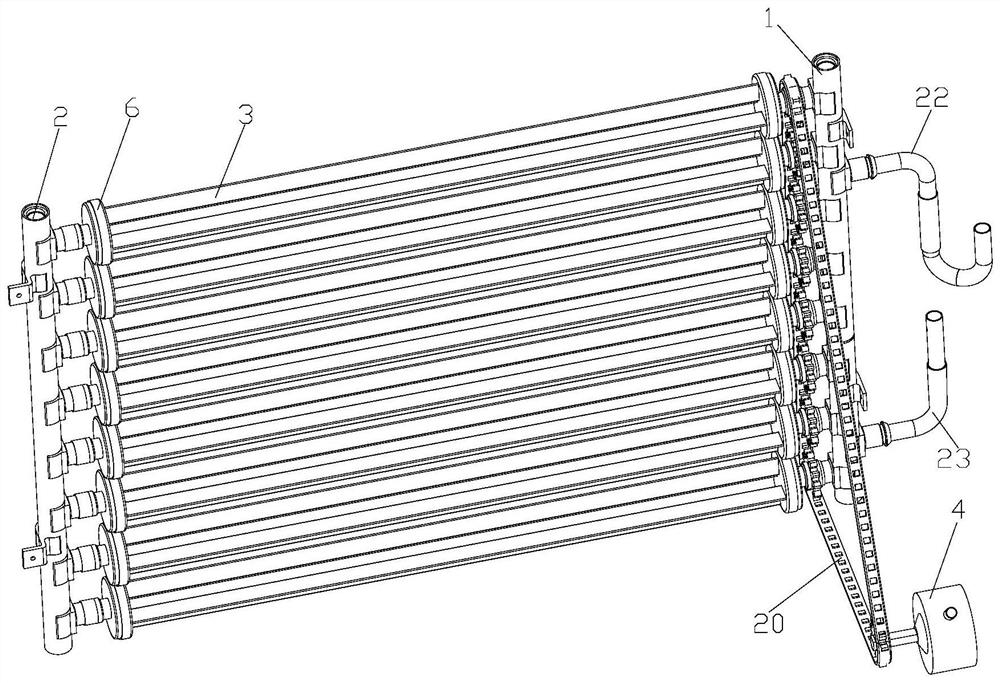

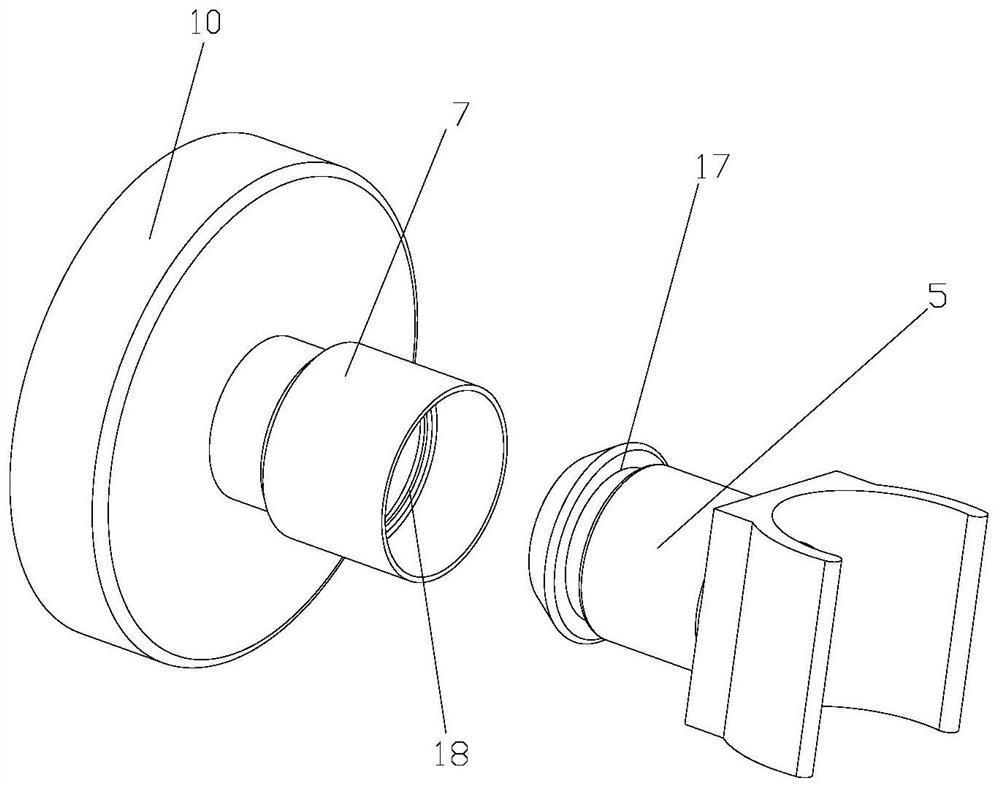

[0033] see in conjunction Figure 1 to Figure 8 As shown, according to the embodiment of the present application, the microchannel heat exchanger includes a first header 1, a second header 2, a rotating connection assembly and a flat tube 3, and the first end of the flat tube 3 is connected to the first header The tube 1 communicates, the second end of the flat tube 3 communicates with the second header 2, the first end of the flat tube 3 can be rotatably connected with the first header 1 through a rotating connection assembly, and the second end of the flat tube 3 The end can be rotatably connected with the second header 2 through a rotatable connection assembly.

[0034] In the microchannel heat exchanger of the present application, since the flat tube 3 and the header are rotatably connected by a rotating connection assembly, the flat tube 3 can rotate relative to the header. During operation, when the microchannel heat exchanger When used as an evaporator, the water bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com