Zinc-copper negative electrode, preparation method thereof and zinc ion battery

A zinc-ion battery, zinc-copper technology, applied in electrode manufacturing, secondary batteries, circuits, etc., can solve the problems of poor stability and short cycle life of zinc-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing a zinc-copper negative electrode 100, comprising the following steps:

[0041] Step S1: providing a zinc current collector 10; and

[0042] Step S2: Coating the copper film 30 on the zinc current collector 10 .

[0043]The thickness of the copper film 30 ranges from 1 μm to 15 μm. For example, it is 1 μm, 3 μm, 5 μm, 7 μm, 9 μm, 10 μm, 12 μm, 14 μm, or 15 μm.

[0044] In the technical solution of the present invention, since the copper film 30 covers the zinc current collector 10, in the process of charging and discharging, the dissolution of zinc and the deposition of zinc ions on the surface of the zinc current collector 10 will not be repeated, but It is to repeatedly deposit zinc ions and dissolve zinc on the surface of the copper film 30, and the morphology of the copper film 30 does not change, so that zinc dendrites will not be formed on the surface of the copper film 30, avoiding the formation of zinc ...

Embodiment 1

[0066] Provided at a concentration of 0.5mol L -1 copper sulfate solution;

[0067] Soak the zinc sheet (1.2 cm in diameter) in the copper sulfate solution for 10 seconds, then take it out, and rinse it with deionized water to obtain the zinc-copper negative electrode of Example 1;

[0068] Provide positive electrode, the concentration is 2mol L -1 Zinc sulfate aqueous solution, and glass fiber isolation film. Wherein, the positive electrode film of the positive electrode contains vanadium dioxide, acetylene black, and polytetrafluoroethylene, and the mass ratio of the three is 7:2:1;

[0069] The zinc-copper negative electrode, positive electrode, zinc sulfate aqueous solution, and glass fiber separator of Example 1 were assembled into the zinc-ion battery of Example 1.

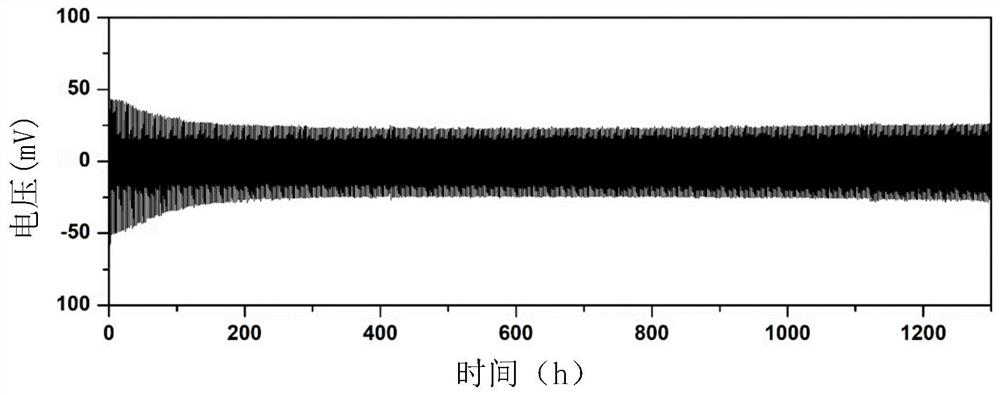

[0070] figure 2 It is the voltage-time curve of the zinc ion battery of Example 1 under constant current conditions. where the current density is 0.5mA cm -2 , the deposition amount per circle is 0.5m...

Embodiment 2

[0077] Different from Example 1, the concentration of copper sulfate is 1mol L -1 .

[0078] Other steps are the same as those in Embodiment 1 and will not be repeated here.

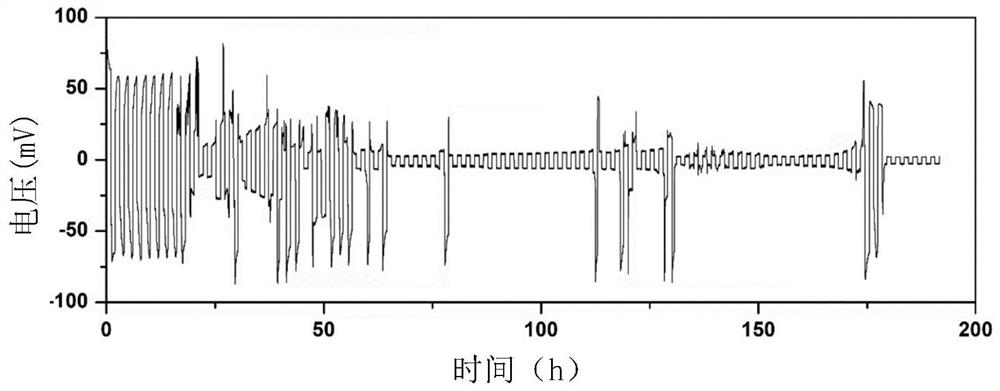

[0079] Figure 5 It is the voltage-time curve of the zinc ion battery of Example 2 under constant current conditions. where the current density is 0.5mA cm -2 , the deposition amount per circle is 0.5mAh cm -2 . The results show that the zinc ion battery of Example 2 has better stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com