Bus extension butt joint structure and GIS

A busbar and joint technology, applied in the field of busbar extension docking structure and GIS, can solve problems such as power outages in power stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

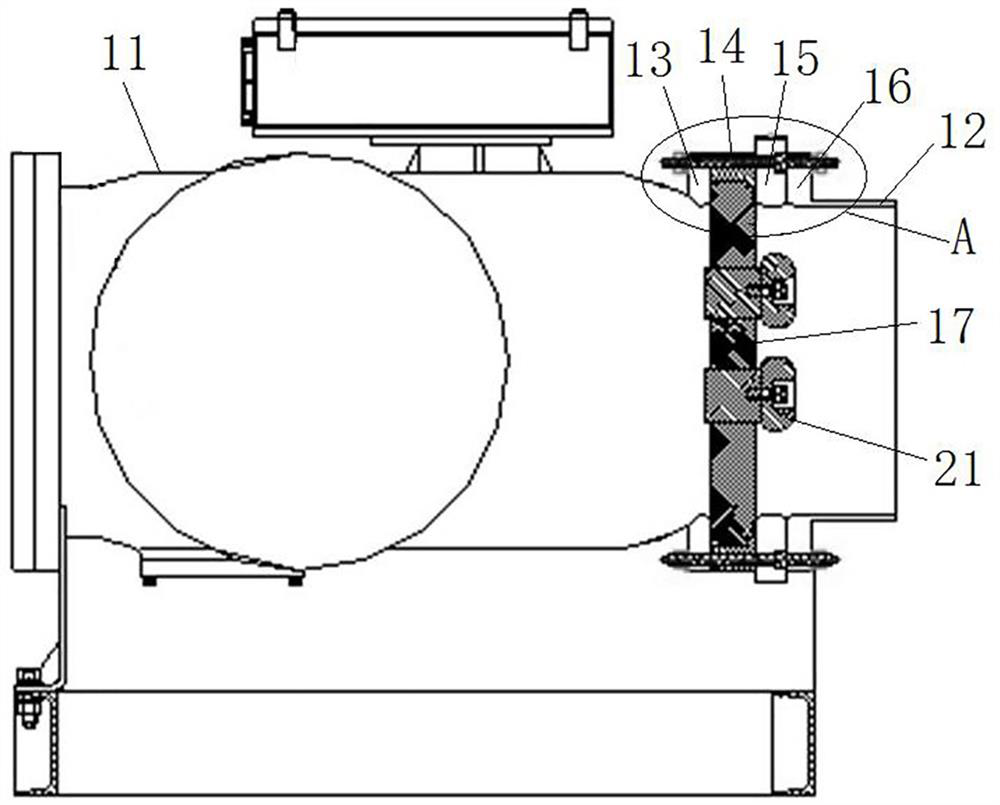

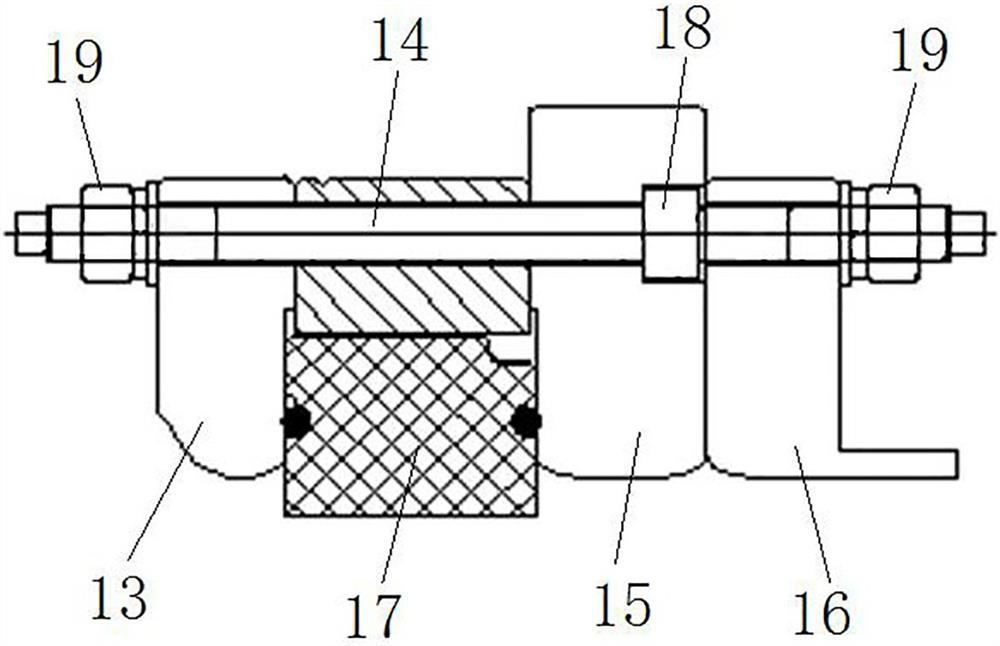

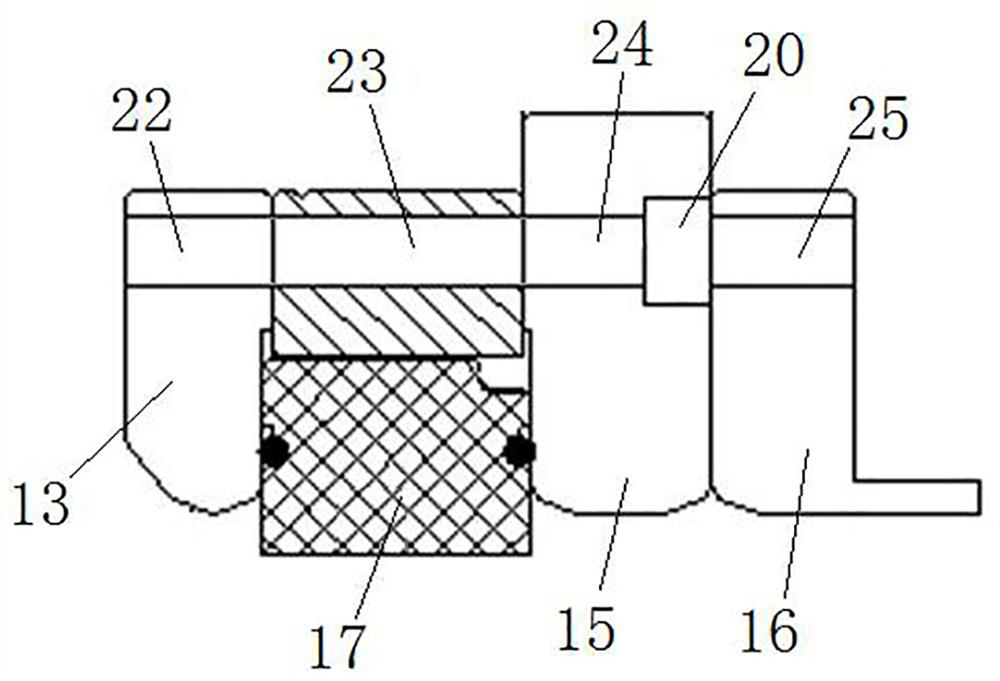

[0048] like figure 1 and figure 2 As shown, the GIS includes an isolation and grounding switch. The isolation and grounding switch includes a cylinder body 11, an insulator 17, a flange ring 15 and an end cap 12 are arranged in sequence on the right side of the cylinder body 11, and the cylinder body 11, the insulator 17, the flange ring 15 and the The end caps 12 are fixedly connected together by a screw 14 .

[0049] like figure 1 and image 3 As shown, the right end of the cylinder body 11 is provided with a first connecting flange 13, the first connecting flange 13 is provided with a plurality of first flange holes 22, the left end of the end cap 12 is provided with a second connecting flange 16, and The second connecting flange 16 is provided with a plurality of second flange holes 25 .

[0050] In this embodiment, the insulator 17 is arranged between the first connecting flange 13 and the second connecting flange 16, that is, between the cylinder body 11 and the end...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the annular protrusion 18 and the screw 14 are integrally formed. In this embodiment, the annular protrusion is a nut, and the annular protrusion is threadedly connected to the screw rod.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the position-limiting protrusion is an annular protrusion. In this embodiment, there are multiple limiting protrusions, and the limiting protrusions are arranged at intervals along the circumferential direction of the screw rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com