Motor connection buffer device capable of resisting multi-axial high overload

A buffer device and high overload technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as motor installation and connection problems, and achieve the effect of high overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

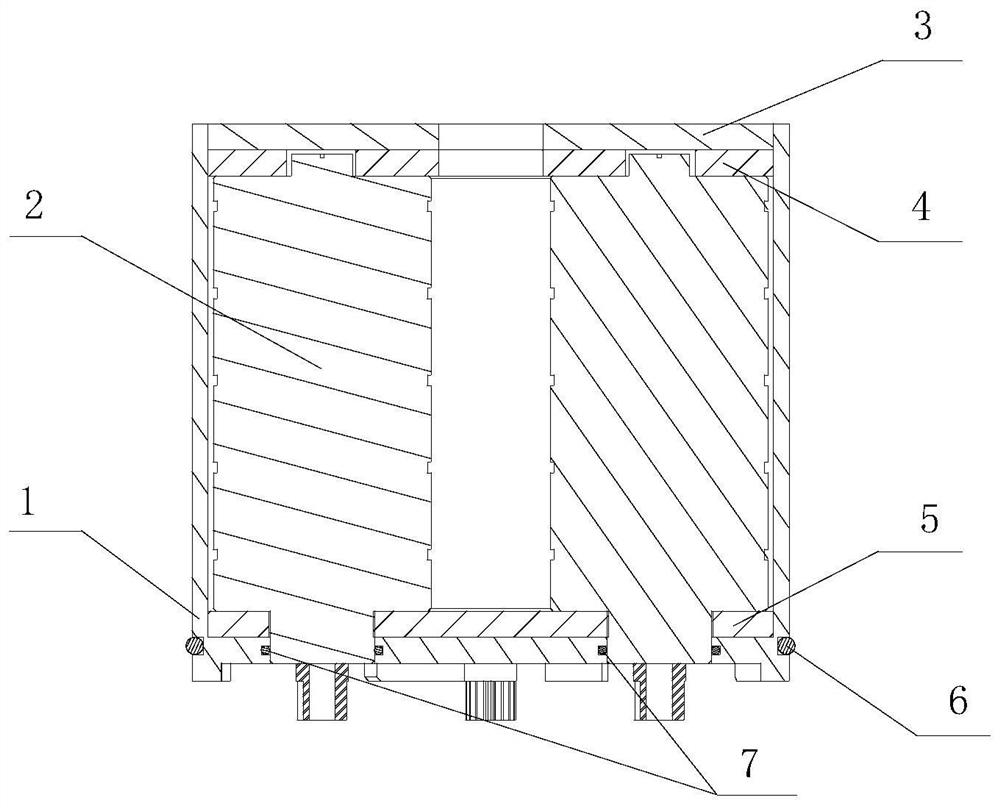

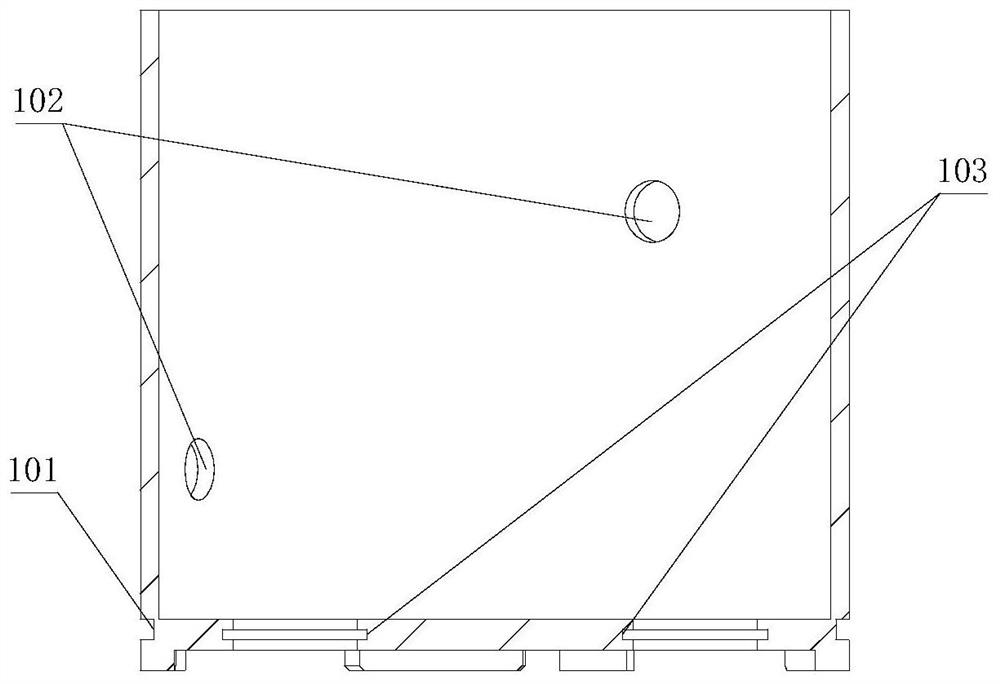

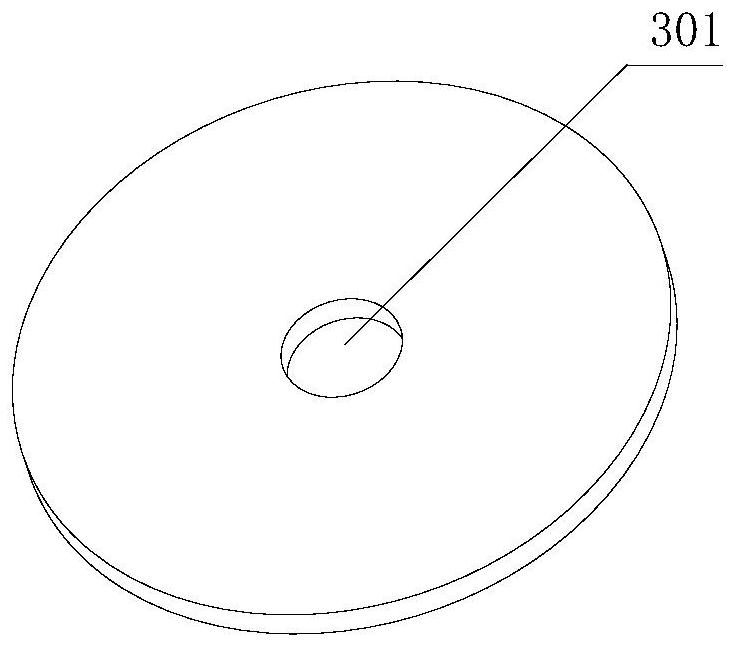

[0018] According to the following Figure 1 ~ Figure 4 , the preferred embodiment of the present invention is described in detail.

[0019] The present invention provides a multi-axial high overload resistance motor 2 connection buffer device, comprising an integrated frame 1 , a motor 2 , a locking cover 3 , an upper damping pad 4 , and a lower damping pad 5 . The bottom sealing ring 6 and the outer sealing ring 7 of the integrated frame 1 prevent the glue liquid from flowing out from the bottom of the frame during potting, so as to realize the isolation of the potting glue and the transmission device.

[0020] The motor 2 is connected with the integrated frame 1, the tail of the motor 2 is fastened by the locking cover plate 3, and the vibration damping pads are respectively installed between the motor 2 and the integrated frame 1 and between the motor 2 and the locking cover plate 3. 4 and the lower vibration damping pad 5.

[0021] The integrated frame 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com