Concave grate structure and combine harvester

A technology of concave screen and frame, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of crop loss, short screening path of concave screen, etc., achieve compact layout, improve mobility and threshing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

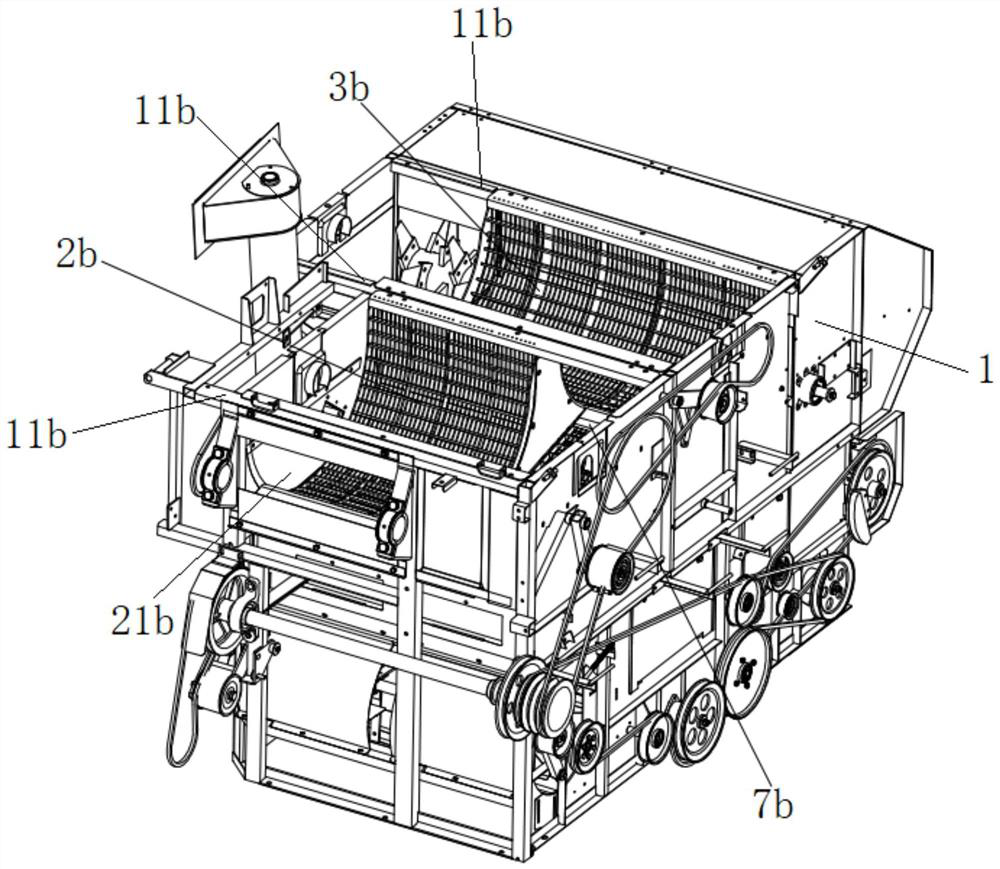

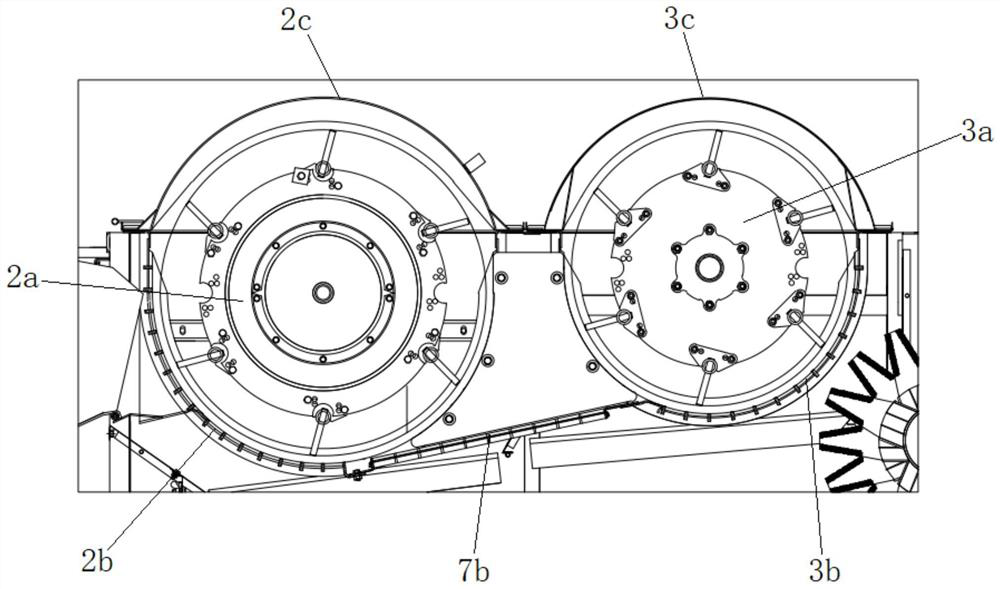

[0045] This embodiment provides a concave sieve structure, including two concave sieves, respectively a first concave sieve 2b with a feed opening 21b and a second concave sieve adjacent to the first concave sieve 2b in the crop conveying direction. The concave screen 3b, the first concave screen 2b and the second concave screen 3b have the same length, that is, the screening area has the same length. The inner screen surface of each concave screen is arc-shaped, and the axes of the two concave screens are parallel to each other, and are fixed on the frame 1 at intervals along the horizontal direction.

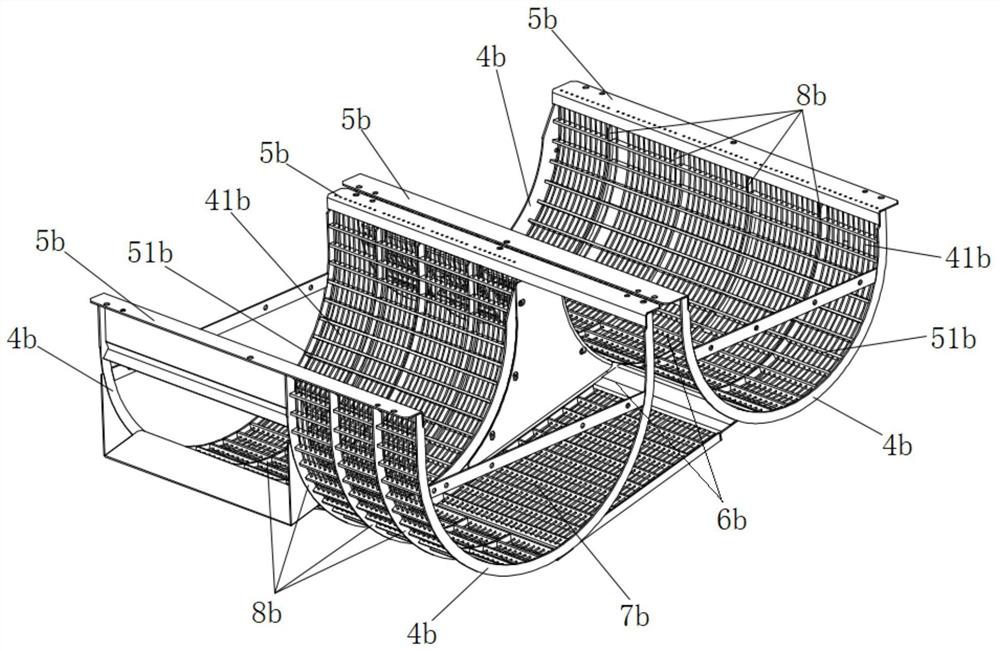

[0046] Such as figure 1 As shown, each concave screen includes two side guard plates 4b, two connecting beams 5b, multiple grid bars 51b, multiple steel wires 41b and several reinforcing ribs 8b. The two side guard plates 4b are arc-shaped respectively. The side guard plates 4b are coaxial and oppositely arranged. The two ends of the two side guard plates 4b are welded and fi...

Embodiment 2

[0053] This embodiment provides a combine harvester, including the concave screen structure described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com