Alternate vertical filtration overflow water taking type desilting basin

A grit chamber and overflow technology, which is applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problem of sudden drop in the grit effect of the grit chamber, the sand content of the outlet pond meeting the water supply requirements, and affecting the normal operation of the water intake project, etc. problem, to avoid the accumulation of fine sand and ensure the effect of effective capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

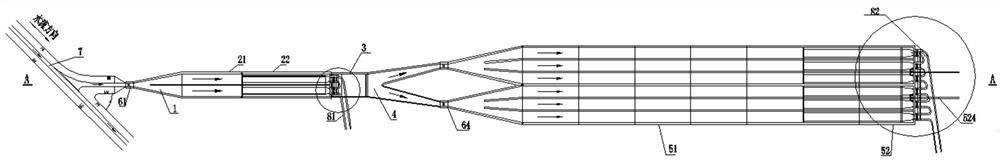

[0046] A kind of grit chamber of alternate vertical filter overflow water intake type, see Figure 1 ~ Figure 2 , including the first diffusion section 1, the primary grit chamber 2, the overflow section 3, the second diffusion section 4 and the secondary grit chamber 5 arranged in sequence according to the flow direction, the first diffusion section 1 and the second diffusion section 4 The cross-sections of the horns are trumpet-shaped, and the narrow mouth of the horn corresponds to the water inlet.

[0047] The middle part of the second diffusion section 4 is surrounded by a blocking wall to form a non-water flow area with a rhombus-shaped cross section, and one symmetrical axis of the rhombus is consistent with the direction of water flow, and the corresponding blocking wall at both ends of the other symmetrical axis and the corresponding first There is a gap between the side walls of the two diffusion sections 4 to form a pair of water outlets, and each water outlet is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com