Automatic riveting device for mechanical arm manufacturing

A technology of mechanical arm and driving device, which is applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc. It can solve the problems of mold offset, lack of automation, lack of cooling function, etc., and achieve the effect of prolonging the service life and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

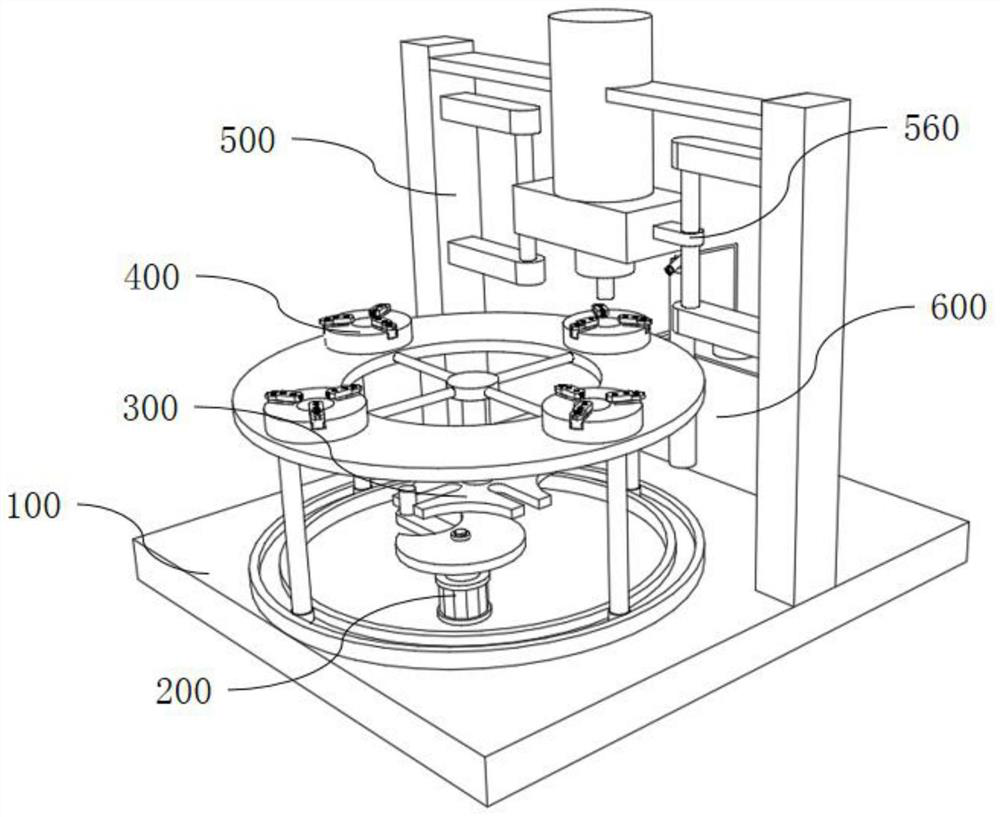

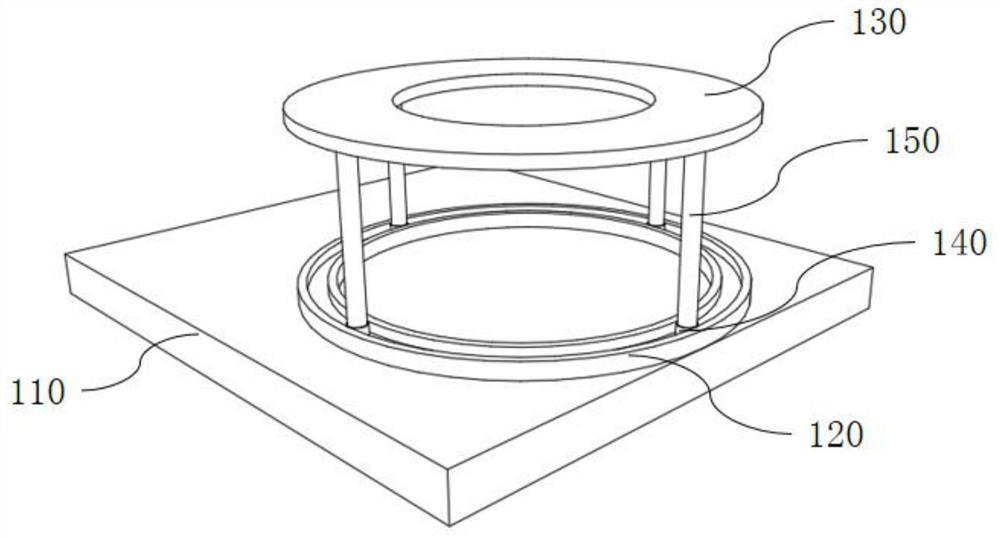

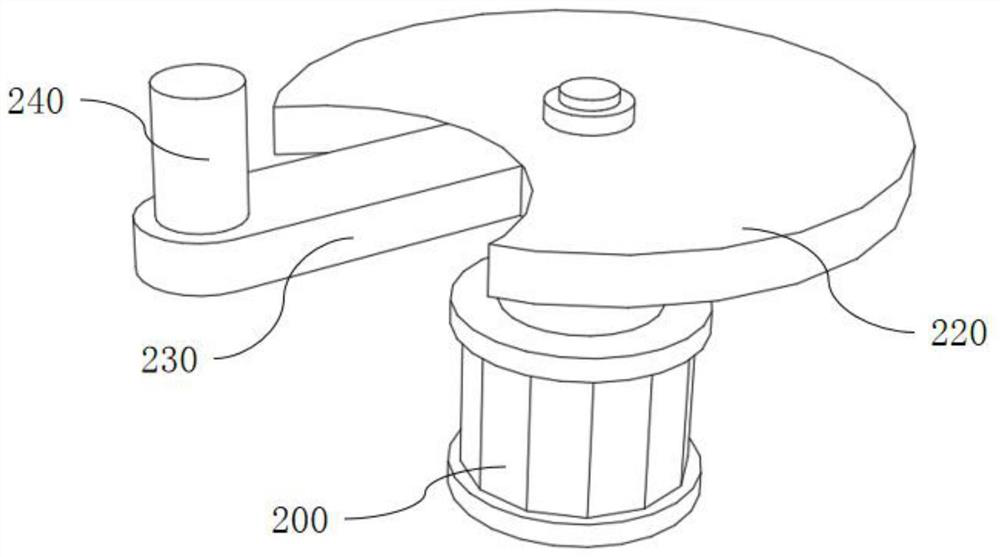

[0032] see Figure 1-7 As shown, the present invention is an automatic riveting device for manipulator manufacturing, including a base 100, a driving device 200, a rhythmic rotating device 300, a triangular chuck 400, a stamping device 500 and a cooling device 600, and the base 100 includes a bottom plate 110 and a reinforcement plate 130, the driving device 200 includes a driving motor 210 and a guide post 240, the lower surface of the driving motor 210 is welded to the upper surface of the bottom plate 110, the rhythm rotating device 300 includes a rotating seat 310, a fixed rod 340 and a rotating plate 350, and the upper surface of the rotating plate 350 is provided with There are several grooves, the guide column 240 is slidingly matched with several grooves, the lower surface of the rotating base 310 is welded to the upper surface of the bottom plate 110, one end of several fixed rods 340 is welded to the inner surface of the reinforcement plate 130, and the triangular chu...

Embodiment 2

[0041] see Figure 1-7 As shown in the present invention, by setting the driving device 200 and the rhythmic rotating device 300, the rotating plate 350 can be slotted according to the needs, and the size of the rotating plate 220 can be adjusted at the same time to adapt to the number of slots, and the guide column 240 can be slidably matched with the groove. To realize the rhythmic and regular rotation of the rotating rod 320, the number of triangular chucks should be consistent with the number of slots. By setting the triangular chuck 400 and the stamping device 500, the triangular chuck 400 is used to clamp the column device, and then The stamping device 500 can be used to carry out regular stamping. The working frequency of the stamping machine 520 should be adapted to the number of the triangular chucks 400, so as to achieve the purpose of automatic riveting and more automation. By setting the cooling device 600, the stamping is completed. Finally, since the stamping par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com