A kind of forging method of nb47ti alloy large-scale bar for superconducting wire

A superconducting wire, large-scale technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of cost increase, excessive forging fire times, etc., achieve shorten forging fire times, high-magnification structure Uniform and fine, cost-reducing effect

Active Publication Date: 2022-06-10

西部超导材料科技股份有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a method for forging large-scale Nb47Ti alloy rods for superconducting wires, which solves the problem of cost increase caused by too many forging fires in the prior art

Method used

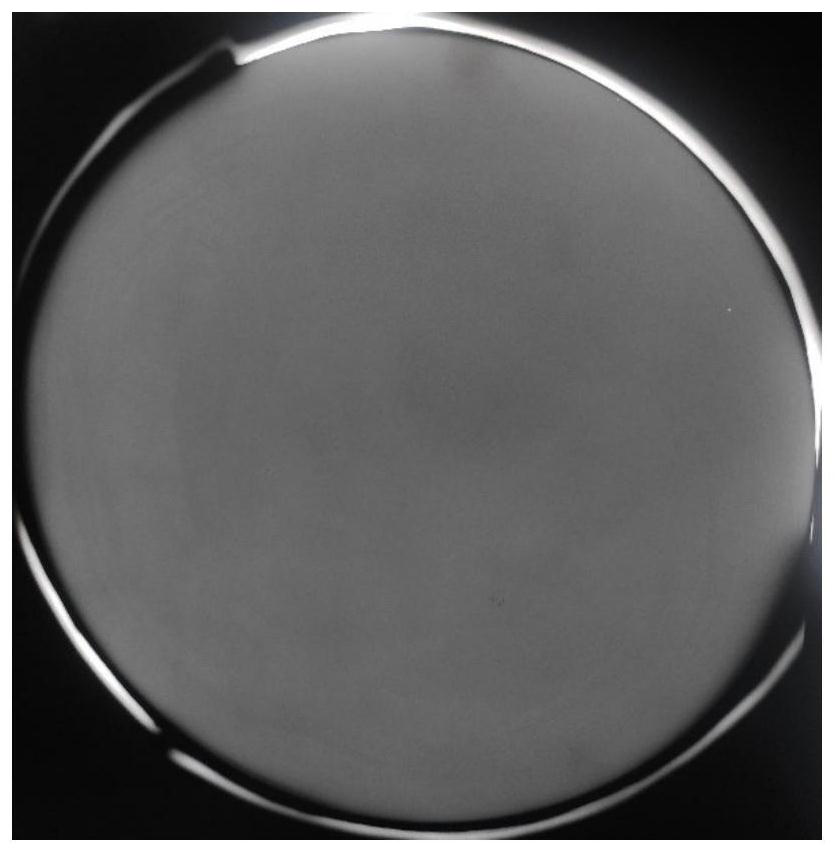

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

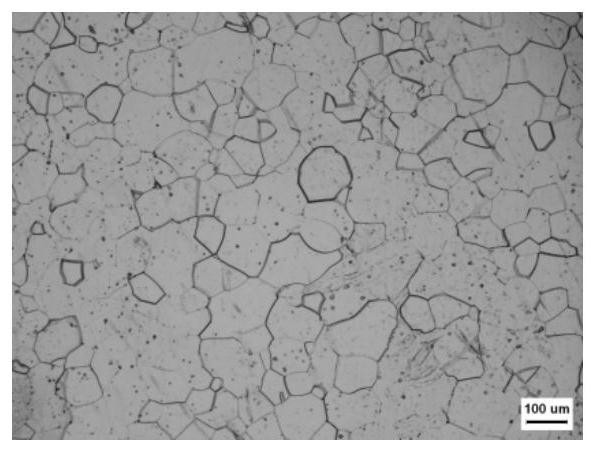

The invention discloses a method for forging large-scale Nb47Ti alloy rods for superconducting wires. Cooling; the Nb47Ti alloy ingot after forging is carried out for the second fire forging, the second fire forging process includes elongation, rounding, and cooling after forging; the Nb47Ti alloy ingot after the middle forging is forged by diameter Machine for the third fire forging, cooling after forging, to obtain Nb47Ti alloy large-size rods. By selecting the deformation method, deformation equipment and deformation amount, the forging fire times and production cycle are shortened, thereby reducing the cost, and large-scale Nb47Ti alloy large-scale rods with uniform and fuzzy structures at low magnifications and fine and uniform structures at high magnifications can be obtained.

Description

A kind of forging method of Nb47Ti alloy large-sized bar for superconducting wire technical field The invention belongs to non-ferrous metal processing method technical field, relate to a kind of Nb47Ti alloy large size for superconducting wire rod Bar forging method. Background technique Nb47Ti alloy rod is an important raw material for preparing superconducting wire, because the extremely harsh use of superconducting wire Therefore, high requirements are placed on the uniformity of the structure of the Nb47Ti alloy rod. Forging of traditional Nb47Ti alloy bars The ingot is sawed and cut, and after heating, the ingot is subjected to upsetting deformation for multiple fires, so as to improve the billet group. For the purpose of weaving uniformity, due to the more forging times and the longer production cycle, the production cost also increases. SUMMARY OF THE INVENTION The object of the present invention is to provide a kind of forging method of Nb47Ti alloy lar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21J5/00B21J5/06B21J5/08B21K29/00

CPCB21J5/00B21J5/06B21J5/08B21K29/00

Inventor 杨晶张胜张奕尚金金何龙龙李少强王凯旋刘向宏

Owner 西部超导材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com