Production method for controlling large-sized hard inclusions in spring steel wire rods

A technology for controlling springs and production methods, applied in the direction of manufacturing converters, improving process efficiency, etc., can solve the problems that the fatigue life of high-strength springs cannot be guaranteed, and the plastic deformation of inclusions cannot be guaranteed, so as to reduce the size of inclusions, oxidation The effect of reducing the diameter of inclusions and avoiding slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0032] Embodiment 1-8: The production method for controlling the large-sized hard inclusions in the spring steel wire rod is specifically described as follows.

[0033] (1) Production process: The above-mentioned process is used for production. The specific parameters of the process in each embodiment are shown in Table 1, and the slag composition of the LF refining process is shown in Table 2.

[0034] Table 1: The processing parameters of each embodiment

[0035]

[0036] Table 2: Slag composition of LF process (wt.%)

[0037]

[0038] (2) Product composition: The main chemical composition of the spring steel wire rod obtained in each embodiment is shown in Table 3, and the balance is Fe and unavoidable impurities.

[0039] Table 3: The main chemical composition (wt%) of each embodiment wire rod

[0040]

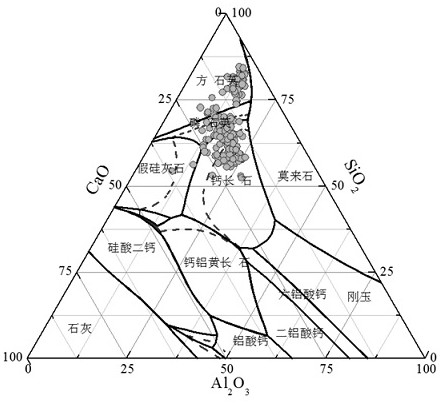

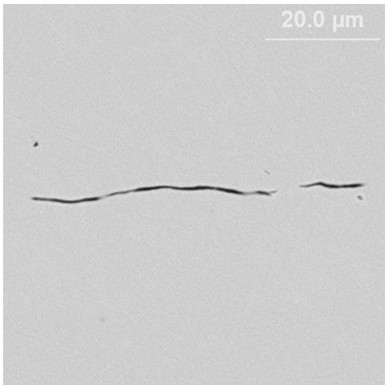

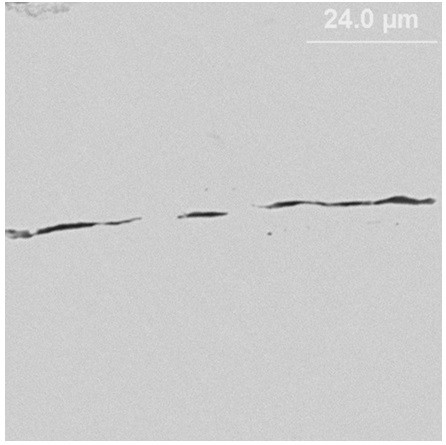

[0041] (3) Detection and analysis: Sampling the hot-rolled wire rod obtained by this method, and performing SEM-EDS detection and analysis on the inclusions in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com