Automatic riveting machine for continuous stamping

A riveting machine and automatic technology, applied in the field of riveting machines, can solve the problems of rivet punching offset, inability to fit effectively, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

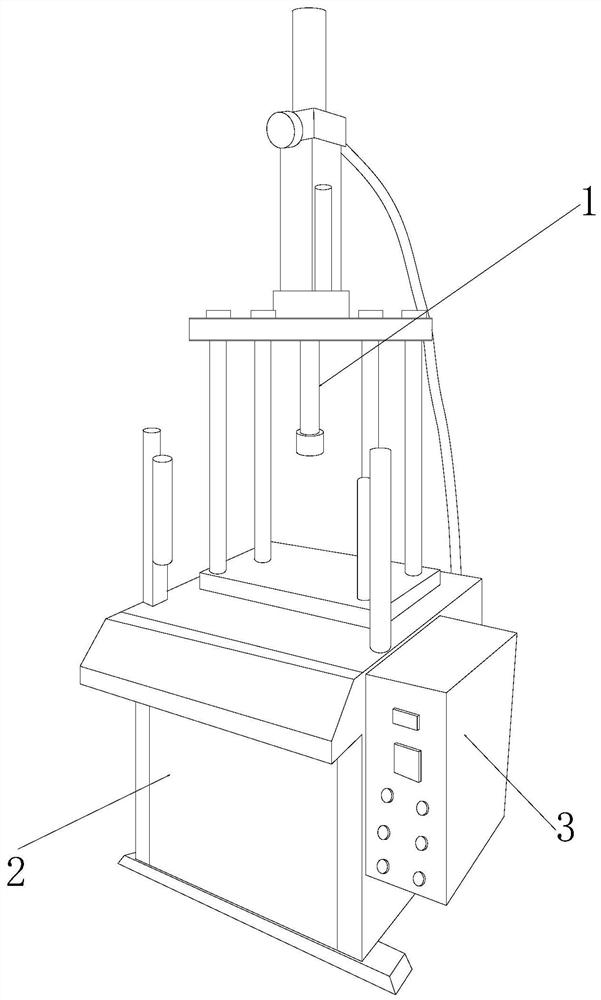

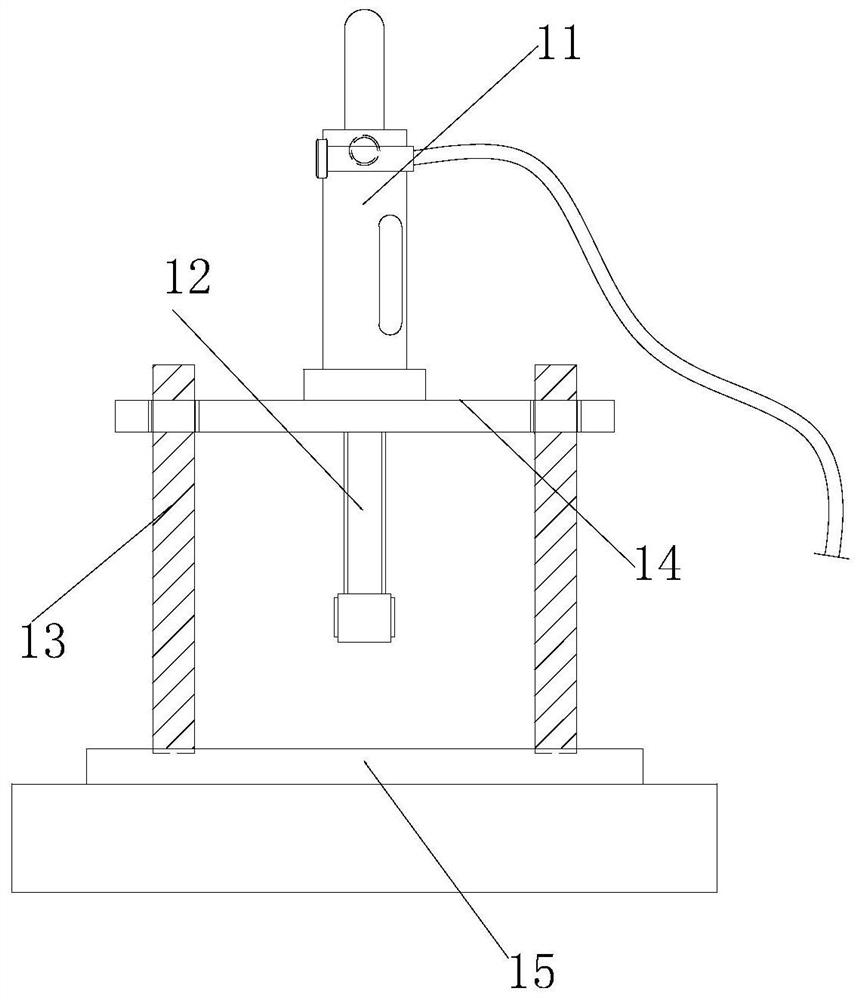

[0025] as attached figure 1 To attach Figure 5 Shown:

[0026] The invention provides an automatic riveting machine for continuous stamping, the structure of which includes a stamping device 1, a body 2, and a control box 3. A control box 3 is embedded and installed, and the control box 3 is located directly below the stamping equipment 1; the stamping equipment 1 includes a hydraulic device 11, a stamping rod 12, a lifting column 13, a movable plate 14, and a fixed platform 15. The device 11 is inlaid directly above the stamping rod 12, and the stamping rod 12 is embedded and installed directly above the fixed platform 15. The lifting column 13 is inlaid on the inner surface of the left and right ends of the movable plate 14. The movable plate 14 The inlay is installed directly above the fixed platform 15 , and the fixed platform 15 is located directly below the hydraulic unit 11 .

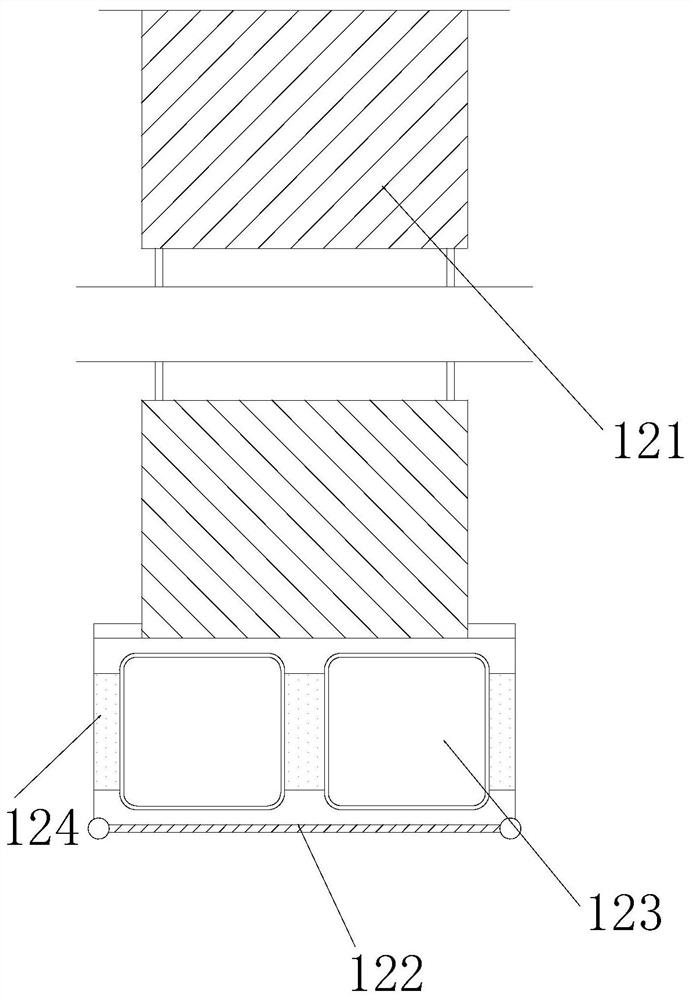

[0027] Wherein, the stamping rod 12 includes a vibrating rod 121, a wrapping mechanism 12...

Embodiment 2

[0032] as attached Figure 5 To attach Figure 7 Shown:

[0033] Wherein, the movable mechanism 221 includes a bidirectional shaft 211, a rubber wrapping sheet 212, an adsorption mechanism 213, and a second hollow block 214. The bidirectional shaft 211 is movably engaged on the inner upper end surface of the movable mechanism 221, and the rubber wrapping sheet 212 Fitted and wrapped on the outer end surface of the bidirectional shaft 211, the adsorption mechanism 213 is embedded directly under the second hollow block 214, and the second hollow block 214 is embedded and mounted on the inner end surface of the movable mechanism 221. The outer end surface of the second hollow block 214 is wrapped with rubber material, which can make it rebound with its own rubber material after being deformed by the extrusion of 212 .

[0034]Wherein, the bidirectional shaft 211 includes an inlaid shaft 111, a movable shaft 112, a movable groove 113, and an inlaid connecting plate 114. The inla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com