Intelligent delivery system device based on positioning, moving and discharging and control system thereof

A technology of mobile blanking and system equipment, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of poor cooperation between the operator and the driver, failure to adopt, troublesome process, etc., and achieve precise and error-free blanking drive control operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

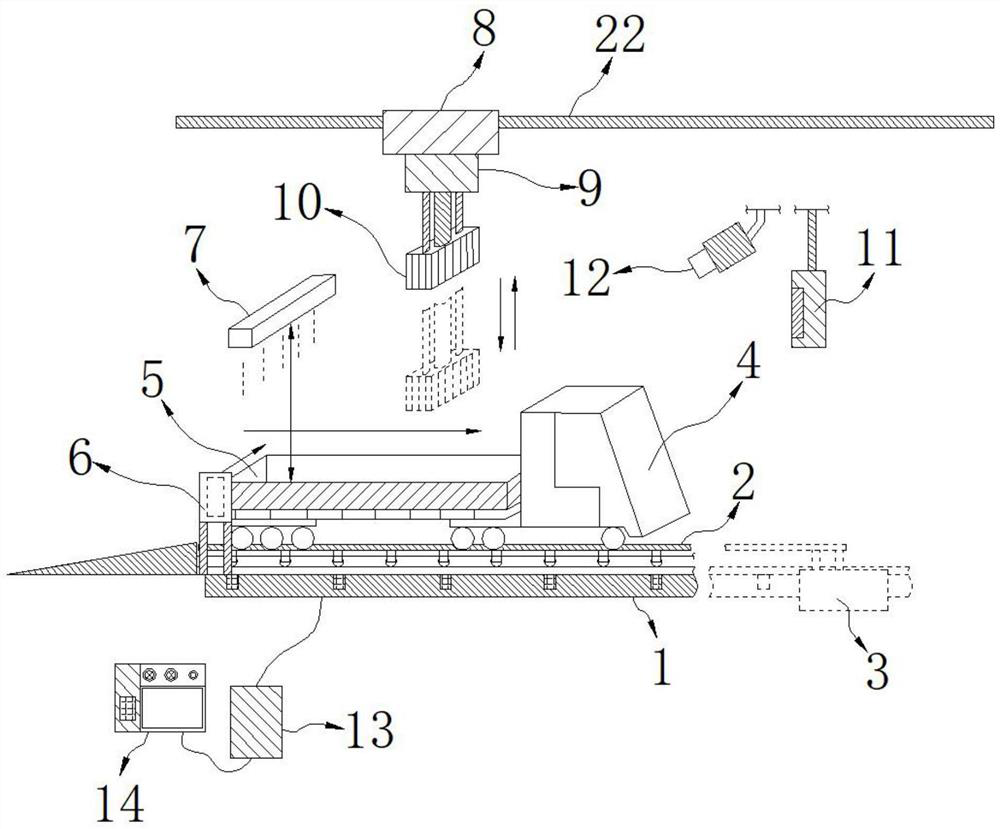

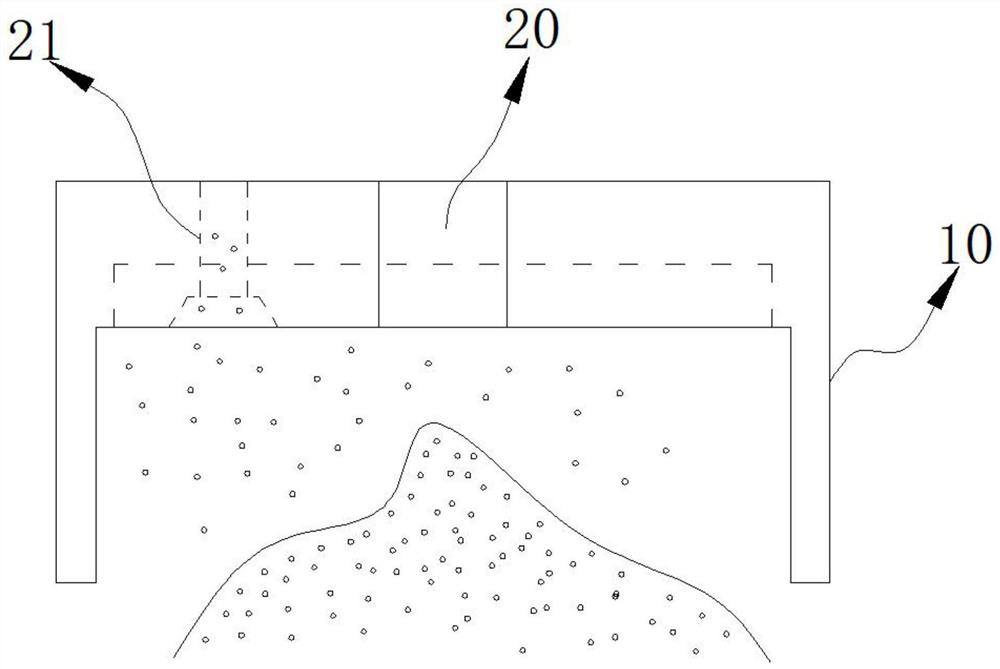

[0042]Automatic device working principle among the present invention:

[0043] On the existing weighbridge of the clinker warehouse, high-density steel guide rails and rollers are laid according to the length of the weighbridge, and the bearing mechanism is erected on it. The total height is about 300mm, and the bearing capacity and traction force exceed 200 tons.

[0044] The specific control process is as follows:

[0045] (1) The driver parks the vehicle in place according to the monitoring display screen and indicator lights.

[0046] (2) The driver selects the loading tonnage and loading mode on the touch screen and presses the start button.

[0047] (3) The detection system automatically detects the size of the carriage and displays it on the touch screen, and at the same time calculates the number of times of cutting.

[0048] (4) After the detection is completed, the system automatically locates the relative position of the carriage and the unloading mechanism.

[0...

Embodiment 2

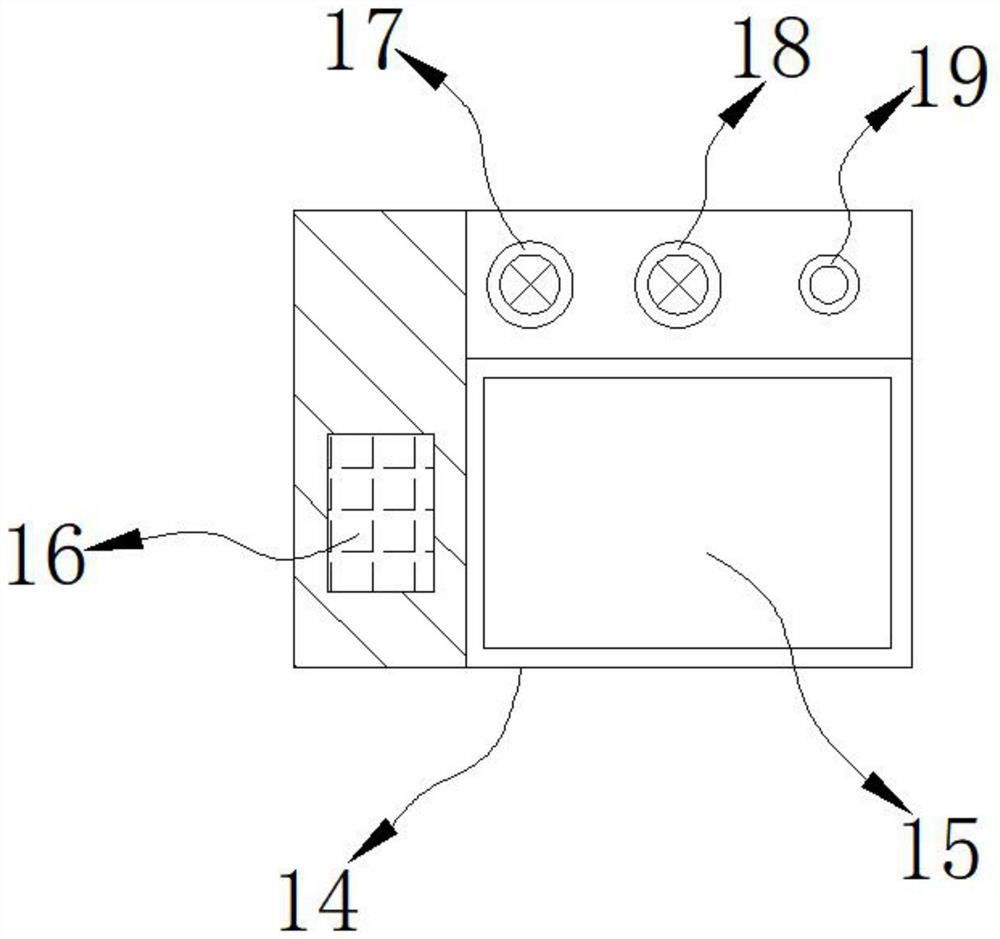

[0059] In the present invention, a track-type weighing system can be used, and the advantages of various measuring equipments on the market can be integrated, and it can be constructed and installed in various occasions according to local conditions.

[0060] 1. The equipment adopts the combination of track and roller moving mode and mature platform weighing structure, which completely solves the problem of mobile weighing.

[0061] 2. Diversified installation methods, ground or semi-underground installation methods are available, and different installation methods can be selected according to the actual situation on site.

[0062] 3. The measurement accuracy reaches ±0.2%, and the compliance rate is 100%; there is no requirement for the discharge flow, flow rate and storage pressure. Within the flow range of 1t / h-1000t / h, the measurement accuracy of ±0.2% can be achieved.

[0063] 4. Using high-precision waterproof and dustproof sensors, it can be used in any occasion.

[0...

Embodiment 3

[0068] During the actual installation of the weighbridge mechanism and the traction mechanism of the device of the present invention:

[0069] 1. Ground load-bearing foundation construction, excavating 16 foundation pits of 1000mm*1000mm*1000mm on the ground, 300mm gravel cushion, and 500mmC20 concrete reinforcement foundation.

[0070] 2. A single 20t bridge load cell is installed on the basis.

[0071] 3. A 20mm thick load-bearing base steel plate is installed above the sensor, and the plates are connected by bolts.

[0072] 4. Lay the track, and install the roller car tray and the traction mechanism on the track.

[0073] 5. A small control room of 2 square meters is installed next to the installation station, and an electric control cabinet is installed for dust-free operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com