Iron tailing concrete and preparation method thereof

A technology of concrete and iron tailings, which is applied in the field of iron tailings concrete and its preparation, can solve the problems of low utilization rate of iron tailings, and achieve the effects of good workability, expanded utilization range, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

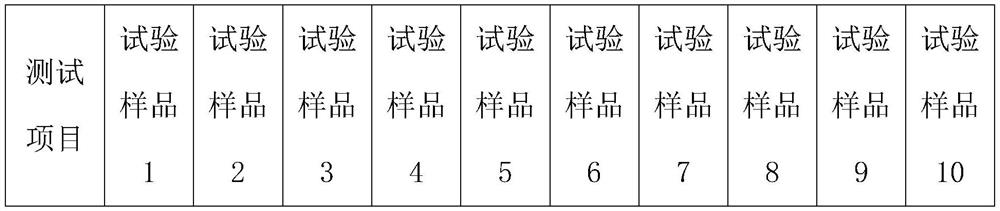

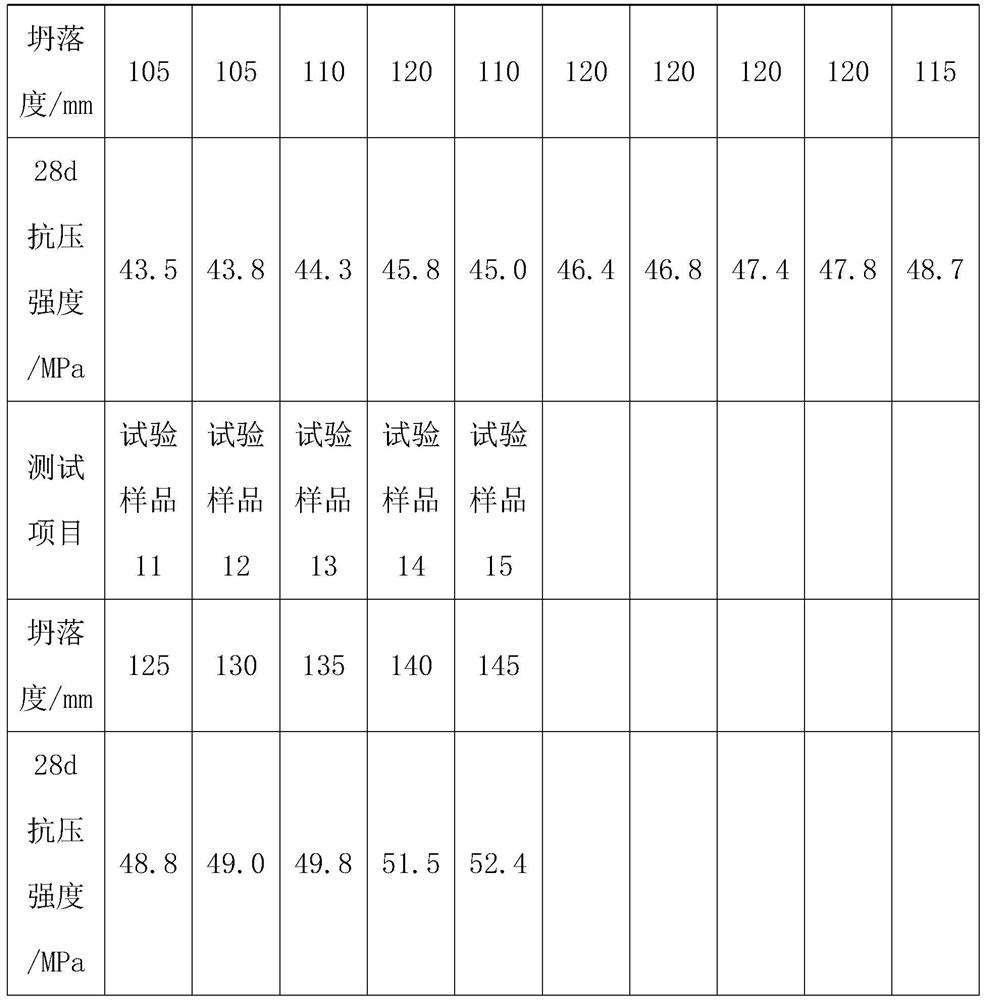

Examples

preparation example 1

[0040] Soak the desulfurized gypsum powder in a sodium hydroxide solution with a mass concentration of 10% for 90 minutes, and then dry it with a rotary drum dryer at a temperature of 80 degrees Celsius to obtain a modified desulfurized gypsum powder with a moisture content of 5%.

preparation example 2

[0042]The desulfurized gypsum powder was soaked in a sodium hydroxide solution with a mass concentration of 15% for 75 minutes, and then dried by a rotary drum dryer at a temperature of 70 degrees Celsius to obtain a modified desulfurized gypsum powder with a moisture content of 8%.

preparation example 3

[0044] The desulfurized gypsum powder is soaked in a sodium hydroxide solution with a mass concentration of 20% for 60 minutes, and then dried by a rotary drum dryer at a temperature of 60 degrees Celsius to obtain a modified desulfurized gypsum powder with a moisture content of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap