Method for preparing 2, 3-dimethyl thioanisole

A technology of dimethyl anisole and dimethyl disulfide, which is applied in the field of fine chemical intermediate synthesis, can solve the problems of cumbersome post-processing, high consumption and high cost, avoid post-processing steps, simplify processes, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

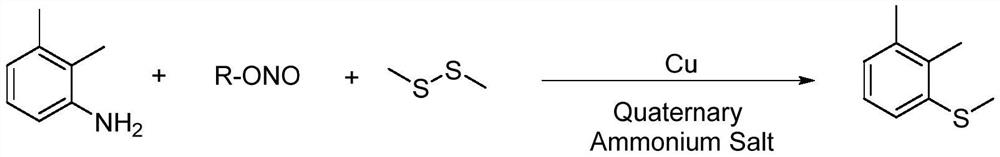

Method used

Image

Examples

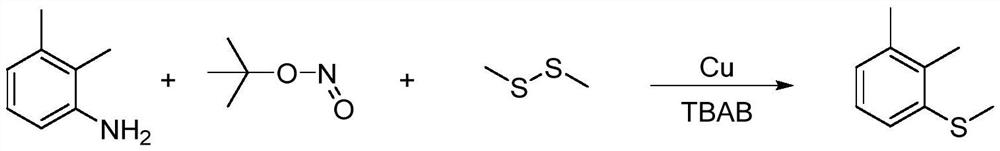

Embodiment 1

[0037] In a 250mL four-necked flask, add 2.57g (0.04mol, 99.5%) copper powder, 0.5g tetrabutylammonium bromide (TBAB), 56.97g (0.6mol, 99%) dimethyl disulfide , stirred, and the reaction temperature was controlled to be 20°C, and 17.35g (0.16mol, 95%) of tert-butyl nitrite was added dropwise for 0.5 hours. , 99%) 2,3-dimethylaniline, the dropping time is 1.5 hours, after the dropping, the temperature is raised to 50°C, reacted for 4 hours, sampling is carried out in the gas chromatography, and the content of 2,3-dimethylaniline is less than 0.2 %, stop the reaction. The reaction process can be represented by the following reaction equation:

[0038]

[0039] The reaction material was cooled to 25°C, filtered, and the residue was washed twice with dimethyl disulfide, and the amount of dimethyl disulfide was 10 g each time. The organic phases were combined and desolvated under reduced pressure at a vacuum of 4KPa. 15.69 g of crude product was obtained, the quantitative cont...

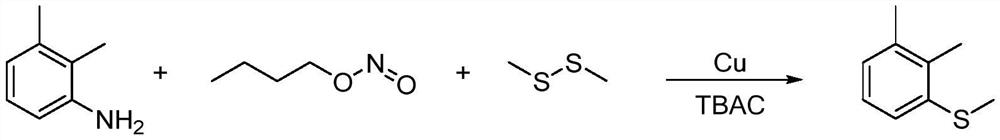

Embodiment 2

[0041]In a 250mL four-necked bottle, add 6.43g (0.1mol, 99.5%) copper powder, 0.12g tetrabutylammonium chloride (Tetrabutylammonium chloride, TBAC), 23.74g (0.25mol, 99%) dimethyl disulfide , stirred, and the reaction temperature was controlled to be 30°C, and 21.68g (0.2mol, 95%) of n-butyl nitrite was added dropwise for 0.5 hours. After the addition, the temperature was raised to 60°C, 12.22g (0.10mol , 99%) 2,3-dimethylaniline, the dropping time is 0.5 hours, after the drop is completed, the temperature is raised to 75 ° C, and the reaction is carried out for 2 hours, and the sample is controlled by gas chromatography, and the content of 2,3-dimethylaniline is less than 0.2 %, stop the reaction. The reaction process can be represented by the following reaction equation:

[0042]

[0043] The reaction material was cooled to 25°C, filtered, and the residue was washed twice with dimethyl disulfide, and the amount of dimethyl disulfide was 10 g each time. The organic phases...

Embodiment 3

[0045] In a 250mL four-necked bottle, add 0.64g (0.01mol, 99.5%) copper powder, 0.12g tetrabutylammonium iodide (Tetrabutylammonium iodide), 23.74g (0.25mol, 99%) dimethyl disulfide, stir , control the reaction temperature to be 10°C, add 13.01g (0.12mol, 95%) of n-butyl nitrite dropwise, the time for adding is 1.5 hours, after the addition, the temperature is raised to 40°C, and 12.22g (0.10mol, 99% %) 2,3-dimethylaniline, the dropping time is 1.5 hours, after the dropping is completed, the temperature is raised to 50°C, and the reaction is carried out for 4 hours, the sample is controlled by gas chromatography, the content of 2,3-dimethylaniline is less than 0.2%, Stop responding. The reaction process can be represented by the following reaction equation:

[0046]

[0047] The reaction material was cooled to 25°C, filtered, and the residue was washed twice with dimethyl disulfide, and the amount of dimethyl disulfide was 10 g each time. The organic phases were combined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com