Membrane column using novel upper flange and pressing sleeve

A compression sleeve and flange technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of installation difficulty, weight increase, membrane column performance deterioration, etc., to reduce the difficulty of installation and maintenance, reduce The effect of weight, improved longevity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

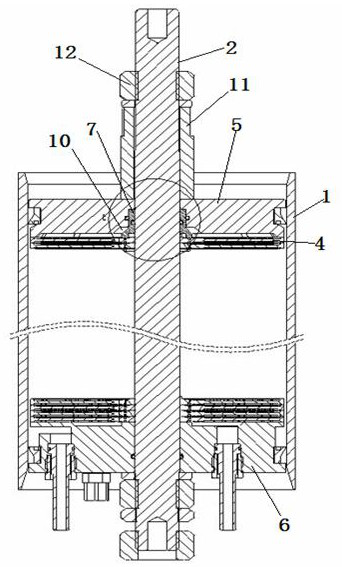

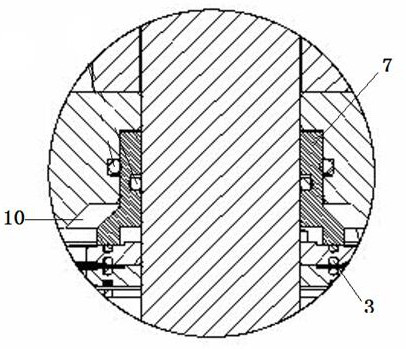

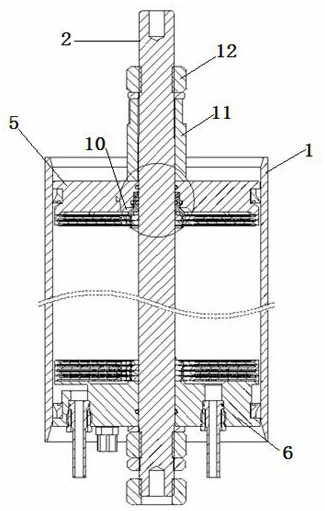

[0018] combine figure 1 , figure 2 As shown, a membrane column using a new type of upper flange and a compression sleeve includes a membrane housing 1, a central tie rod 2, a number of guide plates 4 with O-rings 3 installed on the center tie rod, and upper and lower ends of the center tie rod. The lower flange 5, 6, the upper section of the inner hole of the upper flange 5 is sealed with the center tie rod, and the lower section of the inner hole of the upper flange and the center tie rod reserve a space, and a compression sleeve 7 is installed in the space, and the bottom of the compression sleeve 7 The end presses the O-ring 3 of the guide plate, the top of the compression sleeve is in contact with the upper flange, and the compression sleeve 7 is sealed with the center tie rod 2 and the upper flange 5 through the sealing ring 8 . A gap 10 remains between the bottom outer wall of the compression sleeve 7 and the inner hole of the upper flange. The surface adjacent to the...

Embodiment 2

[0021] A membrane column using a new type of upper flange and a compression sleeve, including a membrane shell 1, a center tie rod 2, a number of guide plates 4 with O-rings 3 installed on the center tie rod, and upper and lower flanges at both ends of the center tie rod 5, 6, the upper section of the inner hole of the upper flange 5 is sealed with the center tie rod, the lower section of the inner hole of the upper flange 5 and the center tie rod 2 reserve a space 10, and the space 10 is equipped with a compression sleeve 7 and a disc spring 9, and the compression The bottom end of the cover presses the O-ring of the guide plate, the disc spring 9 is located between the top of the compression sleeve 7 and the upper flange 5, and the inner wall of the compression sleeve 7 is sealed with the central pull rod 2. A gap 10 remains between the bottom outer wall of the compression sleeve and the inner hole of the upper flange. The surface adjacent to the upper part of the compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com