Outer plate stamping forming machine for computer case production

A computer and forming machine technology, which is applied in the field of outer plate stamping and forming machines for the production of computer casings, can solve the problems of uneven stamping on the contact surface of the plate, affecting the quality of stamping, and high pressure, so as to improve the internal support effect and reduce the pressure. The production of small defective products and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

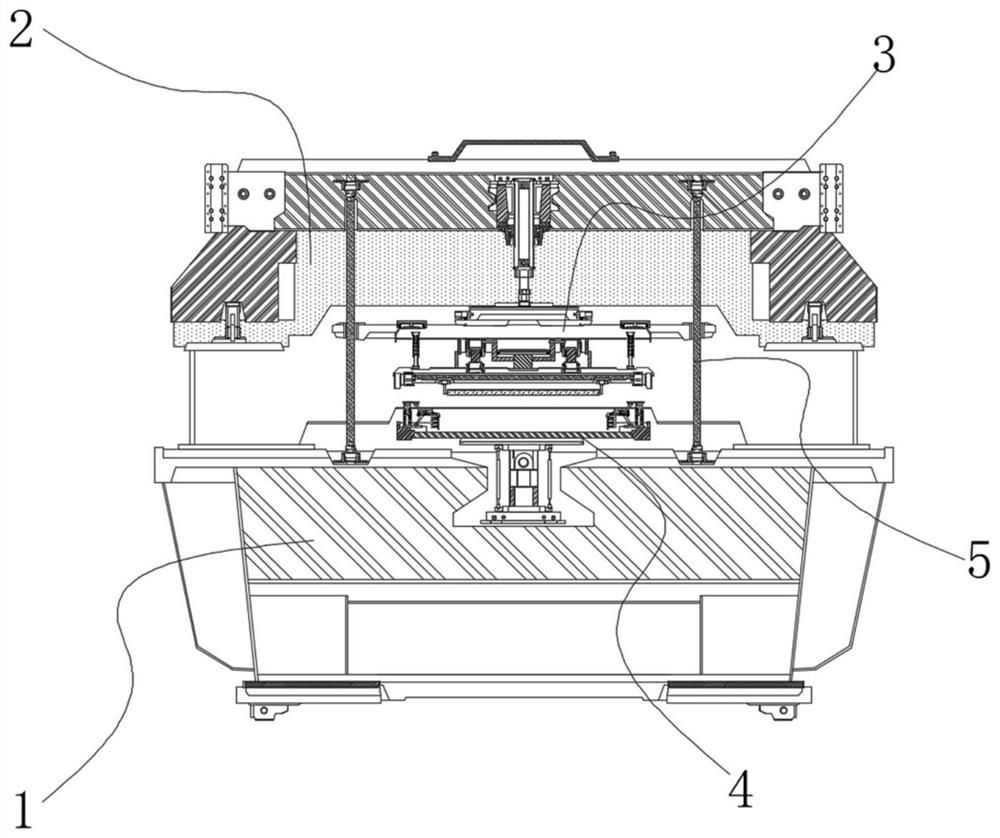

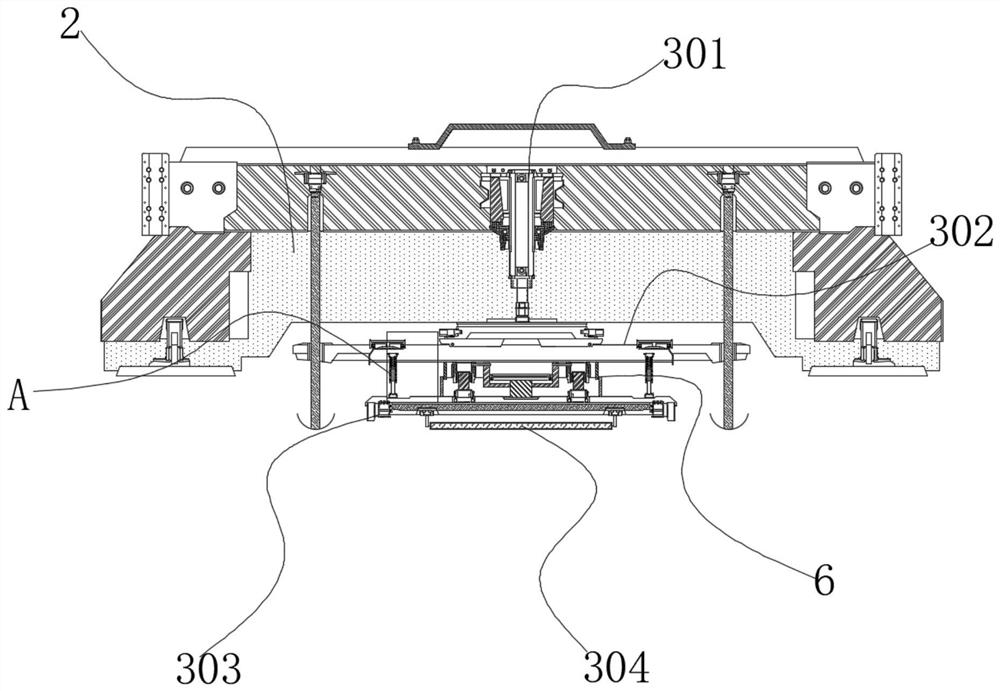

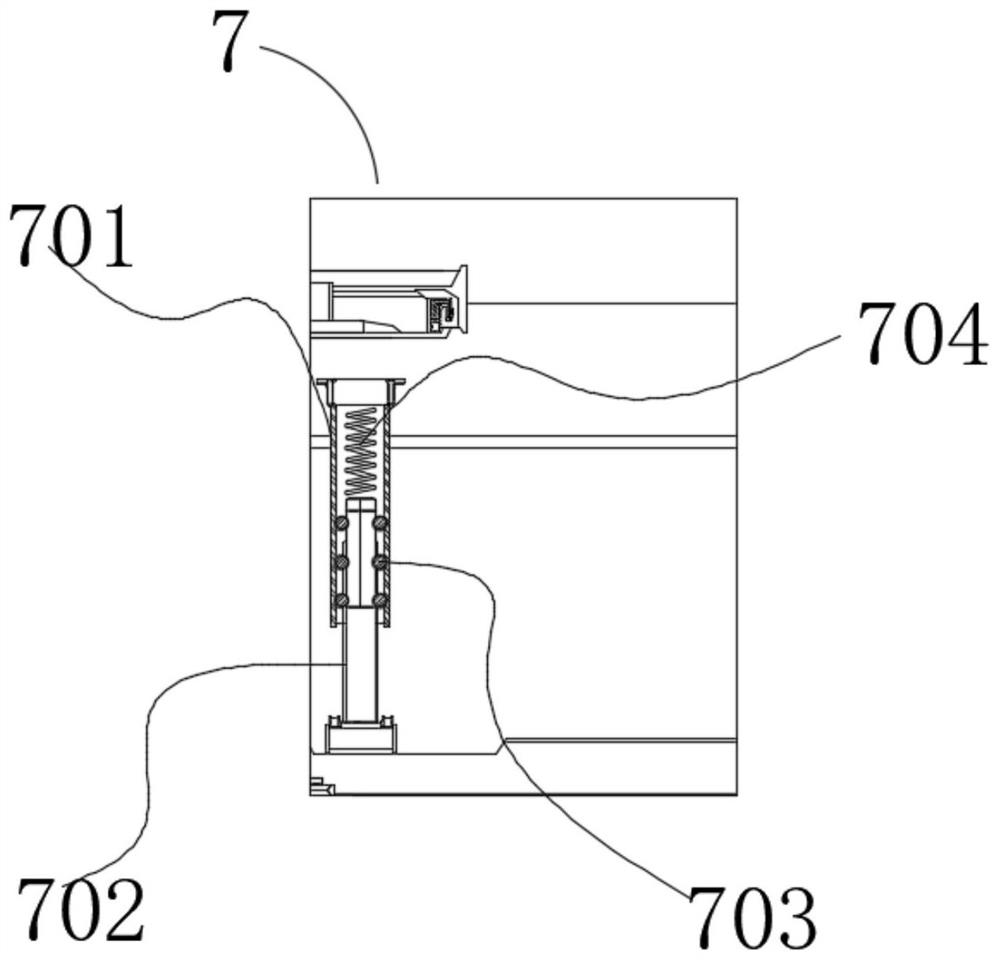

[0034] refer to figure 1 , the present invention provides a technical solution: an outer plate stamping and forming machine for computer case production, which includes a working base 1, an upper mounting body 2, an upper stamping die assembly 3, a lower bearing assembly 4, and side guide pillars 5 , wherein, the middle part of the upper end surface of the working base 1 is equipped with an upper mounting body 2, and the left and right sides of the upper mounting body 2 are connected and fixed with the working base 1 by locking bolts, and the upper mounting body 2 There is a limit notch for inlaying and fixing the side guide pillar 5, one end of the side guide pillar 5 extends into the limit notch, and is symmetrically and vertically embedded and fixed on the upper installation body 2; An upper stamping die assembly 3 is vertically arranged on the inner middle side of the upper mounting body 2;

[0035] The upper stamping die assembly 3 stamps and molds the computer case plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com