Aluminum alloy radiator base copper sheet embedding device

A technology of embedding device and base copper, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as arm soreness, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

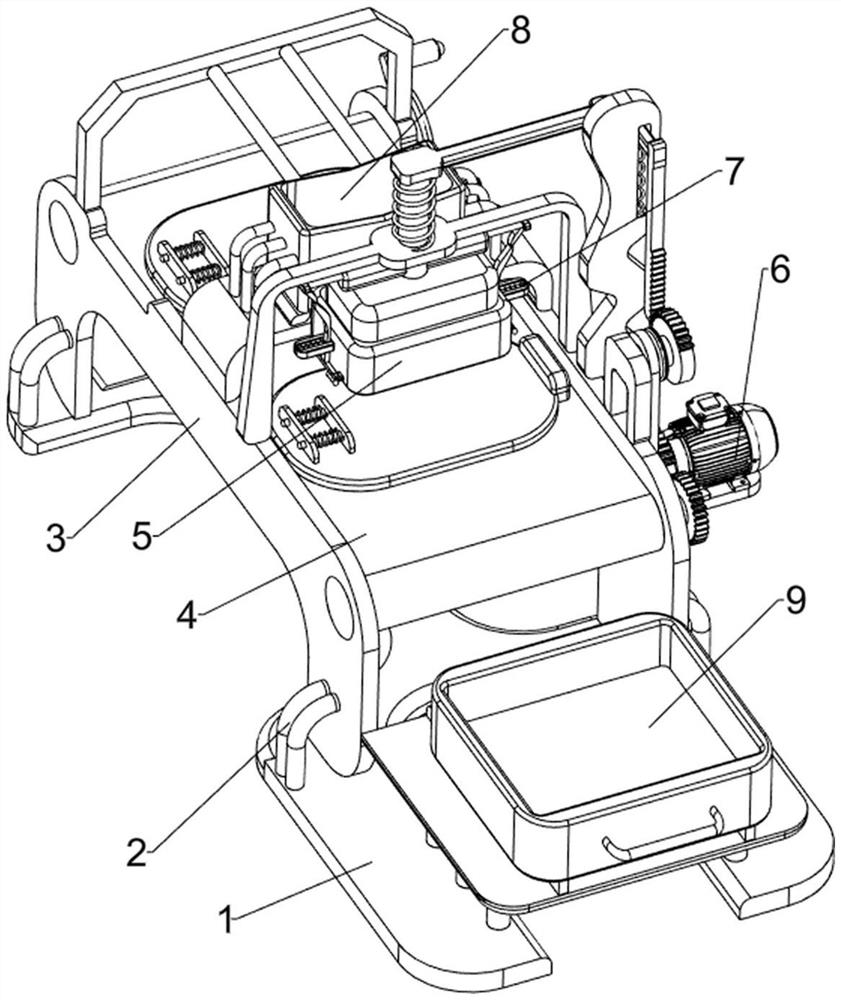

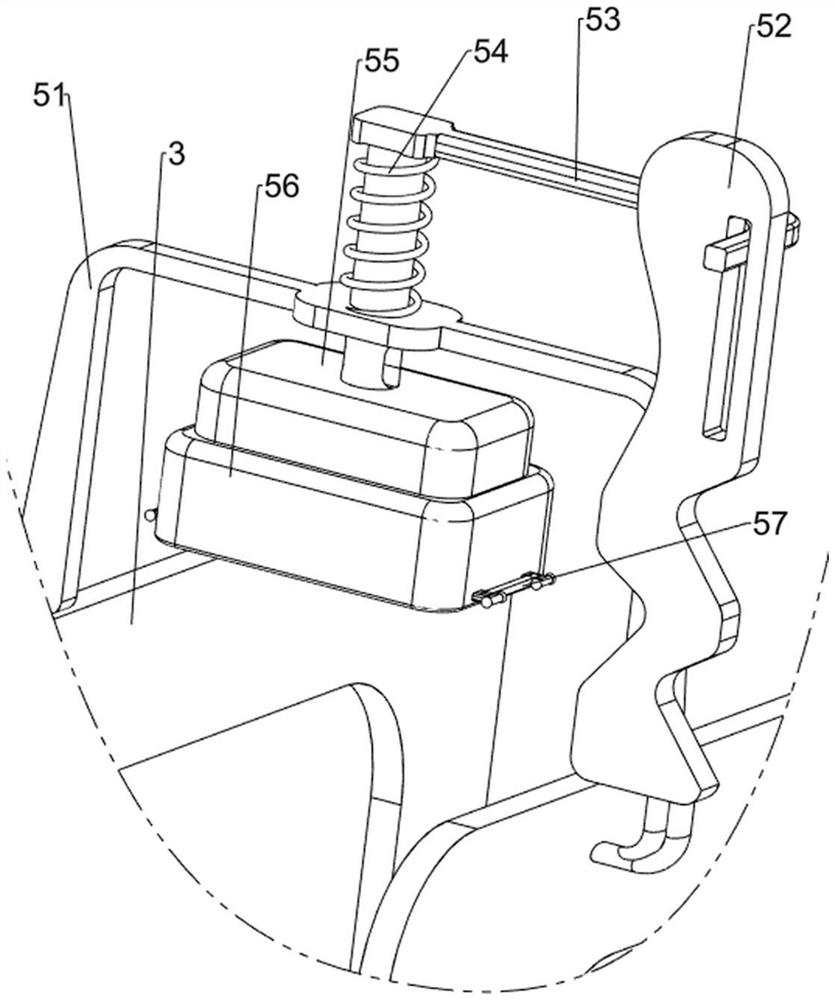

[0069] An aluminum alloy radiator base copper sheet embedding device, such as Figure 1-3 As shown, it includes a base 1, a first support rod 2, a first support frame 3, a transmission mechanism 4, and an extruding mechanism 5. The four sides of the base 1 are provided with first support rods 2, and the longitudinal first support rods 2 Each of them is connected with a first support frame 3, a transmission mechanism 4 is arranged between the first support frames 3, and an extruding mechanism 5 is arranged between the first support frames 3.

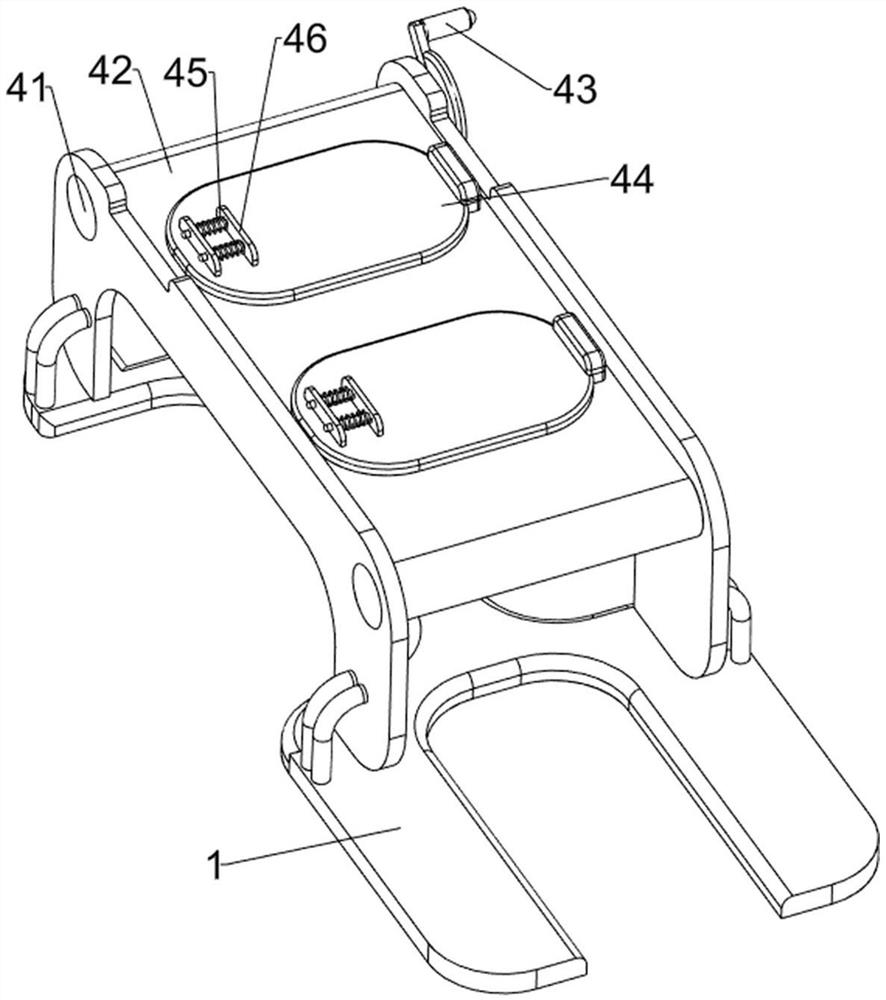

[0070] The transmission mechanism 4 includes a drum 41, a conveyor belt 42, a first handle 43, a discharge plate 44, a first spring 45, and a sliding frame 46, and the front and rear sides of the first support frame 3 are rotatably connected with a drum 41. A conveyor belt 42 is connected between them, a first handle 43 is provided on the right side of the rear drum 41, a discharge plate 44 is uniformly arranged on the conveyor belt 42, a...

Embodiment 2

[0074] On the basis of Example 1, such as Figure 4-7 As shown, a rotating mechanism 6 is also included, and the rotating mechanism 6 includes a first fixed block 61, a motor 62, a first missing gear 63, a full gear 64, a transmission assembly 65, a first rotating shaft 66, a second missing gear 67, a tooth Bar 68 and the third spring 69, the first support frame 3 right front side on the right side is provided with the first fixed block 61, and the first fixed block 61 top is provided with motor 62, and motor 62 output shaft is connected with the first missing gear 63, front The right side of the drum 41 on the side is provided with a full gear 64, the first missing gear 63 meshes with the full gear 64, and the right front side of the first support frame 3 on the right side is rotatably connected with a first rotating shaft 66, and the first rotating shaft 66 is provided with a second rotating shaft. Two missing gears 67, a transmission assembly 65 is connected between the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com