Automatic firewood chopping equipment

A firewood chopping and equipment technology, applied in the field of automatic firewood chopping equipment, can solve the problems of low work efficiency, labor-intensive, long working hours, etc., and achieve the effect of convenient firewood chopping and saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

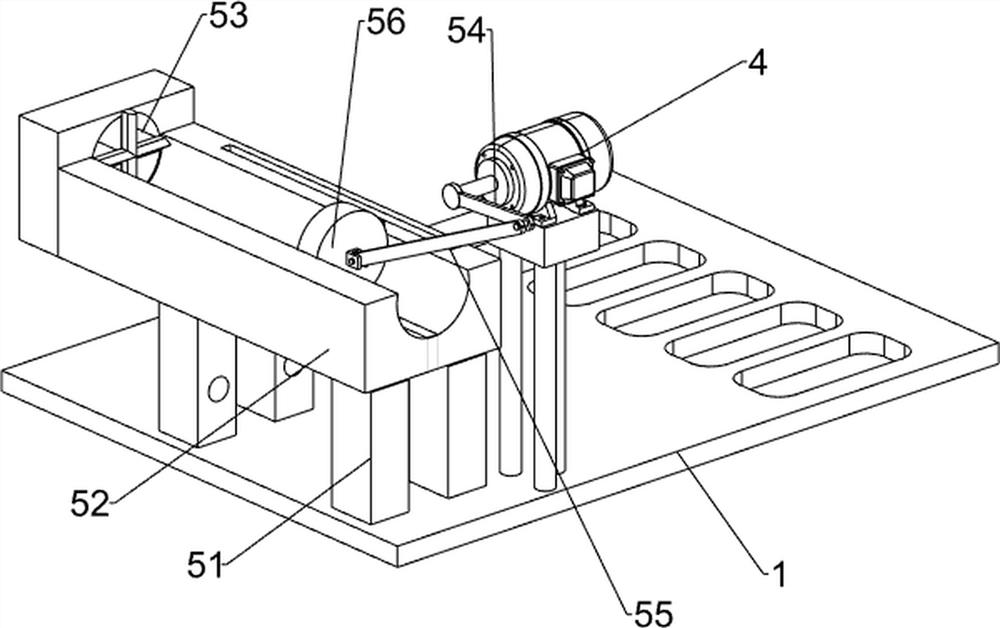

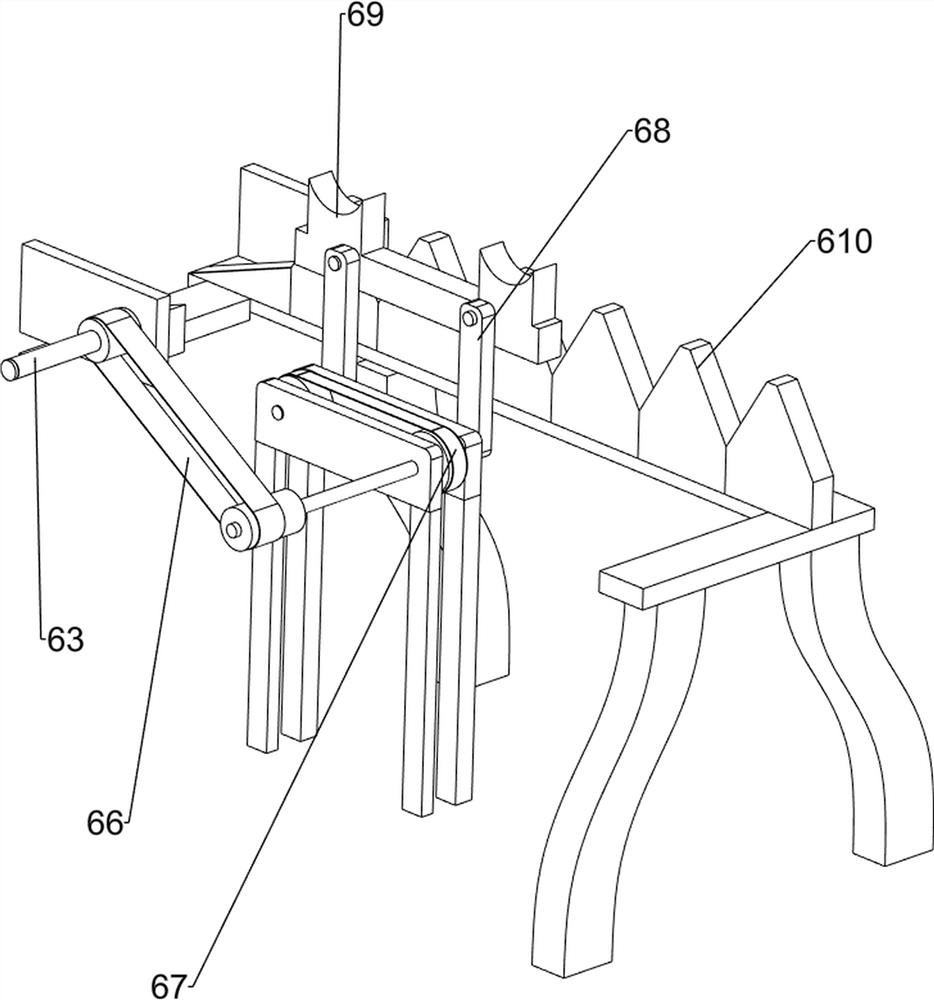

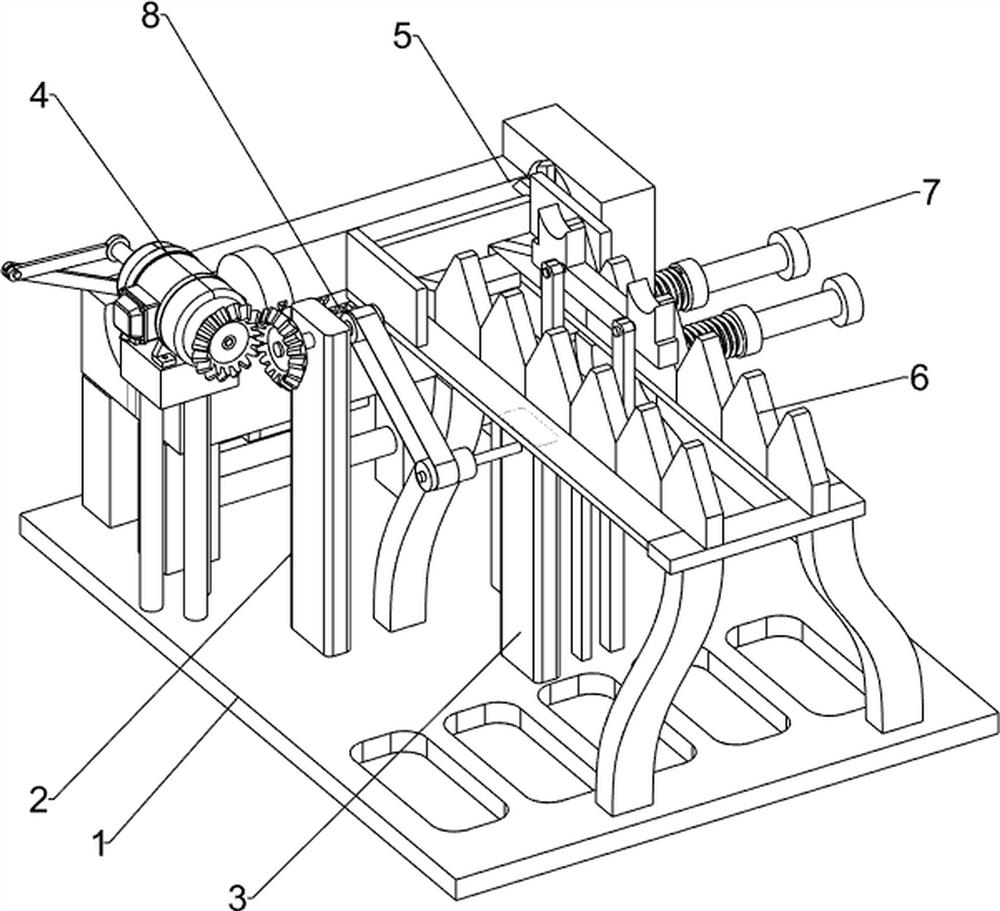

[0022] An automatic wood chopping device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a base plate 1, a first column 2, a second column 3, a motor 4, a splitting mechanism 5, and a transport mechanism 6. A second column 3 is provided, a motor 4 is installed on the front side of the upper left part of the base plate 1, a splitting mechanism 5 is provided on the upper left part of the base plate 1, the splitting mechanism 5 and the motor 4 are arranged, and a transport mechanism 6 is provided on the upper right part of the base plate 1. The transport mechanism 6 is connected with the motor 4, and the transport mechanism 6 cooperates with the splitting mechanism 5.

[0023] When people use the present invention to chop firewood, people first put the firewood on the transport mechanism 6, then start the motor 4, the motor 4 drives the transport mechanism 6 to move, the transport mechanism 6 transports the firewood to the...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , Figure 5 and Figure 6 As shown, it also includes a receiving mechanism 7. The upper left part of the base plate 1 is provided with a receiving mechanism 7. The receiving mechanism 7 includes a connecting rod 71, a storage box 72 and a first compression spring 73. Two grounds on the left and right sides The lower part of the foot 51 is provided with a connecting rod 71, and the two connecting rods 71 are slidingly provided with a storage box 72. A compression spring 73 is connected with the connecting rod 71 and the storage box 72 .

[0030]When the push block 56 resists the firewood and drives the firewood to move towards the cross knife 53, and the push block 56 moves backwards to contact the storage box 72, the push block 56 pushes the storage box 72 to move backward. At this time, the first compression spring 73 becomes In the compressed state, the storage box 72 catches the fallen firewood. After the firewood is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com