A construction method for the roof of the sealed space on the top of the immersed tube

A technology of sealing space and construction method, which is applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of increasing the construction time of the immersed tube roof, scaffolding cannot be reused, and increasing construction costs, so as to shorten the construction time and reduce the The effect of construction cost and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

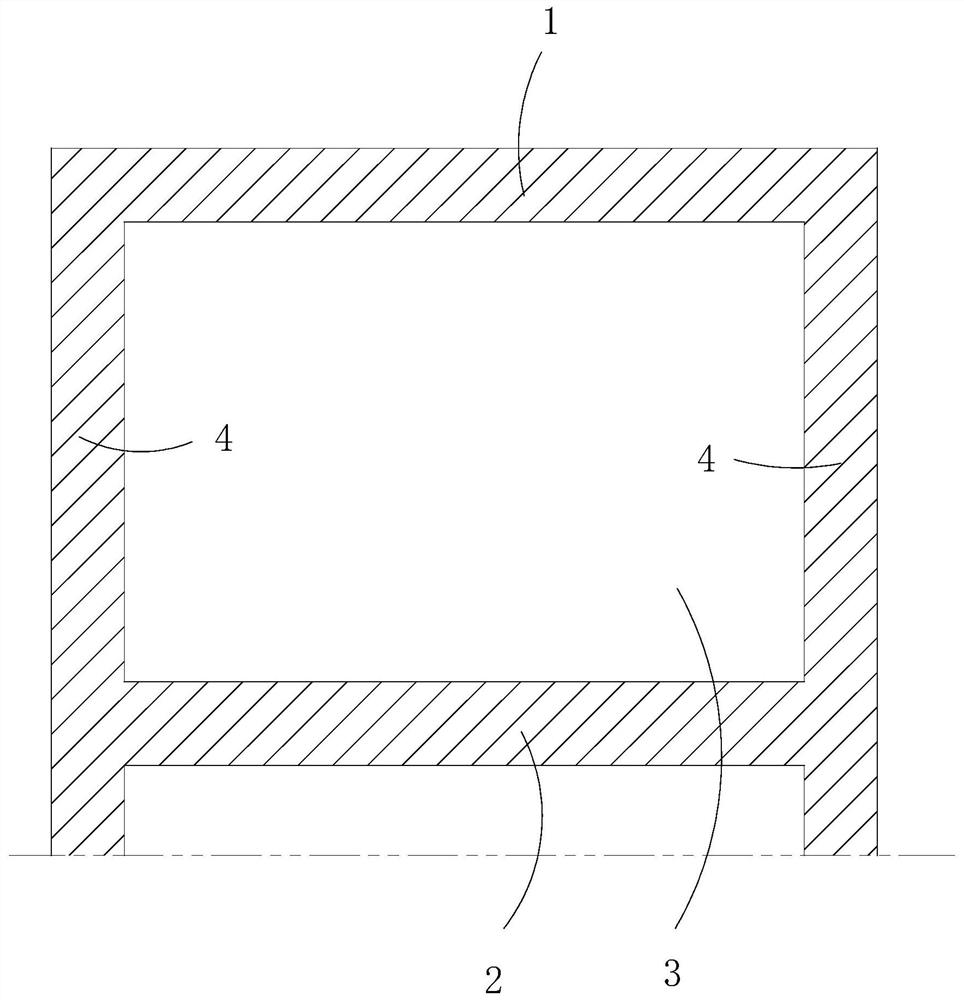

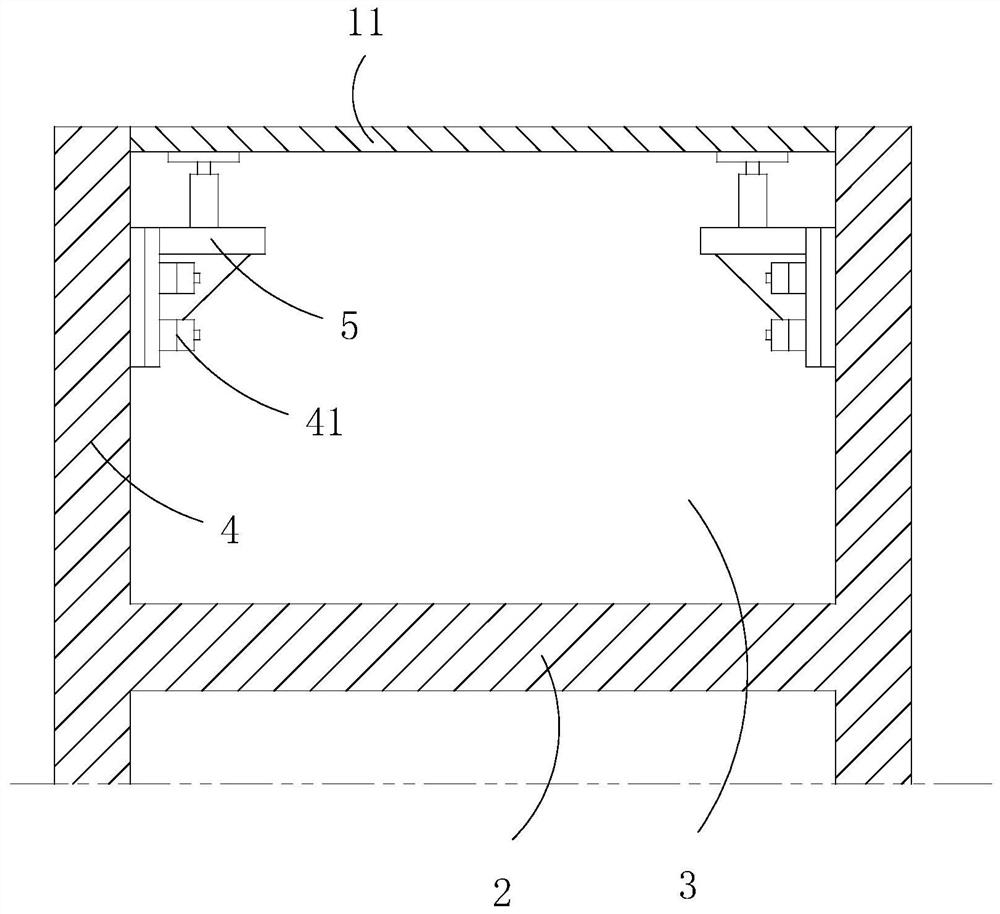

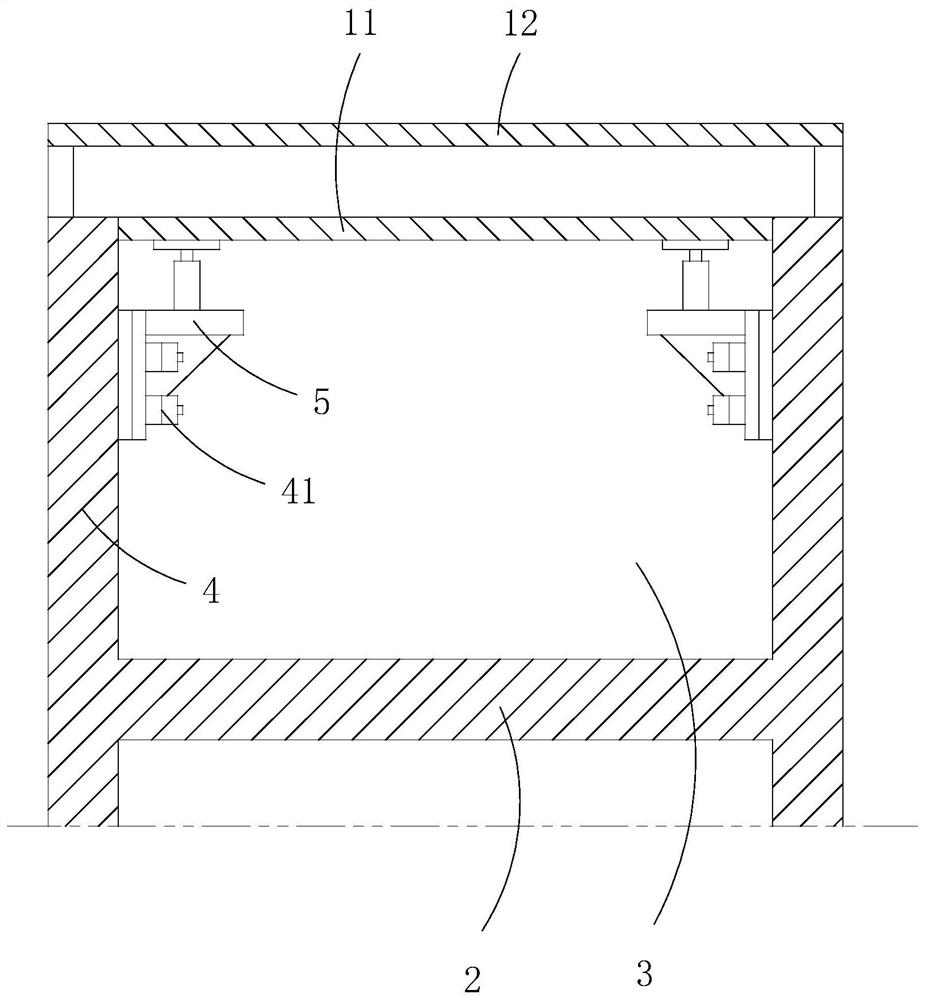

[0039] like Figure 2-4 As shown, a construction method for the top plate of the sealed space at the top of the immersed tube includes the following steps:

[0040] S1. pouring the side wall 4, and pre-embedding a connector 41 on the side wall 4, and the connector 41 is located on the upper part of the side wall 4;

[0041] S2. Make the support structure 5, and connect the support structure 5 with the connector 41, so that the support structure 5 is located in the lattice space 3;

[0042] S3. construct the bottom mold 11 for pouring the upper roof 1 on the support structure 5, and use the support structure 5 to support the bottom mold 11;

[0043] S4. The top mold 12 is constructed above the bottom mold 11, so that a pouring space for forming the upper top plate 1 is formed between the bottom mold 11 and the top mold 12;

[0044] S5. The upper roof 1 is formed by pouring.

[0045] In the above solution, the support structure 5 is connected with the connecting member 41 in ...

Embodiment 2

[0050] like Figure 5 and 6As shown, in the construction method for the top plate of the sealed space at the top of the immersed tube described in this embodiment, the middle of the bottom mold 11 is in a suspended state, so the gravitational bending moment of the bottom mold 11 increases continuously from the middle to the two ends. Therefore, the difference between the solution of this embodiment and the embodiment 1 is that the bottom mold 11 includes a horizontally arranged support plate 13, and the bottom of the support plate 13 is provided with an arch part 14, and the arch part 14 is One end is connected to one of the supporting structures 5 , the other end is connected to the supporting structure 5 on the opposite side wall 4 , and the arched member 14 is supported and connected to the supporting plate 13 .

[0051] On the basis of the above, in a further preferred manner, the arched member 14 is a space truss structure, so that under the same strength, the structural...

Embodiment 3

[0054] like Figure 4 and 6 As shown, the construction method for the top plate of the sealed space at the top of the immersed tube described in this embodiment is different from Embodiment 1 or 2 in that the support structure 5 includes a base 51, and the base 51 is provided with There is a lifting mechanism 52, and the top of the lifting mechanism 52 is connected with a support table 53 for supporting the bottom mold 11;

[0055] The step S3. constructing the bottom mold 11 for pouring the upper roof 1 on the support structure 5, and using the support structure 5 to support the bottom mold 11, specifically:

[0056] S31. construct the bottom mold 11 for pouring the upper roof 1 on the support structure 5;

[0057] S32. Place the bottom mold 11 on the support table 53;

[0058] S33. Adjust the lifting mechanism 52 to make the bottom mold 11 reach a predetermined height.

[0059] The beneficial effect of this embodiment is that the position and height of the support table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com