A pin transfer transport device

A transport device and pin shaft technology, applied in the field of pin shaft transfer transport devices, can solve the problems of unfavorable economy and flexibility of forklifts, scratches on the paint surface, and unfavorable selection and use by users, and achieve convenient storage, convenient storage and The effect of taking out, strong practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

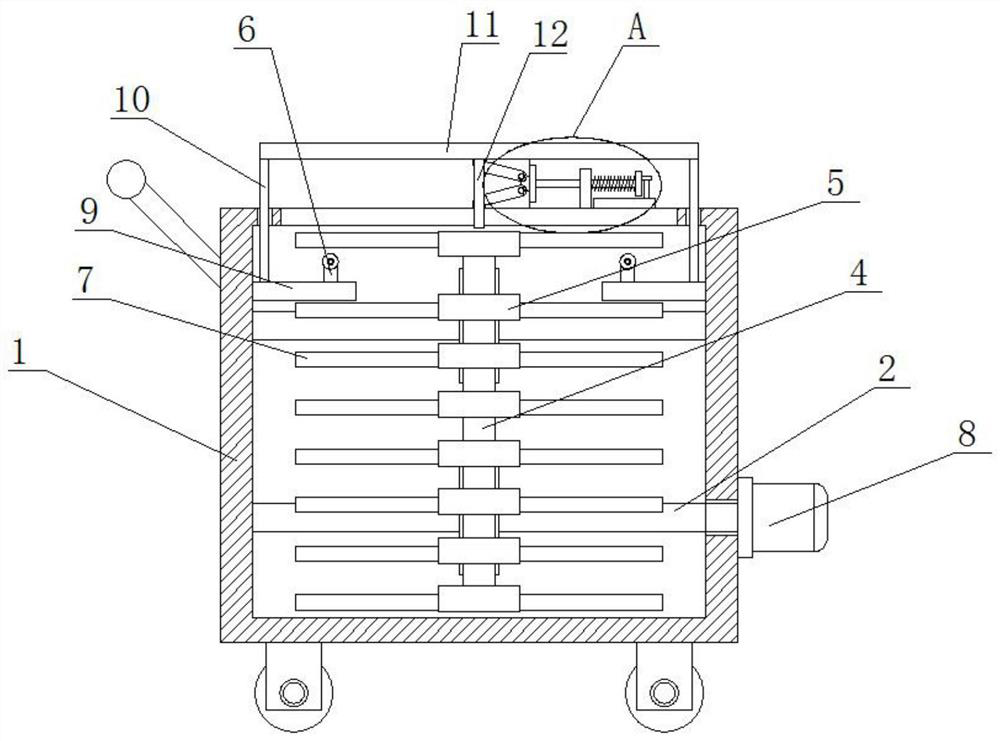

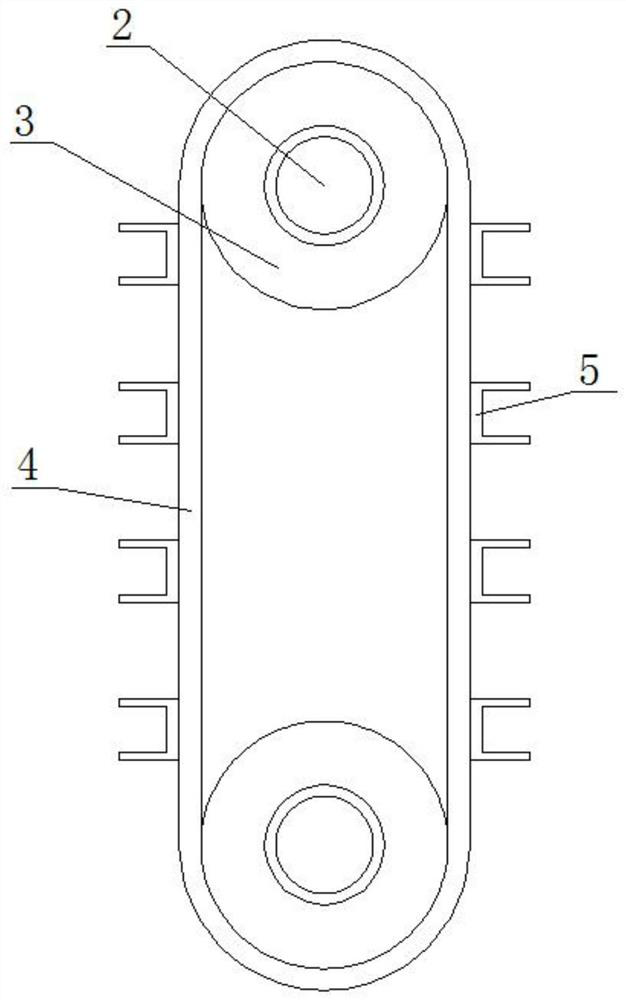

[0025] refer to Figure 1-5 , In this embodiment, a pin shaft transfer and transportation device is proposed, including a transportation box 1. Wheels are rotatably connected to the bottom four corners of the transportation box 1, and a handle is fixedly installed on the top of one side of the transportation box 1. The transportation box 1 There are two rotating shafts 2 symmetrically connected to the inner wall of the transport box 2, and a turntable 3 is fixedly installed on the two rotating shafts 2. The two turntables 3 are connected with the same transmission belt 4 for transmission. The bottom of the other side of the transport box 1 is fixedly installed with a drive The motor 8, and the driving motor 8 is fixedly connected with one end of the rotating shaft 2 located below, and a plurality of U-shaped plates 5 are fixedly installed on the transmission belt 4 at equal intervals. The pin shaft 7 is installed, the top inner wall of the transport box 1 is provided with a ta...

Embodiment 2

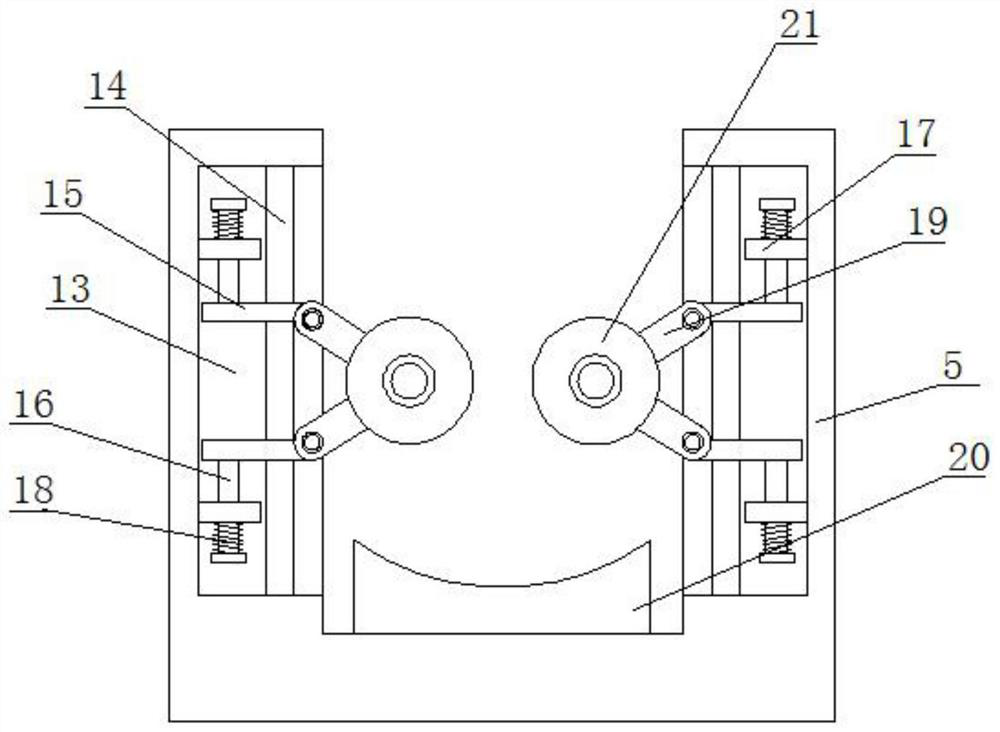

[0028] In this embodiment, the clamping assembly includes connecting grooves 13 formed on the inner walls of both sides of the U-shaped plate 5 , and two sliding plates 15 are symmetrically slidably connected in the connecting groove 13 , and one side of the two sliding plates 15 is connected by rotation. There is a connecting rod 19, and one end of the two connecting rods 19 extends to the outside of the connecting groove 13 and is rotatably connected with the same limit wheel 21, the limit plate 20 is fixedly installed on the inner wall of the U-shaped plate 5, and the two limit Both the position wheel 21 and the limit plate 20 are clamped with the pin shaft 7 , and the pin shaft 7 can be easily clamped by using the two limit wheels 21 and the limit plate 21 .

[0029] In this embodiment, the sliding rod 14 is fixedly installed on the inner wall of the connecting groove 13 , and the two sliding plates 15 are both slidably sleeved on the sliding rod 14 , and two fixed plates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com