Spherical lander and planet landing method using spherical lander

A lander, spherical technology, applied in the direction of space vehicle landing device, system of space vehicle return to the earth's atmosphere, etc., can solve the problems of fuel consumption, lander stability, poor safety, easy to fall, etc., to improve stability performance and the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

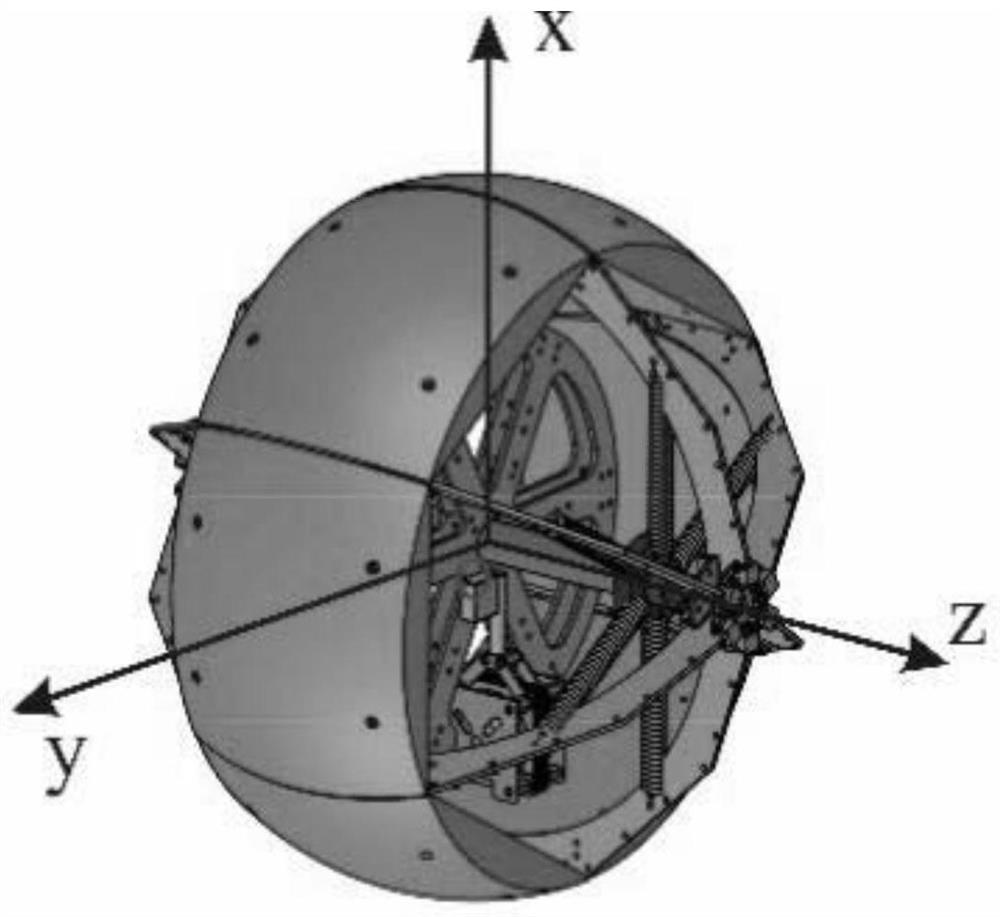

[0042] Specific Embodiment 1: A spherical lander in this embodiment includes: the spherical lander includes a spherical shell and an eccentric plate;

[0043] The spherical shell is composed of six frame rods and a cover plate, and the cover plate covers the six frame rods and wraps the six frame rods;

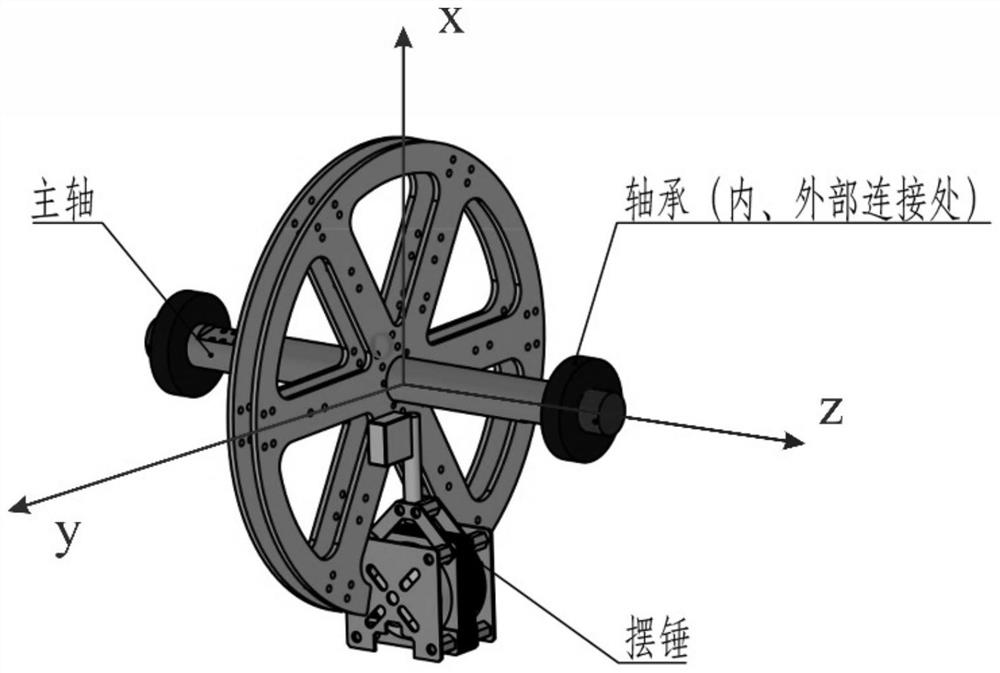

[0044] The eccentric disc includes disc, bearing, main shaft and pendulum; the eccentric disc structure (such as figure 1 , image 3 );

[0045] The disk is divided into six hollow areas according to the central angle, the central angle of each hollow area is 60 degrees, and one of the hollow areas lacks the bottom edge of the arc;

[0046] The main shaft runs through the center of the disc and is set perpendicular to the disc surface;

[0047] The bearing sleeves are located at both ends of the main shaft and are set concentrically with the main shaft;

[0048] The pendulum is installed at the center of the eccentric disc;

[0049] The center of gravity of the eccentric ...

specific Embodiment approach 2

[0052] Embodiment 2: This embodiment differs from Embodiment 1 in that the eccentric plate is connected to the spherical shell through a separation mechanism, so that the direction of the pendulum is consistent with the direction of the thruster or paraglider.

[0053] Before the separation mechanism is unlocked, the eccentric plate is fixedly connected with the spherical shell; after the separation mechanism is unlocked, the eccentric plate is rotatably connected with the spherical shell, and the spherical shell can freely rotate around the main axis (z axis) relative to the eccentric plate.

[0054] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

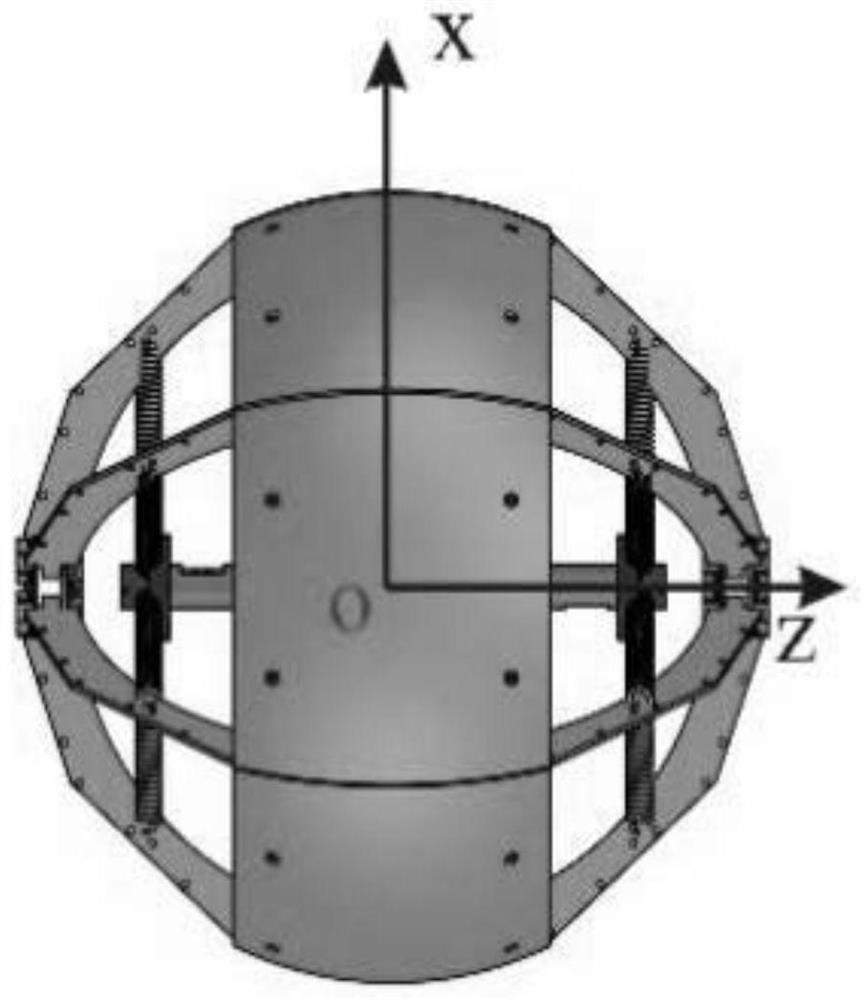

[0055] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the separation mechanism is installed at the shortest distance between the six support rods and the eccentric plate.

[0056] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com