Concrete small box girder assembly type shear-resistant reinforcing device based on UHPC prefabricated slab and reinforcing method of device

A technology of reinforcement devices and prefabricated panels, applied in the direction of bridge reinforcement, erection/assembly of bridges, bridges, etc., can solve the problems of harsh health conditions, difficulty in achieving the expected reinforcement effect, etc., and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

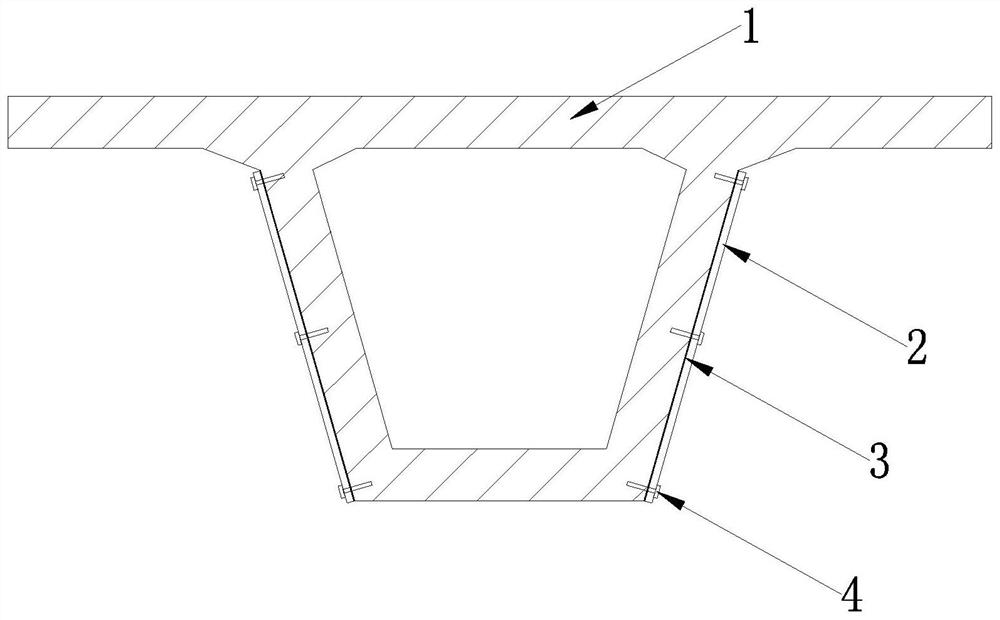

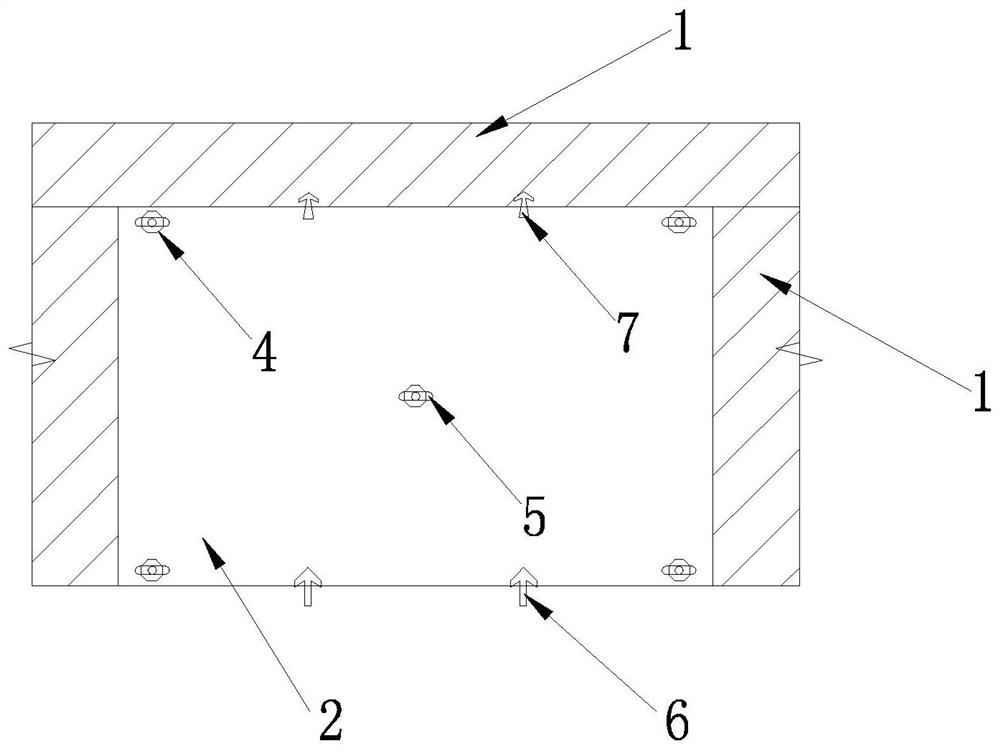

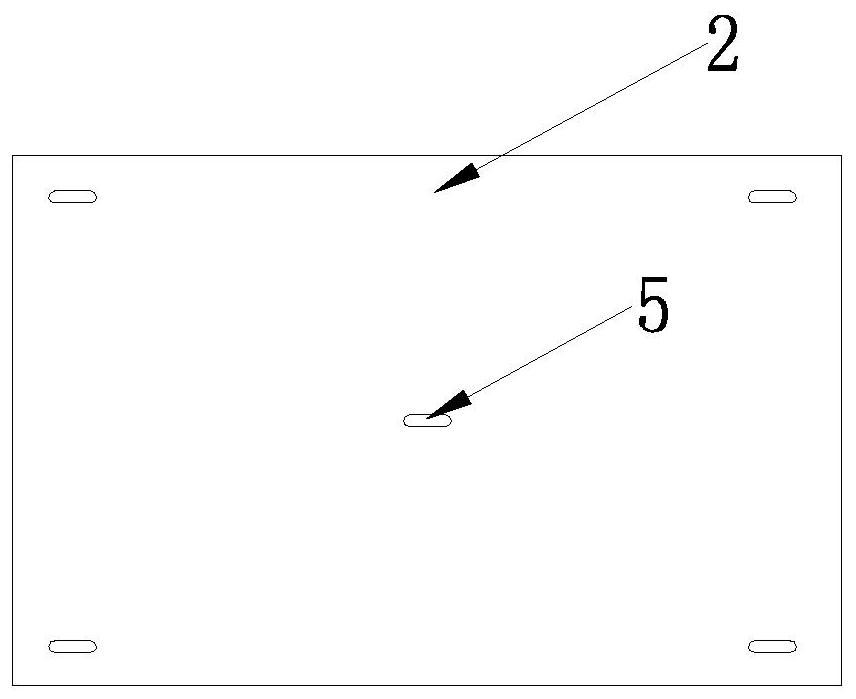

[0034] Such as Figure 1~4 As shown, a prefabricated UHPC slab-based shear reinforcement device for concrete small box girders includes a UHPC prefabricated slab 2 assembled on the outer surface of the small box girder 1; Correspondingly, the small box girder 1 is embedded with anchor bolts 4 corresponding to the anchor bolt reserved holes 5, and the anchor bolts 4 are inserted into the anchor bolt reserved holes 5 and fastened by bolts. It is used to attach the UHPC prefabricated panel 2 to the outer surface of the small box girder 1.

[0035] The invention provides an assembled shear reinforcement device for small concrete box girders based on UHPC prefabricated slabs. The UHPC prefabricated slabs are prefabricated in the factory, and the cross-section resistance of the small concrete box girder webs is increased by using glue injection after direct installation on site. Shear reinforcement. By prefabricating UHPC prefabricated panels and on-site assembly construction, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com