Oil cooler module

An oil cooler, oil pump technology, applied in the direction of gear lubrication/cooling, membrane filter, chemical instruments and methods, etc., can solve the problems of increasing the cost of components, increasing the types of components, etc., to achieve flexible pipelines, simple pipelines, cost effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

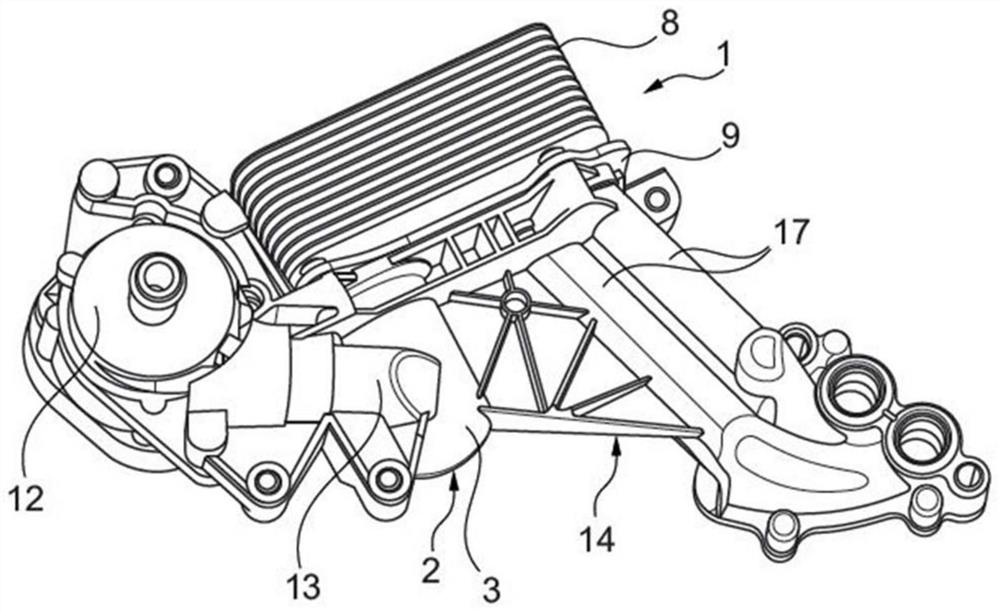

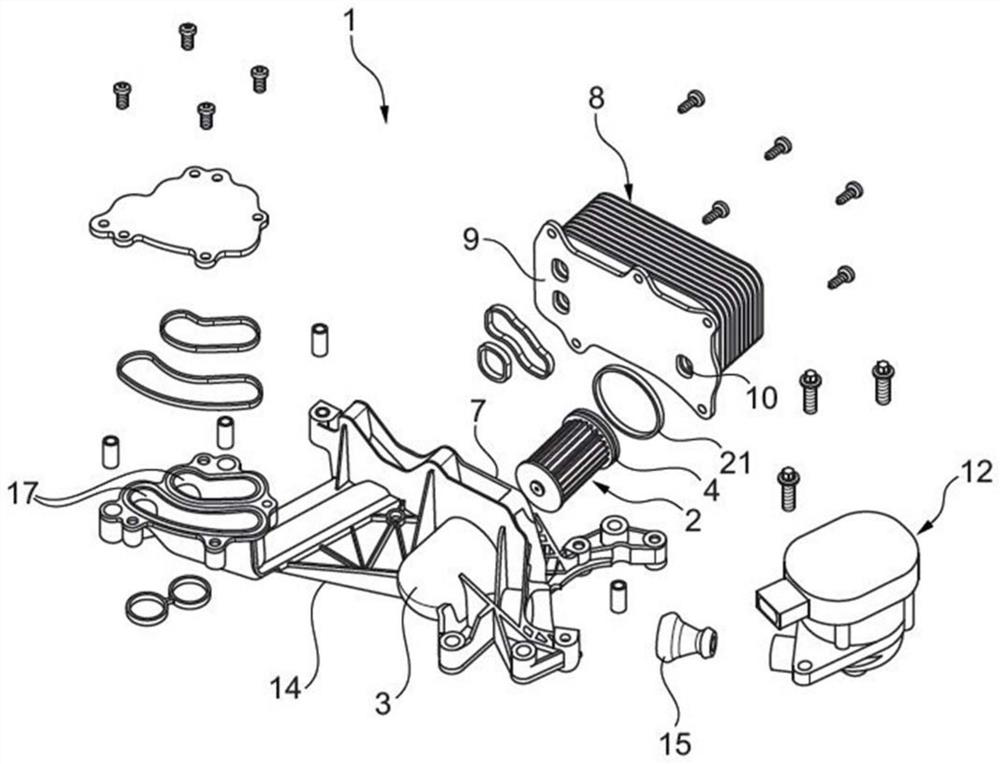

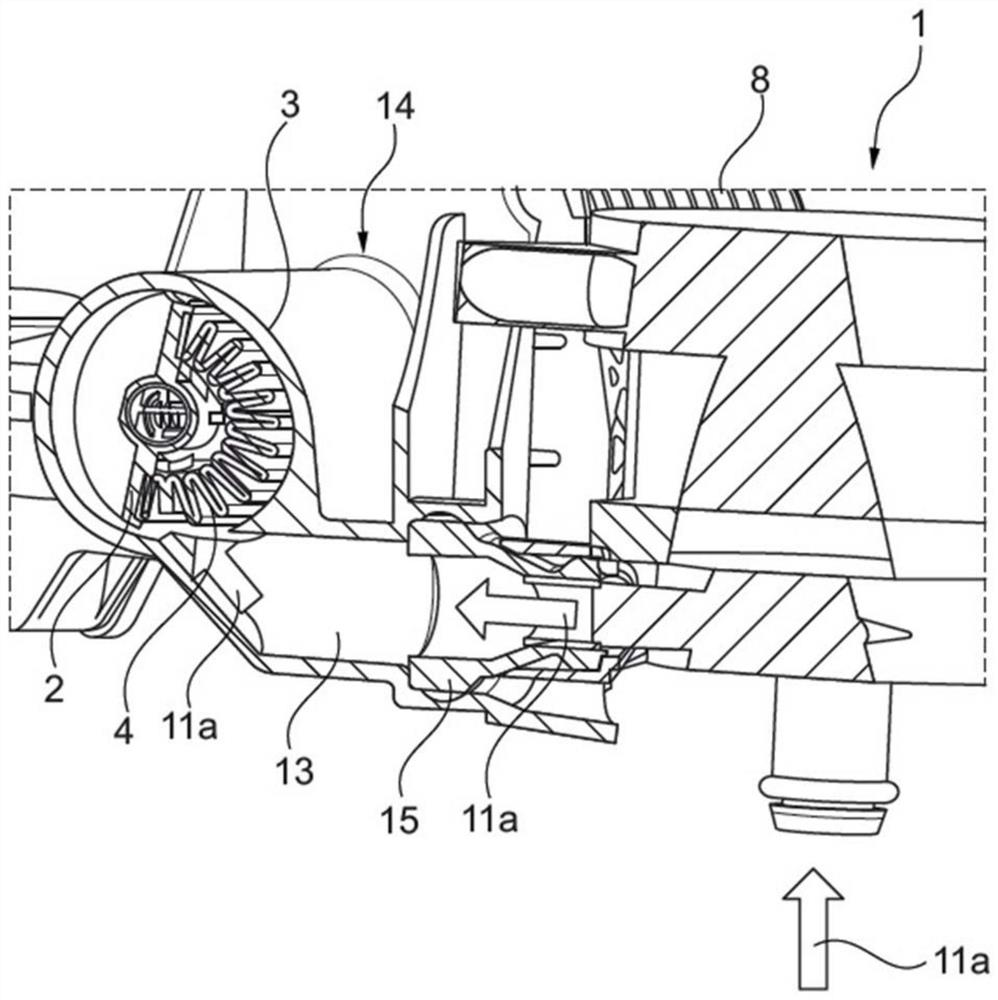

[0028] according to figure 1 7, the oil cooler module 1 according to the invention, which can be formed, for example, as a gear oil cooler, comprises a filter device 2 with a filter housing cavity 3 in which the Ring filter element 4 with raw side 5 separated from clean side 6 . In this case, the filter housing cavity 3 has an opening 7 for inserting the ring filter element 4 . Also provided is a heat exchanger 8 (for example a plate heat exchanger) comprising a base plate 9 for temperature control of a fluid, especially oil. According to the invention, the filter device 2 is now directly and tightly connected via its filter housing cavity 3 to the base plate 9 of the heat exchanger 8, so that the base plate 9 closes the opening 7 of the filter housing cavity 3 (see also in particular Fig. 6 to 7).

[0029] With the oil cooler module 1 according to the invention, it is therefore now possible for the first time to filter the filter device 2 which has hitherto been constructe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com